LiFePO4 vs Lead Acid: Best Battery Choice for Your Business in 2024

Table of Contents

- LiFePO4 vs Lead Acid: Best Battery Choice for Your Business in 2024

LiFePO4 vs Lead Acid: Industry Adoption and Benefits

Market Trends for LiFePO4 Battery

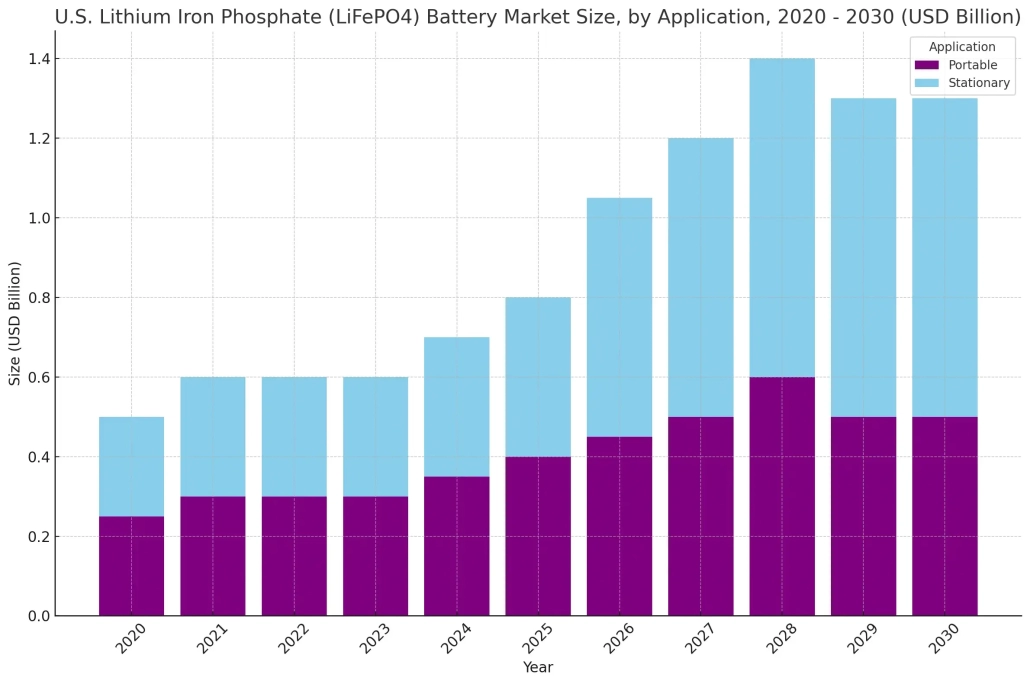

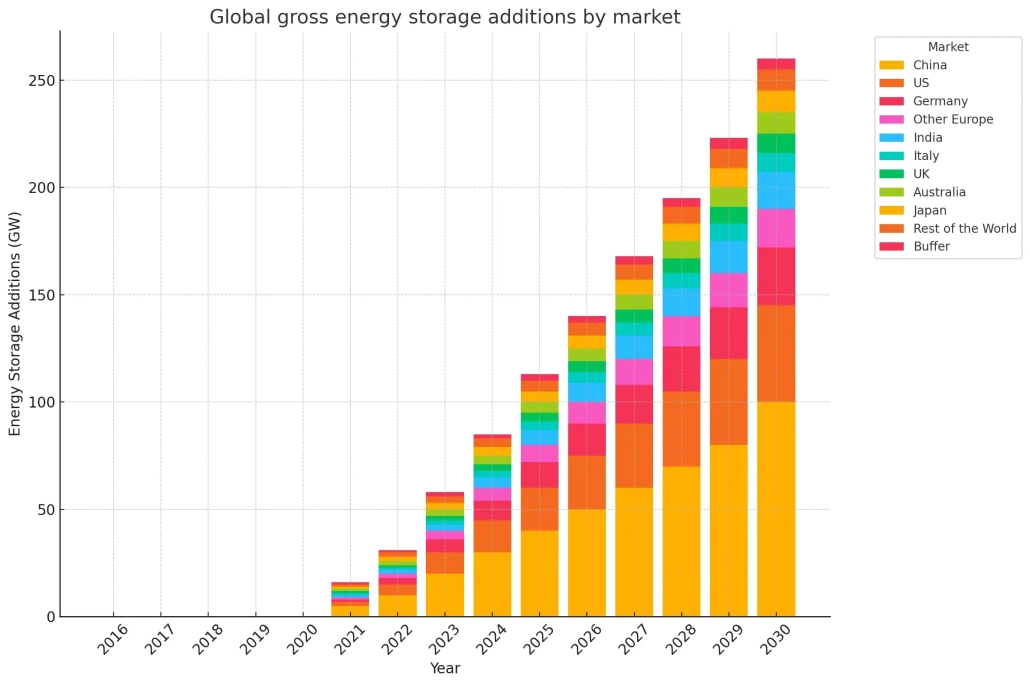

The market for LiFePO4 battery technology is experiencing rapid growth due to its numerous advantages over traditional lead acid battery systems. In 2023, the global LiFePO4 battery market was valued at $8.25 billion and is projected to grow at a compound annual growth rate (CAGR) of 10.5% from 2024 to 2030. This growth is fueled by increasing environmental awareness, rising demand for electric vehicles (EVs), and the expanding use of battery storage systems. Key regions driving this market include Asia-Pacific, North America, and Europe, each contributing significantly due to different factors such as technological advancements, regulatory support, and growing industrial applications.

Forklift Industry

The forklift industry is a notable example where LiFePO4 battery technology is gaining ground. According to market research, the global forklift battery market is expected to reach $25.67 billion by 2024, with a compound annual growth rate (CAGR) of 6.6% from 2024 to 2034. The transition from lead acid battery to LiFePO4 battery systems is primarily due to the latter's higher energy efficiency and longer lifespan.Case Study: Vedanta AluminumIn June 2022, Vedanta Aluminum, India's leading aluminum producer, implemented the country's largest fleet of electric forklifts powered by lithium-ion batteries. This transition has significantly enhanced operational efficiency and reduced maintenance costs, demonstrating the practical benefits of LiFePO4 battery technology in heavy industrial applications.Several companies are investing heavily in the development and manufacturing of LiFePO4 battery technology. For instance, in May 2023, Johnson Controls announced a $100 million investment to expand its battery manufacturing capacity in the United States. This investment aims to meet the growing demand