25.6V 30Ah AGV Battery Design Scheme

Quote: (Keywords: Automatic Guided Vehicle Battery/AGV Battery) AGV refers to a transport vehicle equipped with electromagnetic or optical automatic guidance devices that can travel along a prescribed guidance path, with safety protection and various transfer functions, and a transport vehicle that does not require a driver in industrial applications. The main function of the battery is to provide power energy for the AGV. It has long cycles of charge and discharge, low self-discharge rate, long service life, strong deep discharge capability, high charging efficiency, strong power, strong shock resistance, low maintenance or no maintenance, etc. The advantages. Advantages: small size, light weight, long life, high replacement efficiency, deep charge and discharge, intelligent management, and provide reliable and high-quality power energy for your system.

I. Battery design requirements for 25.6V 30Ah AGV

1) Cell shape requirements: use square aluminum shell lithium iron phosphate power battery (LP32700-8S5P/30Ah/25.6V).

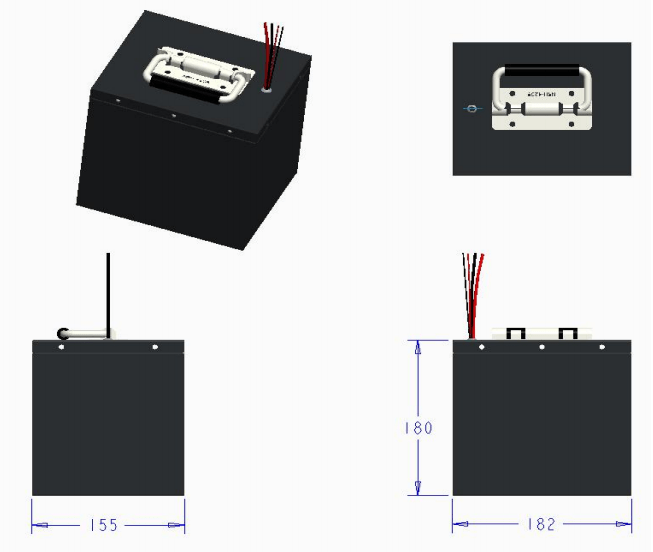

2) Structural design requirements: exquisite appearance, and the overall battery meets the requirements of waterproof, dustproof and shockproof. Battery space, 155*182*195mm

3) Circuit design requirements: 25.6V/30Ah, normal charging current 15A, normal working current 14A, instantaneous maximum working current 27A; conventional protection function, with equalization circuit, can effectively make up for the difference between the battery cells during battery use Difference, maximize battery life; working temperature -20℃-60℃

II. 25.6V 30Ah AGV Battery Design Scheme

1) Sheet metal powder-sprayed shell: The sheet metal shell is exquisitely designed according to customer requirements, and the surface is sprayed with sub-black powder, which effectively protects the shell from oxidation and discoloration due to environmental influences. The sealing strip is designed to meet the requirements of waterproof, dustproof, and shockproof. Two outlet holes for charging and discharging and communication protocol are reserved on the shell. The thermal insulation layer uses a thermal insulation material with a thickness of about 5mm. The outer box adopts a handle design, which is convenient for temporary transportation and use; the upper cover and the panel are flexibly disassembled, which is convenient for battery maintenance;

2) Battery Management System (BMS):

BMS design: The solution uses a high-precision detection BMS as the battery information collection unit, which has overcharge, over-discharge, overcurrent, short circuit, high and low-temperature protection, and can balance the voltage and current of a single cell.

3) Overcurrent protection chip (PTC): Mainly designed for secondary protection function. The PTC recoverable fuse has the dual function of overcurrent protection and automatic recovery. The PTC in the battery product can prevent the high-temperature discharge of the battery and the occurrence of unsafe high currents.

4) Communication protocol: RS485

5) LFP32700-8S5P/30Ah/25.6V battery pack