Automotive Batteries Are an Example of Which Hazard Class

Table of Contents

- Automotive Batteries Are an Example of Which Hazard Class

- What's the risk level of car batteries?

- Battery Disposal Alert: Navigating Hazardous Materials

- Navigating the Hazards: Smart Shipping for Automotive Batteries

- Identifying Your Battery: The Critical Importance of UN Hazard Categories

- Essentials of Car Battery Safety Management

- Conclusion:

- Learn More About Battery

What's the risk level of car batteries?

Car batteries are categorized into two primary hazard classes: Class 8 and Class 9. Lithium-ion and lithium batteries fall under Class 9 as miscellaneous hazards. Lead-acid batteries are in Class 8 – corrosive materials.But now the question arises, why are car batteries considered hazardous materials? What are the harmful substances within car batteries?What constitutes a harmful substance In layman's terms, we could define harmful substances as any materials that could pose a danger to health, safety, or the environment.Hazardous materials are divided into the following categories:- Explosives

- Flammable refrigerants

- Flammable gases

- Flammable solids

- Combustible (flammable or ignitable) liquids

- Organic peroxides

- Oxidizers

- Oxidizing refrigerants

- Self-combustible materials

- Unstable (reactive)

- Water-reactive materials

- Toxic substances

- Highly toxic substances

- Corrosive materials, etc.

Battery Disposal Alert: Navigating Hazardous Materials

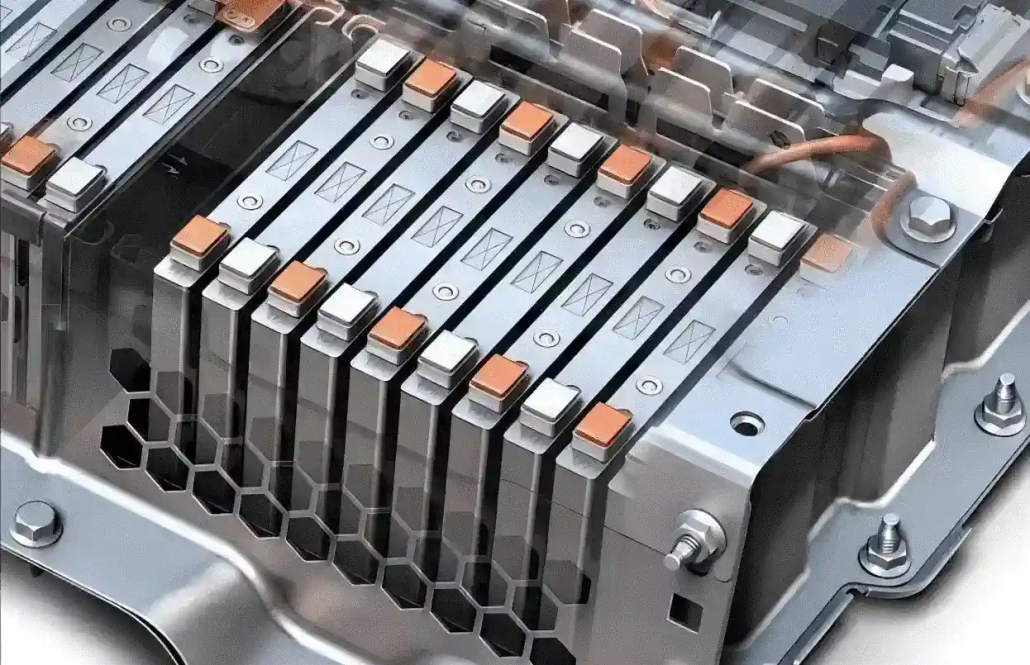

Car batteries are primarily lead-acid, wet cell, or Absorbent Glass Mat (AGM) batteries. Both types use alternating plates of lead and other materials, filled with an electrolyte solution containing sulfuric acid. Lead and sulfuric acid are hazardous substances that require disposal in proper facilities; they are too dangerous to be simply thrown in the trash.As mentioned at the beginning, lead-acid batteries are categorized as Class 8 hazardous materials because the sulfuric acid within can cause irreparable harm to human skin and is highly corrosive to steel. Hybrid and electric vehicles typically use lithium-ion batteries, which are classified as Class 9 hazardous materials.Class 9 hazardous materials include those that pose a transportation risk but don't easily fit into the previous 8 classes. In addition to Class 9 lithium-ion batteries, it also covers items like dry ice, some first aid kits, and fuel cell engines.In summary, batteries are classified as hazardous materials because they pose potential risks to health, safety, and the environment.Navigating the Hazards: Smart Shipping for Automotive Batteries

