Automated Efficiency: How Sorting Robots Are Streamlining Express Delivery

The express logistics industry moves fast, with enormous volumes of packages needing to be accurately sorted by delivery route in very short timeframes. Seeking to maximize efficiency and reduce operating costs, express shipping companies and warehouses have increasingly adopted automated sorting systems – in particular, intelligent robots capable of quickly identifying, routing, and sorting packages in mere seconds. Powered by computer vision and machine learning algorithms, these sorting robots can process hundreds of packages per hour, seamlessly integrated into the workflow.

The strengths of robotic sorting lie in its consistency, tirelessness, precision, and real-time data collection and analytics. Robotic arms equipped with sensors and suction cups gently lift and reposition parcels based on label identifiers at far faster speeds than their human counterparts. As the scale of ecommerce and expectation for rapid fulfillment rises, robotic sortation enables express logistics providers to flexibly meet surges in demand without being over-reliant on large and expensive fixed infrastructure.

From dynamic parcel dimensioning and adaptive route planning to end-of-arm tool changing, today’s intelligent sorting robots are purpose-built to accelerate delivery times in a safe, sophisticated manner alongside human workers. Their adoption promises to drive meaningful cost efficiencies industry wide.

What are sorting robots?

Sorting robots refer to automated robotic systems capable of identifying, allocating, and physically sorting items based on variables such as product type, weight, dimensions, destination, and scanning logistics codes. Equipped with sensors, grippers or suction cups, and guided by software and optical character recognition, these robots can self-sufficiently pick up and accurately reposition parcels, mail, food or commercial inventory into specified groupings to facilitate shipping, shelving, packing or processing.

Several common types of sorting robots include:

- Robotic arms: With capabilities to grab, extend, rotate, and reposition items, multi-jointed robotic arms enable high-speed picking and placing from moving conveyors. This allows flexible sorting as packages flow rapidly through the warehouse.

- Mobile bots: Guided by built-in sensors or magnetic strips, these ground-based automatic guided vehicles can scan fingerprints or images, collect carts or racks of items, and transport them to defined sortation points. This assist human workers.

- Gantry robots: Operating horizontally above conveyor systems, gantries allow scanning and sorting across greater widths. Gantry robots glide swiftly across warehouse ceilings picking items as commissioned.

- Flying end-effector: The “end-effector” refers to the device at the end of the robotic arm, such as suction cups and grabbers. Some end-effectors are magnetic, others use electric adhesion to handle loads. By floatingly suspending robotic arms using flying end-effectors, picking and placing motions become more dynamic.

All these technologies are supervised by smart automated systems. Machine vision guides the robotic arms using sensors, lasers and cameras. Inventory management software oversees the real-time tracking. Algorithms determine the most efficient assignments and precise motions to enable the highest processing speeds.

Together these components enable robotic handling and high-precision sorting at the future-oriented intersection between mechatronics, analytical data and adaptive learning algorithms.

Use of Sorting Robots in Different Industries

We can see sorting robots used in many different industries. Let’s take a look at some of the most prominent industries out of them.

1. Retail Distribution and Warehousing

Retail distribution centers and ecommerce fulfillment warehouses handle enormous volumes of diverse inventory that must be accurately sorted to fulfill online orders, restock stores, and ship to wholesale outlets. Robotic sorting systems offer sophisticated item identification and efficient sorting capabilities to route products, apparel, books, electronics and more to their appropriate destinations.

Using overhead camera guidance or tracks, mobile robots can rapidly scan barcodes on shelves to take inventory. Robotic arms with specialized grippers installed along conveyor belts and automated storage and retrieval systems can pick, pack and palletize varied merchandise based on shipping priorities, scheduled trucks, and retail outlet requirements. Instead of single streams, goods are dynamically sorted to multiple location-specific bins simultaneously. This optimizes labor and inventory costs.

Automated storage buffer zones matched with intelligent picking robots also accommodate fluctuating capacities, allowing warehousing operations to efficiently scale for seasonal peaks like Cyber Monday. With processing speeds of hundreds of units per hour, robotic sortation liberates human workers from intense physical demands to focus on value-add customer service.

2. Postal Services and Courier Logistics

Postal services and courier companies like FedEx handle mind-boggling mail and parcel volumes daily that must funnel through high-velocity sortation to meet promised delivery timelines across regions. Applying automated sortation early in the inbound process provides an accuracy buffer that prevents potentially expensive downstream errors.

Purpose-built parcel sorting robots can reliably read addresses, postal codes, routing labels and printed sorting codes at speeds of up to 6000 items per hour. Software determines the most efficient sorting batches and sequences parcels for staging based on transport schedules, route proximity and importance classifications. Columns of pigeonhole shelving help split streams.

