Durée de vie de la batterie d’un chariot élévateur : plomb-acide ou lithium

Table des matières

- Durée de vie de la batterie d’un chariot élévateur : plomb-acide ou lithium

Durée de vie de la batterie du chariot élévateur : types de batteries

There are two main types: the forklift lead acid battery and the lithium forklift battery. Both of them have unique features that govern their life span and how they will impact the forklift efficiency.Batterie au plomb pour chariot élévateur

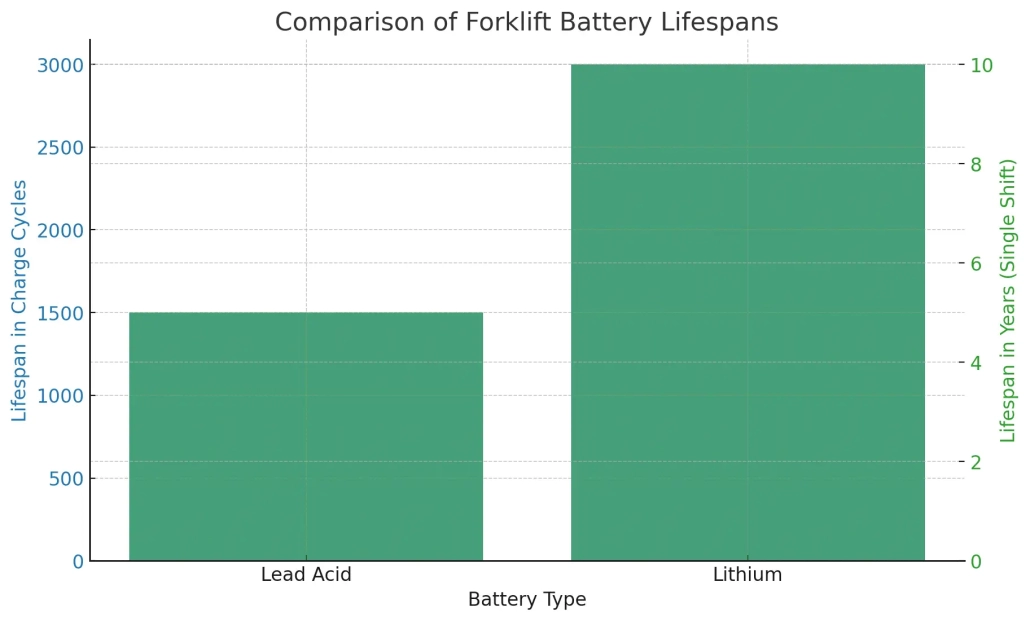

This type of battery has been in use since 1859. As such, it is time-tested and proven to be a solution to power forklifts. These batteries work through a chemical reaction that occurs with lead plates, producing electrical power with a mixture of sulfuric acid and water. This type of battery has been the industry standard for decades because of its dependability and lower upfront cost.What can probably be considered the most advantageous aspect of a forklift lead acid battery is the fact that it is cheap. The capital required to purchase this kind of battery is less than the capital required for a lithium battery. However, they have some significant cons. Forklift lead-acid batteries are weighty and cumbersome in size; hence, handling them is a challenge. They are difficult to maintain, including the need to water the electrolyte levels. If poorly maintained, these batteries degrade fast and need replacement before their time. A major setback is the need for downtime during charging. This time-wasting process interrupts the activities since forklift lead acid batteries have to be taken out of the forklift for recharging. In addition, these batteries are not the best since they lose a certain amount of capacity over time due to the chemical reactions within them. This can lower the running times, hence a need to be charged more often and lower productivity.Batterie de chariot élévateur au lithium

These are new technology. They also have high energy density and are compact, storing lots of energy in a tiny space. The lithium batteries for forklifts do not need watering and are sealed; therefore, they do not require any maintenance. This is an excellent advantage over lead acid batteries for forklifts since it saves costs for regular maintenance work and the labor costs involved.One of the features that stand out with lithium forklift batteries is their fast charging capability. Such a battery can be partly charged in between breaks without necessarily affecting its life cycle. For example, a lithium forklift battery charges to 100% in just one or two hours. This flexibility allows running for very long periods, as these forklifts can be charged through minimal break periods without requiring very long downtime intervals. As for its lifespan, lithium forklift batteries can go up to over 3,000 cycles. It simply means they are more energy-efficient. It uses up to 30% less than forklift lead acid batteries; that is quite a considerable amount of saving in terms of energy and, therefore, the cost of operating them. They are also friendlier to the environment because they consume less power and hence fewer chemical maintenance trips are needed.However, lithium forklift batteries have a higher initial cost. Businesses will have to invest more capital initially, but in the long run, maintenance and energy savings might make that a moot point. Additionally, in warehouses that run their operations throughout the day or have multiple shifts, lithium forklift batteries can charge quickly and keep forklifts running continuously, making this a more cost-effective and time-efficient option.To summarize: forklift lead-acid batteries are cheap but have much money put into maintenance; they have a short life, whereas lithium forklift batteries are more expensive at the purchasing moment, but they have a longer life, less maintenance, and better efficiency; thus, the best choice in modern, high-demand warehouse operations.