for electric forklift batteries, highlighting the increasing preference for LiFePO4 battery systems. Similarly, EnerSys partnered with Toyota Industries in April 2023 to develop new battery technologies for electric forklifts, focusing on creating batteries with longer lifespans and faster charging times.Electric Vehicle Industry

The electric vehicle (EV) industry is also seeing substantial adoption of LiFePO4 battery technology. The increased demand for hybrid and electric vehicles, along with greater environmental awareness, is driving this growth. In Europe, for instance, the growing popularity of electric vehicles is boosting the demand for LiFePO4 battery systems, supported by favorable government policies and regulations.In the electric vehicle sector, LiFePO4 battery technology offers several advantages, including higher energy density, faster charging times, and a longer lifespan. These benefits make them an ideal choice for manufacturers aiming to produce efficient and reliable EVs. The market for electric vehicles is expected to continue its rapid growth, further driving the demand for LiFePO4 battery technology.Energy Storage Systems

Energy storage systems (ESS) are another critical area where LiFePO4 battery technology is making significant inroads. The global energy storage market nearly doubled in size in 2023, largely driven by the reduced cost of storage systems, especially in China, where turnkey energy storage system costs dropped by 43% year-over-year. The cost-effectiveness and superior performance of LiFePO4 battery systems are key factors in their increased adoption for energy storage applications.In the United States, the energy storage market is expanding rapidly, supported by state government targets and utility procurements. This growth is further accelerated by the advantages of LiFePO4 battery technology, such as longer lifespan and enhanced safety, making it a preferred choice for large-scale energy storage projects. The adoption of LiFePO4 battery systems in energy storage solutions helps in managing peak loads, integrating renewable energy sources, and ensuring a reliable power supply.