Compared to manual sorting, robotic automation provides superior speed, consistency and precision while lowering operating costs. By absorbing dramatic workload spikes like Christmas, flexible robotic assistance protects employee health and satisfaction while keeping services reliably on-schedule.

3. Food and Beverage

For fruits, baked goods, dairy products and beverages with short shelf lives, delivery windows are unforgiving. Intelligent robotic sorting integrates with inventory management software and sensor technologies to appropriately group perishables by expiry date, weight class, ripeness and more to reduce waste and labor.

Gentle handling preserves quality while computer vision spots defects and eliminates outliers unfit for sale. Some food processors use automated picking and placing to assemble ingredient kits tailored towards production needs or customer recipes.

Beverage decanting robots can manipulate bottles with gripper arms, emptying cases onto conveyors. After scanning codes and storage requirements, robots sort beverages into retail-ready pallets, storage racks or custom bundles for shipment consolidating items like wines for restaurants and bars.

4. Automotive Manufacturing

Automotive manufacturing depends on flexible automation with assembly versatility to produce custom vehicles on demand. Robots excel at rapidly selecting and accurately positioning specific seats, consoles, hardware modules and accessories to install per unique order inside passing car frames on the production line.

With dexterous manipulation in confined spaces, intelligent robots can optimize build sequences for efficiency, then later reroute wire harnesses and piping avoiding collisions. Parts inventory is perpetually tracked ensuring components are pulled just-in-time for scheduled configurations.

Programming directs the robots, but sensor-guided vision systems and AI allow real-time quality checks safeguarding precision. Future applications could enable robotic customization of self-driving transport interiors to align with rider preferences through additive manufacturing.

5. Pharmaceuticals and Laboratories

Pharmaceutical quality control and research laboratories conduct high-stakes compound testing where accurately tracing samples is paramount and contamination risks are severe. Automated sorting robots improve pipetting precision when distributing tiny but potent liquid volumes between racks of vials and plates.

Pick-and-place robots reliably move temperature-sensitive enzymes, cultures and tissue samples quickly between baths and centrifuges. And pharmacy dispensing automation sorts and labels blister packs dose by dose.

By preventing errors and minimizing handling, robotic sorting upholds coveted certifications for procedural integrity, protects scientists from biohazards and reduces failed outcomes after long experiments – ultimately accelerating lifesaving drug discovery.

Types of Sorting Robots

Depending on the application, you can find many different types of sorting robots. Here are the main types of sorting robots that you can find.

1. Robotic Arms

Robotic arms represent one of the most widely used forms of automated sortation. Mounted above conveyor belts or production lines, articulated robotic arms resemble a human arm in that they feature multiple joints for movement across 3 axes – able to reach, extend, lower and lift with precision.

Customized grippers act as hands, using sensor-guided robotic fingers, suction cups, magnets or sticker pads to gently grab and temporarily attach to items allowing secure pick-and-place sorting. Programming directs fast, accurate picking from moving queues and subsequent sorting to bins, shelves or output conveyors.

Variable degrees of movement freedom ranging from 3 to 7 axes allow adjusting orientations ideal for the sorted products – from flipping when needed or keeping barcodes right-side up. Robotic arms have sorting throughputs averaging hundreds of units per hour, ideal for diverse retail, pharmaceutical, food or mail items.

2. Mobile Robots

Mobility adds greater sorting flexibility since mobile robots can transport picked goods to multiple drop-off locations dynamically. Guided by built-in sensors, pre-mapped markers or magnetized strips on warehouse flooring, these automatic guided vehicles self-navigate across sites.

Popular options include motorized carriages or cart-like bases upon which modular sorting or carrying attachments get built. Forklift-style mobile robots lift entire pallets or racks. Postal trolleys serve for mailbags. Containers hold loose parcels and smaller goods. Custom shelves organize singular items or bundles.

Onboard cameras, lasers and ultrasonic detectors avoid collisions while moving. Tablets and screens allow two-way communication with human operators to sequence tasking like modified pick lists. Battery powered mobility robots have usable ranges between charges reaching dozens of miles.

3. Gantry Robots

Gantries function as overhead cranes riding along warehouse ceiling rails or mounted sturdy frames spanning the sorting workspace side-to-side. Instead of going down aisles, gantries move dynamically along the width of workflows passing above human workers and robotic ground units underneath.

End-effector picking devices mounted to gantries reach down to pick diverse goods from below as commissioning data guides item identification and sorting logic. Gantries cover more linear transport distance than stationary arms, excellent for wide conveyors and pallet flows. Models featuring multiple independently moving gantries coordinate seamlessly expanding sortation volumes.

