Why Choose a Chinese Manufacturer for Lithium Batteries

Table of Contents

- Why Choose a Chinese Manufacturer for Lithium Batteries

- Why Work with Chinese Manufacturers for Lithium Batteries

- Types of Chinese Lithium Battery Manufacturers

- How to Find the Right Chinese Lithium Battery Manufacturer

- Key Factors for Evaluating Chinese Lithium Battery Manufacturers

- How to Build Long-Term Relationships with Chinese Manufacturers

- Conclusion

- Learn More About Battery

Why Work with Chinese Manufacturers for Lithium Batteries

When considering a lithium battery for your business, sourcing from Chinese manufacturers offers several key benefits. Whether looking for cost-effective production, cutting-edge technology, or global scalability, China remains a dominant player in the battery manufacturing sector. This guide explores why Chinese battery manufacturers are ideal for businesses seeking reliable, high-performance lithium batteries.1. The Advantage of Cost-Effective Production

One of the most compelling reasons to source lithium batteries from Chinese manufacturers is the cost savings. China's extensive manufacturing infrastructure, skilled labor force, and efficient production methods make it a cost-effective option for businesses of all sizes. With China's economy of scale, manufacturers can produce lithium batteries in high volumes at a fraction of the cost compared to Western counterparts.China's competitive pricing is a significant advantage for companies looking to produce wholesale battery solutions. Lower production costs enable businesses to obtain high-quality lithium batteries without compromising performance or durability, ensuring a higher profit margin. China's vast network of suppliers and manufacturers also allows for greater flexibility, ensuring businesses can meet varying production demands without dealing with long delays or inflated costs.Furthermore, China’s manufacturing capacity enables businesses to scale operations quickly. Whether you need small or large quantities of lithium batteries, Chinese manufacturers can deliver them efficiently, helping your company maintain a steady supply chain and meet customer demand at a competitive price.2. Innovation and Leadership in Battery Technology

China is at the forefront of advancements in lithium battery technology, with manufacturers continually innovating to meet the needs of industries like electric vehicles (EVs), renewable energy storage, and consumer electronics. Leading Chinese battery manufacturers such as CATL, MANLY Battery and BYD have invested heavily in research and development to enhance lithium batteries' performance, longevity, and safety.Chinese manufacturers have made significant strides in improving energy efficiency and battery life. They are pushing the envelope on energy storage solutions by focusing on next-generation technologies like solid-state and high-density lithium batteries. These innovations are crucial for industries that rely on efficient and long-lasting power sources, such as solar energy storage systems and electric transportation.Chinese battery manufacturers also lead the way in producing lithium batteries with improved thermal management and enhanced safety features, essential for applications in electric vehicles and energy storage solutions. This focus on cutting-edge technology ensures that Chinese lithium battery manufacturers can meet the growing demand for high-performance batteries in diverse industries.3. Global Presence and Industry Impact

China has become the undisputed leader in the global lithium battery market. Its manufacturers supply batteries for a wide range of applications, including electric vehicles, solar energy systems, and consumer electronics. Chinese battery manufacturers dominate domestic markets and play a critical role in powering global industries. Companies like CATL, BYD, and CALB are recognized worldwide for their high-quality lithium batteries, integral to the transition toward clean energy.For businesses involved in the electric vehicle (EV) sector, Chinese lithium battery manufacturers are key players in supplying batteries for some of the world’s most well-known EV brands. Moreover, China’s leading position in the lithium battery market ensures that its manufacturers can meet the increasing demand for renewable energy storage solutions, contributing to the global shift toward sustainable energy.China's manufacturing expertise and vast production capacity have helped it maintain a dominant presence in the wholesale battery market. The country’s ability to produce lithium batteries at scale and competitive prices gives it a distinct advantage in supplying batteries for large projects, from utility-scale solar energy systems to large fleets of electric vehicles.

Types of Chinese Lithium Battery Manufacturers

When sourcing a lithium battery for commercial or industrial use, it's crucial to understand the types of Chinese manufacturers in this field. Each plays a distinct role in the global battery supply chain. Some specialize in custom-built packs, while others offer ready-made designs that businesses can quickly rebrand and deploy. This section breaks down the primary manufacturer types and introduces some top brands influencing the wholesale battery market worldwide.1. OEM (Original Equipment Manufacturers) in the Lithium Battery Industry

OEMs, or Original Equipment Manufacturers, produce lithium battery systems based on a client’s exact specifications. These manufacturers don’t market products under their name. Instead, they are the production engine behind well-known global brands in solar energy storage, electric vehicles, robotics, and more.International businesses prefer OEMs in China due to their:- Engineering flexibility (cell format, chemistry, BMS customization)