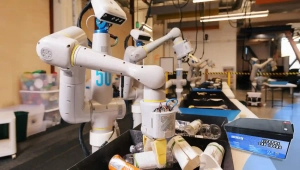

Automotive batteries are the powerhouses that keep our vehicles running, but when it comes to shipping them, they're a potential safety hazard. Classified as Class 9 hazardous materials, these batteries demand careful handling and adherence to strict regulations to ensure safe transport.Safe and Secure Packaging: A Must for Transport

The Pipeline and Hazardous Materials Safety Administration (PHMSA), an arm of the U.S. Department of Transportation (DOT), mandates that automotive batteries, especially those with lead acid, be packaged to prevent any risk of sparking or overheating during transport. This is non-negotiable; improper packaging could lead to severe penalties under U.S. law.International Standards for Global Shipping

Transporting these batteries beyond U.S. borders? They must meet the guidelines set by the International Civil Aviation Organization (ICAO), comply with the International Air Transport Association (IATA) Dangerous Goods Regulations, and adhere to the International Maritime Dangerous Goods (IMDG) Code. Different regions, like Canada and Europe, have their specific regulations which must be followed to the letter.Consult the Experts

For shippers unsure about the complex requirements, seeking advice from hazardous materials regulatory experts is essential. They provide the necessary clarity to ensure that you're not only compliant but also that your cargo and everyone involved in its transport remain safe.Key Considerations for Battery Shippers

When shipping automotive batteries, make sure:- They are packed to avoid any chance of generating heat.

- The packing prevents damage during transit, ensuring the batteries don't shift or activate accidentally.

- They're housed in strong outer packaging, safeguarded against short circuits, and insulated to withstand pressure changes and vibrations.

- The terminals are not exposed and are prevented from coming into contact with each other, avoiding potential short circuits.

Identifying Your Battery: The Critical Importance of UN Hazard Categories

Lithium-ion batteries are known as dangerous goods in category 9, UN3480. This type is the most common battery.Lithium-ion batteries contained in equipment, also category 9, UN3481, include common items like Apple iPhones.Lithium metal batteries and battery packs are considered hazardous, category 9, UN3090.Lithium metal batteries and battery packs contained in equipment, another set of hazardous materials, are in category 9, UN3091.Batteries with acidic solutions are dangerous goods, category 8, UN2794.Batteries with alkaline solutions are also dangerous goods, category 8, UN2795.Sealed batteries, potentially hazardous, fall under category 8, UN2800.Dry batteries containing solid potassium hydroxide are dangerous goods, category 8, UN3028. They are alkaline and must be kept separate from acids.Nickel-metal hydride batteries are categorized under 9, UN3496.Fuel cells vary based on the electrolyte and hazardous components inside; they can be in category 3, UN3473, 4.3 class, UN3476, 8 class, UN3477, or 2.1 class, UN3478 and UN3479.Vehicles or engines powered by fuel cells are considered dangerous, category 9, UN3166.Sodium batteries, dangerous goods, are in category 4.3, UN3292.Battery-powered vehicles or equipment are listed as dangerous goods, UN3171. This includes electric cars, lawnmowers, wheelchairs, etc.Essentials of Car Battery Safety Management

Handling car batteries demands stringent safety protocols to prevent accidents and environmental harm. Here's a distilled guide to car battery safety:- Wear Proper PPE: Always use safety goggles, gloves, and appropriate clothing to shield yourself from acid splashes and chemicals.

- Ventilated Work Areas: Operate in well-ventilated spaces to disperse any harmful gases emitted during battery charging or maintenance.

- Power Off Vehicles: Turn off the engine, headlights, and any electrical accessories before working on the battery to avoid sparks and electrical hazards.

- Disconnect Negative First: When removing the battery, always detach the negative (black) terminal first to minimize the risk of short-circuiting and sparks.

- Use Insulated Tools: Employ insulated tools and wrenches specifically designed for battery tasks to prevent accidental electrical contact.

- Inspect for Damage: Regularly check the battery for visible damage or leaks. If damage is detected, do not handle the battery and seek professional assistance.

- No Smoking or Flames: Refrain from smoking or using open flames near the battery due to the potential flammability of hydrogen gas emitted during charging.

- Handle with Care: Lift batteries carefully, using your legs instead of your back, to avoid strains or injuries.

- Charge in Safe Location: Charge batteries using chargers intended for automotive batteries, and place them on a stable, non-flammable surface.

- Follow Manufacturer Guidelines: Adhere strictly to the manufacturer's charging and maintenance instructions.

- Avoid Overcharging: Prevent overcharging the battery to avoid gas buildup and potential explosion.

- Dispose of Old Batteries Properly: Recycle old batteries at designated centers or automotive shops, as they contain harmful substances.

- Emergency Eyewash and Showers: Have emergency eyewash stations and showers available when working with lead-acid batteries to counteract acid exposure.