LiFePO4 vs Lead Acid: Cost Efficiency for Enterprises

Initial Costs

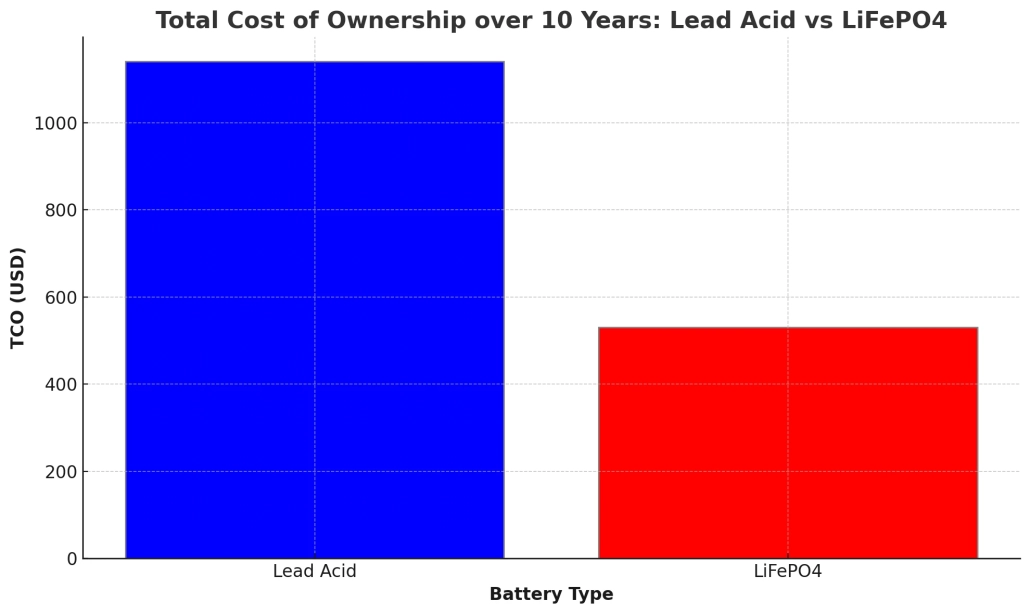

When comparing the costs of LiFePO4 battery and lead acid battery systems, the initial purchase price is an important factor. A typical 12V 100Ah lead acid battery costs around $90, while a comparable LiFePO4 battery is priced at about $190. Although the upfront cost of a LiFePO4 battery is higher, it's essential to consider the long-term financial benefits.Lifespan and Cycle Cost

The lifespan of a battery significantly impacts its overall cost efficiency. Lead acid batteries usually last for about 300 charge cycles, maintaining 60% of their capacity. In contrast, LiFePO4 batteries can handle up to 2000 cycles while still retaining 60% capacity. When we break down the cost per cycle, a lead acid battery costs approximately $0.30 per cycle ($90/300 cycles). On the other hand, a LiFePO4 battery costs about $0.095 per cycle ($190/2000 cycles). This lower per-cycle cost demonstrates the superior cost efficiency of LiFePO4 batteries over their lifespan.Maintenance Costs

Another critical aspect to consider is the maintenance cost. Lead acid batteries require regular maintenance, including watering, cleaning terminals, and performing equalization charges. This maintenance can cost around $50-$100 per year. Conversely, LiFePO4 batteries require minimal maintenance, with annual costs estimated at $10-$20 primarily for occasional cleaning. This significant reduction in maintenance needs further enhances the cost efficiency of LiFePO4 batteries.Case Study:

Golf Cart BatteriesTo illustrate these points, let's look at the cost comparison for golf cart batteries. A set of lead acid batteries for a golf cart typically costs between $800 and $1,500, while a set of LiFePO4 batteries costs around $2,000. Although the initial cost of LiFePO4 batteries is higher, they offer a longer lifespan (8-10 years compared to 3-4 years for lead acid batteries) and significantly lower maintenance costs. This results in long-term savings and reduced hassle for businesses that rely on golf carts.Forklift Battery CostsForklift batteries provide another excellent comparison. Lead acid forklift batteries cost between $2,000 and $6,000, whereas LiFePO4 forklift batteries range from $17,000 to $20,000. Despite the higher initial investment, LiFePO4 batteries offer longer service life and minimal maintenance, translating to lower total ownership costs over time. For instance, the need for regular watering, cooling periods, and vent inspections with lead acid batteries increases downtime and labor costs. In contrast, LiFePO4 batteries eliminate these requirements, allowing for more efficient operations.Total Cost of Ownership

The total cost of ownership (TCO) is a crucial metric for enterprises evaluating battery options. While lead acid battery systems might seem cheaper initially, their shorter lifespan, higher maintenance costs, and lower efficiency lead to higher long-term expenses. LiFePO4 battery systems, despite a higher initial cost, prove more economical over time due to their durability, low maintenance, and superior performance.