- Scalable production volume

- Familiarity with global certifications (UL, UN38.3, IEC62133)

2. ODM (Original Design Manufacturers) for Lithium Batteries

Unlike OEMs, ODMs design and manufacture battery systems in-house and then allow businesses to rebrand them. ODMs are the innovation drivers behind many plug-and-play wholesale battery packs used in solar, mobility, and backup power systems.A typical ODM in China offers:- Pre-engineered lithium battery packs

- Design options like custom branding, voltage tweaks, or casing materials

- Ready-to-ship units for B2B distributors or installers

| Category | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) |

|---|---|---|

| Design Ownership | The client provides the product design and technical specs | The factory designs the product; client simply rebrands |

| Customization Level | Highly customizable (battery specs, cell type, BMS, etc.) | Limited customization (logo, packaging, minor adjustments) |

| R&D Responsibility | Client is responsible for product development | Factory handles product R&D and engineering |

| Go-to-Market Speed | Longer development cycle; more back-and-forth | Faster launch with pre-engineered solutions |

| Ideal For | Businesses with in-house engineering teams or proprietary tech | Startups, integrators, or distributors needing turnkey products |

| MOQ (Minimum Order Quantity) | Typically higher; aligned with custom production needs | Usually lower; supports smaller batch orders |

| Cost Efficiency | Lower per-unit cost at scale but requires upfront investment | Lower upfront costs, but less design control |

| Example Use Case | A robotics company needs a custom 48V LiFePO4 battery with CANBus and thermal protection | A solar installer needs ready-to-ship 51.2V 100Ah battery packs with their own branding |

3. Key Players: CATL, BYD, and Other Leaders

China leads the global lithium battery race in output, innovation, quality, and market adoption. Here are some of the most impactful battery manufacturers in the industry:CATL (Contemporary Amperex Technology Co. Limited)

CATL is a dominant force in the EV and ESS markets, producing high-energy-density batteries for global automakers like Tesla and BMW. Their NMC and LFP technology breakthroughs have improved charge cycles, safety, and scalability. CATL also offers modular ESS solutions and advanced battery management systems.BYD (Build Your Dreams)

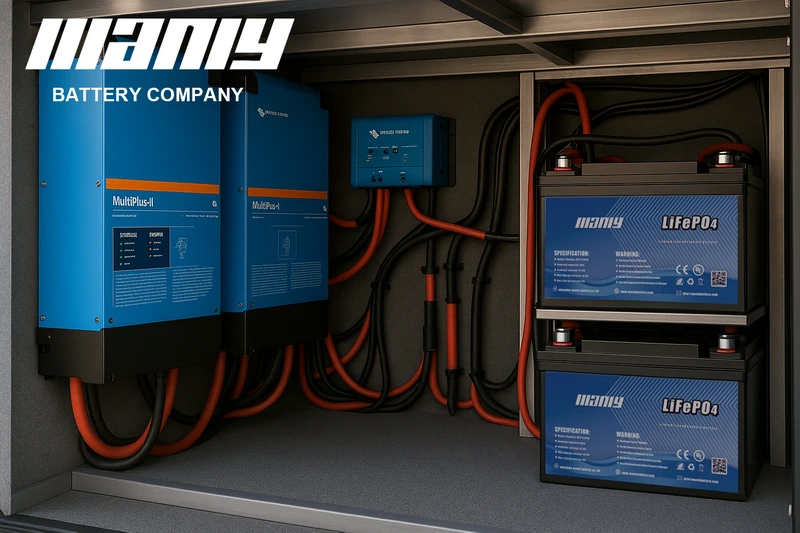

BYD manufactures batteries and electric vehicles, with its Blade Battery standing out for its LFP chemistry and structural safety. The company’s integration of battery, EV, and ESS technologies makes it a comprehensive player in clean energy adoption across Asia, Europe, and the Americas.MANLY Battery

MANLY Battery stands out among mid-sized Chinese manufacturers, especially in B2B. The company offers OEM and ODM services, specializing in 12V, 24V, 48V, and custom high-voltage lithium battery packs. These are widely used in:- Solar energy storage systems

- Automated guided vehicles (AGVs)

- Robotics and medical equipment

- Golf carts and marine applications

Other Notable Manufacturers

- CALB: Large-scale LFP and NMC battery producer for transportation and grid storage

- EVE Energy: Specializes in small-format lithium cells and innovative IoT power systems

- Guoxuan High-Tech: Focused on long-life LFP packs for EVs and commercial ESS

- Farasis Energy: Known for high-density battery modules and custom automotive cells

- SVOLT Energy: Offers AI-enhanced battery packs with integrated BMS and thermal controls

