Manufacturer vs. Distributor: What is the Difference in Battery Industry?

Table of Contents

Manufacturer vs. Distributor: Definition of a Battery Manufacturer

A manufacturer is a company or individual that makes goods from raw materials, using various machines, tools, and labor. In the battery industry, a manufacturer plays a crucial role in creating products like lithium batteries, lead-acid batteries, and more. They take raw materials, such as lithium, lead, and other chemicals, and transform them into finished products that can be used in various applications, from small electronics to large industrial machines.Manufacturers are responsible for designing, developing, and producing these battery products. They often have large factories where they employ engineers, technicians, and production workers to ensure the batteries are made to precise specifications. The process involves several stages, including research and development, where new battery technologies are created and tested, and production, where these designs are brought to life.An excellent example of a battery manufacturer is Farasis Energy, which was founded in 2002. They specialize in making lithium-ion batteries for electric vehicles and energy storage systems. Farasis Energy is known for its advanced research and development capabilities, which allow them to produce high-quality, reliable batteries that meet the demands of modern technology.In addition to creating the batteries, manufacturers are also responsible for ensuring the quality and safety of their products. This involves rigorous testing and quality control measures throughout the production process. For instance, each battery must undergo multiple tests to ensure it meets safety standards and performs as expected. This can include testing for durability, efficiency, and safety under various conditions.Manufacturers also play a significant role in innovation within the battery industry. They invest heavily in research and development to create new and improved battery technologies. This could mean developing batteries that last longer, charge faster, or are more environmentally friendly. By constantly pushing the boundaries of what batteries can do, manufacturers help drive the industry forward and meet the evolving needs of consumers and businesses.Another important aspect of being a battery manufacturer is managing the supply chain. This involves sourcing raw materials, managing relationships with suppliers, and ensuring that all components are delivered on time and meet quality standards. Manufacturers must also handle logistics, including the storage and transportation of finished products to distributors or directly to consumers.A well-known case in the battery manufacturing industry is Tesla, which not only makes electric cars but also produces the batteries that power them. Tesla's Gigafactory, located in Nevada, is one of the largest battery manufacturing plants in the world. It exemplifies how a manufacturer can scale production to meet high demand while maintaining control over the quality and innovation of its products.Manufacturer vs. Distributor: Definition of a Battery Distributor

A distributor is a company that buys products from manufacturers and sells them to retailers, wholesalers, or directly to consumers. In the battery industry, a distributor plays a crucial role in the manufacturing and distribution process by ensuring that batteries produced by manufacturers reach the market efficiently.Distributors purchase large quantities of batteries from manufacturers and store them in warehouses. They manage the logistics of getting these batteries to retailers or end-users. This includes handling transportation, warehousing, and inventory management. By taking care of these tasks, distributors allow manufacturers to focus on producing high-quality batteries without worrying about the complexities of distribution.For example, a well-known battery distributor is Interstate Batteries. They distribute batteries for various uses, including automotive, commercial, and marine applications. Interstate Batteries operates a vast network of warehouses and delivery routes to ensure that their products are available where and when they are needed.Distributors often offer additional services like marketing and technical support to help retailers sell the batteries. They might provide training for retail staff, promotional materials, and after-sales support. This added value helps retailers better serve their customers and can lead to increased sales for both the distributor and the manufacturer.In summary, a distributor is a vital link between battery manufacturers and the market. They handle the logistics of getting batteries from the factory to the store shelves, ensuring that the supply chain runs smoothly. Interstate Batteries is a prime example of how effective distribution can enhance the availability and success of battery products.Battery Manufacturer vs Distributor:Key Differences

Understanding the key differences between a manufacturer vs distributor in the battery industry is crucial for businesses and consumers alike. Both roles are vital, but their responsibilities and how they interact within the supply chain differ significantly. This section will explore these differences and their impacts on the manufacturing and distribution of batteries.

Comparison of Responsibilities

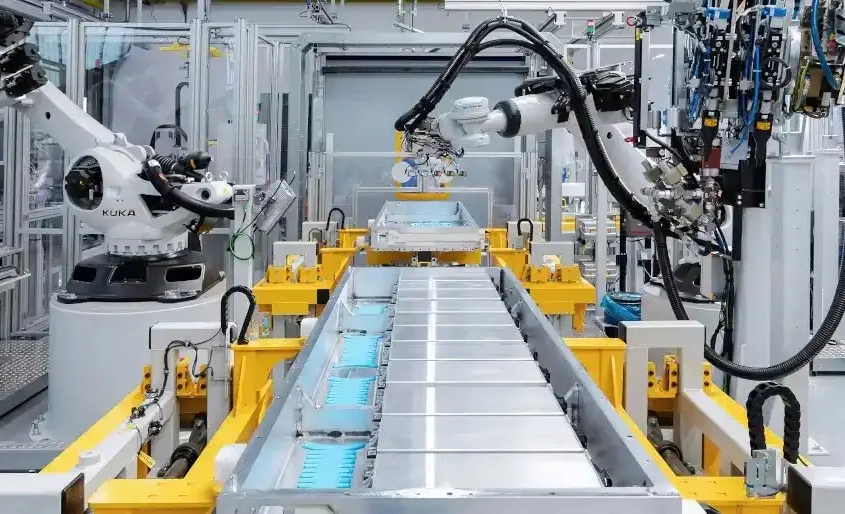

Manufacturers are responsible for creating battery products from raw materials. They design, develop, and produce batteries, ensuring each product meets specific quality and safety standards. The primary focus of manufacturers is on innovation and efficiency in production. They employ engineers, researchers, and production staff to continuously improve battery technology and production processes.For example, MANLY Battery, a leading battery manufacturer in China, exemplifies the role of a manufacturer in the industry. Established over 13 years ago, MANLY Battery operates state-of-the-art facilities in Shenzhen, Dongguan, and Huizhou. Their daily production capacity is impressive, churning out 6MWh of battery cells and assembling over 3,000 batteries every day. MANLY specializes in a wide range of lithium-ion and LiFePO4 batteries, catering to various applications such as solar energy storage, industrial energy storage, advanced robotics, and UPS systems. Their commitment to quality is reflected in their global certifications like UN38.3, IEC62133, UL, and CE, and they offer a robust 10-year warranty on their products.On the other hand, distributors purchase finished products from manufacturers and sell them to retailers or directly to consumers. Their main responsibility is to manage the logistics of moving batteries from the manufacturer to the market. This includes warehousing, transportation, and inventory management. Distributors often handle customer service and after-sales support, providing a vital link between manufacturers and end-users.Here's a simple comparison table to illustrate the differences:| Aspect | Manufacturer | Distributor |

|---|---|---|

| Main Role | Producing batteries from raw materials | Selling and distributing finished batteries |

| Key Responsibilities | Design, production, quality control | Warehousing, logistics, customer service |

| Focus | Innovation, efficiency, product development | Market reach, inventory management, sales support |

| Example | MANLY Battery producing various lithium-ion batteries | Interstate Batteries distributing to various sectors |