How to Find the Right Chinese Lithium Battery Manufacturer

Finding the right Chinese lithium battery manufacturer is essential to ensuring that your product meets high quality, safety, and performance standards. With many suppliers available, it's important to carefully evaluate potential manufacturers based on factors such as production capacity, certifications, and reputation. This section will guide you through the key steps to identify the ideal battery manufacturer for your business needs.1. Leveraging Online Marketplaces

One of the easiest ways to find a Chinese manufacturer is through online marketplaces. Platforms such as Alibaba, Made-in-China, and Global Sources are a gateway to a vast network of suppliers. They allow you to filter suppliers by key criteria such as customer reviews, certifications, and production capacity, providing a quick overview of potential partners.However, not all suppliers are created equal, so it’s essential to be thorough in your vetting process:- Certifications: Ensure the battery manufacturer holds relevant certifications, such as ISO 9001, UN38.3, or CE. These certifications confirm that the manufacturer meets international quality, safety, and environmental compliance standards.

- Customer reviews: Read feedback from past clients to assess the reliability and quality of the supplier’s products. Look for patterns in feedback to identify strengths or concerns.

- Request samples: Before committing to a large order, request samples to verify the quality and performance of the lithium battery.

2. Attending Trade Shows in China

Another highly effective method for sourcing reliable Chinese manufacturers is attending trade shows in China. Significant events like the Canton Fair and the Yiwu Commodities Fair are excellent opportunities to meet potential battery manufacturers face-to-face. These shows are packed with verified suppliers and allow you to examine products in person, making it easier to gauge quality and reliability.Benefits of attending trade shows include:- Direct product evaluation: You can physically inspect the lithium batteries and even test their performance.

- Meet manufacturers in person: Personal meetings allow one to ask technical questions and build trust with potential suppliers.

- Factory visits: Some suppliers may invite you to visit their manufacturing facilities, allowing you to assess their production capabilities and processes.

3. Using Verified Supplier Directories

In addition to online marketplaces and trade shows, supplier directories like SaleHoo and 1688.com can help you connect with reliable lithium battery manufacturers. These directories offer a curated list of credible suppliers, ensuring that you're working with a trustworthy partner.Key benefits of using supplier directories:- Pre-vetted suppliers: These directories usually screen suppliers for legitimacy and reliability, reducing the risk of dealing with fraudulent companies.

- Industry-specific filtering: Some directories specialize in specific industries, such as battery manufacturing, making it easier to find suppliers who meet your particular needs.

- Detailed company profiles: Supplier profiles often include information on certifications, product offerings, and customer reviews, helping you make an informed decision.

4. Evaluating Key Factors for Manufacturer Selection

When selecting a Chinese manufacturer for your lithium battery needs, there are several factors you should carefully consider:- Production capacity: Ensure that the manufacturer can meet your production needs, both in terms of quantity and timeliness.

- Certifications and standards: Verify that the manufacturer complies with essential safety and quality certifications, such as UN38.3 and IEC62133.

- Product quality: Assess the manufacturer's ability to meet your quality requirements through sample orders or feedback from past customers.

- Customer service and communication: Effective communication is key to a successful partnership. Ensure the manufacturer is responsive and easy to communicate with.

- Price and payment terms: While price is important, it should not be the only factor. Compare the overall value of different suppliers, considering product quality and reliability, not just the cost.

Key Factors for Evaluating Chinese Lithium Battery Manufacturers

Choosing the right Chinese manufacturers for your lithium battery supply chain isn’t just about price—it's about long-term reliability, product performance, and global compliance. Whether building an energy storage system or supplying batteries for electric vehicles, this guide walks you through the essential evaluation factors to help you make informed, confident decisions.1. What to Look for in Production Capacity and Certifications

A capable battery manufacturer must have the infrastructure to meet your demand and the documentation to back up their product quality.- Production Capacity: Check whether the supplier can handle your volume—especially if your project scales. Top-tier Chinese manufacturers typically produce over 1GWh annually.

- Global Certifications: Look for internationally recognized safety and performance credentials like UL, CE, UN38.3, and IEC62133. These ensure that the batteries meet essential standards in the U.S., EU, and other regulated markets.

- Product Specialization: Some manufacturers focus on specific verticals, such as solar energy storage or electric vehicles. Always align their technical strengths with your product’s end-use.

2. Cost, Lead Time, and Order Flexibility

Price is important—but it should never be the only factor. Balance cost with delivery reliability and order terms.- Cost Breakdown: Instead of comparing per-unit prices, evaluate the full landed cost: battery price, shipping, taxes, and tariffs. A slightly higher unit price sometimes results in better performance and fewer returns.

- Lead Time: Ask about manufacturing and shipping timelines. Typical lead time for wholesale battery orders can range from 15 to 45 days, depending on order size and production schedule.

- Minimum Order Quantity (MOQ): A flexible MOQ is vital to pilot new markets. Most Chinese wholesale suppliers have MOQs ranging from 50 to 500 units, but custom projects may require more.

- After-Sales Support: Reliable suppliers provide ongoing technical support, warranty coverage, and fast response times.

3. Comparing Top Chinese Lithium Battery Manufacturers

Here’s a quick comparison of top Chinese manufacturers in the lithium battery sector to simplify your supplier selection. We’ve focused on real-world performance metrics: energy density, cycle life, and certification coverage.| Manufacturer | Energy Density (Wh/kg) | Cycle Life (@80% DoD) | Global Certifications | Application Focus |

|---|---|---|---|---|

| CATL | 265 (NMC 811) | 3,000+ cycles | UL, UN38.3, IATF16949 | EVs, solar, commercial ESS |

| BYD | 240 (Blade LFP) | 4,500+ cycles | CE, UL, GB/T | EVs, public transit, storage |

| MANLY Battery | 250 (LFP/NMC Options) | 3,500+ cycles | UL, CE, UN38.3, MSDS | Solar, AGVs, robotics, custom B2B, Golf Cart, Boat, Lawn Mower |

How to Build Long-Term Relationships with Chinese Manufacturers

Building strong, lasting relationships with Chinese manufacturers is vital for your business's sustained success. By focusing on clear communication, starting small to test the waters, and fostering ongoing collaboration, you can ensure a steady and reliable partnership with your battery manufacturer. This section highlights the steps to build a relationship that stands the test of time.1. Clear Communication for Better Collaboration

Effective communication is the cornerstone of any successful business relationship, especially with Chinese manufacturers. Overcoming language barriers and time zone differences requires intentional strategies:- Be concise and direct: Clarity is key when working across different languages. Keep your messages short, using simple language and bullet points to avoid confusion. This will make it easier for your supplier to understand and act on your requests.

- Use visual aids: When discussing product specifications or addressing issues, visuals like diagrams, photos, or videos are invaluable. These tools help bridge gaps and ensure both parties are aligned in understanding the desired outcome.

- Embrace technology for real-time communication: WeChat, the dominant messaging app in China, can be a useful tool. It offers translation features that allow you and your supplier to communicate in your native languages. This is especially useful when direct verbal communication is necessary.

- Plan regular check-ins: Schedule regular calls or virtual meetings to track progress and clarify any points of concern. This helps both parties stay on the same page and ensures nothing is overlooked.

2. Starting Small to Build Trust

One of the most effective strategies when dealing with Chinese wholesale suppliers is to start small. This minimizes risk while allowing you to assess the quality and reliability of the battery manufacturer.- Test product quality: Before making a significant investment, start with a small order to verify that the products meet your standards. This is especially important for lithium batteries, where safety, performance, and longevity are critical. A sample order can give you a firsthand experience of the product's quality.

- Evaluate reliability: A smaller initial order will help you assess how well the manufacturer handles shipping, packaging, and customer service. It’s an opportunity to test their efficiency in meeting deadlines and delivering the promised product.

- Build trust incrementally: By starting small, you show the supplier that you are serious but also cautious, giving them a chance to prove their worth. As you see the results, you can gradually increase the volume of your orders.

3. Maintaining Strong Business Relationships

Once you’ve established a working relationship with your Chinese manufacturers, nurturing and maintaining that connection over time is essential. Here’s how you can ensure a successful long-term partnership:- Provide consistent feedback: Regular feedback helps your supplier understand your needs and make improvements. Whether it’s about product quality, delivery times, or packaging, consistent communication helps identify growth areas and shows that you’re invested in the partnership.

- Make factory visits: Visiting the manufacturer’s facility can deepen the relationship. A factory tour provides insight into their production process, quality control, and working conditions. It’s also an excellent opportunity to meet the team behind the product and ensure their operations align with your expectations.

- Recognize achievements and milestones: Acknowledge the manufacturer’s efforts when they deliver on time or exceed your expectations. Showing appreciation fosters goodwill and motivates your supplier to continue providing top-notch products and services.

- Flexibility in terms: As your relationship grows, consider being flexible with payment terms or order sizes. This flexibility shows you’re committed to a long-term relationship and can help the manufacturer prioritize your orders.

- Use detailed contracts: A clear contract is essential to avoid misunderstandings. Outline expectations for product quality, timelines, and any other important details. This creates a reference point for both parties and helps resolve potential issues quickly.