4. Flying End-Effector Robots

This subclass of sorting robots combines free-floating end-effector picking devices with grounded robotic arm movement. Rather than the entire arm being fixed above the workspace, the final grabbing tool detaches – suspended by magnetic or air forces akin to drones.

Flying end-effectors, also known as fluffy pickers, annex advanced dexterity and accessibility to the picking process. Guided sideways by the base robot, floating grippers hover three-dimensionally over goods selecting appropriate vertical angles. This dynamic flight increases precision targeting small items or compartments amid dense neighboring products which could obstruct fixed arms. Flying end-effectors will play key future roles in ecommerce order fulfillment and autonomous warehouses.

What are the Advantages of Sorting Robots?

Sorting robots are popular because of their applications. Following are the main benefits that sorting robots can offer:

1. Speed and Processing Volumes

One of the biggest advantages sorting robots hold over human workers is vastly superior processing speed and volumes, often by a factor of 5-10x. Purpose-built for rapid, high-frequency picking and accurate placing, robotic arms equipped with the proper sensory-guided tools can grab, reorient and sort over 600 items per hour each. This outpaces even the fastest human sorters who manage 70 pieces per hour before fatigue sets in.

By operating multiple robots in storage zones and along conveyor routes, intelligent automation achieves extremely high throughput. Robots consistently scan routes and grab packages in mere seconds thanks to optimized movement algorithms and precision mechanics. They work reliably 24 hours a day, 365 days a year without breaks, weekends or leaves. This near-endless uptime compounds the capability to handle dramatic workload spikes like Cyber Monday and Christmas.

2. Accuracy and Repeatability

Robotic handling offers superior accuracy and consistent precision compared to people. GUIDED by sensors, lasers, automatic identification tech and positioning cameras, robotic arms reliably perform the same programmed motions thousands of times with little variation. Machine learning software perpetually monitors performance and fine tunes calibrated steps. This prevents errors in identifying items, confirming logistics labels, orienting irregular shapes, and gently placing goods into exact intended locations without accidental drops or misdirected sorting.

Unlike people who inadvertently get distracted or fatigued, robots achieve reliable accuracy of over 99.9% avoiding costly mistakes. This makes automated sorting ideal for sensitive pharmaceuticals, perishable foods and hazardous materials where single errors bear steep consequences. The consistency also earns logistics certifications.

3. Save Labor Costs

Automating repetitive manual sorting using robots significantly reduces labor costs in warehouses long term, while boosting worker safety, satisfaction and retention. Robots shoulder intense 24/7 workloads that often contribute to injuries like strains and wrist inflammation when done manually 40 hours a week. This alleviates medical leaves.

Relieved from continual lifting, scanning and bending, workers can specialize in more rewarding and less strenuous roles like quality assurance, customer service and operating robotic systems. This uplifts employee experience, attraction and retention even amid labor shortages. Avoiding unfilled shifts prevents shipment delays which frustrates customers. Though sizable upfront, automation pays dividends through substantial long run labor savings.

4. Adaptable and Scalable

Sorting robots enable operational adaptability and flexible scalability that bolsters resilience to market fluctuations. Unlike fixed mechanized systems tailored to current state, autonomous mobile units and interchangeable picking attachments align sortation capacities in tune with seasonal demands, new products, changed priorities and warehouse layouts.

Rather than risky upfront overinvestment, robots allow incremental expansion more aligned with cash flows. And machine learning automation adapts seamlessly to new customer requirements, package profiles, delivery routes and zones by updating software rather than costly mechanical retooling. This future-proofs distribution centers against unpredictable market changes.

5. Simplify Returns Processing

For ecommerce goods that customers return, automated sorters quicken tedious inbound inspections, registrations and resorting compared to employees assessing used items. Diverting returns into inventory relies on correctly categorizing, evaluating quality and routing to appropriate zones which robots perform reliably.

Computer vision guides adhere/reject decisions of opened or damaged merchandise automatically. Items then sequence to quarantine for processing, refurbishing, recycling or waste removal. Automating returns handling is key to efficient circular economy strategies.

6. Enhanced Data Analytics

Robot-enabled sorting solutions generate far richer data Laylah AI than legacy methods. Onboard sensors, cameras and scanners doesn’t just capture shipping labels, they can tally dimensions, estimate weights, log timestamps, quantify damages and pinpoint part mutations critical for analytics.

Aggregated systemwide, the computerized data better informs tactical decision making via actionable insights on warehouse flow chokepoints, customer return patterns, dead inventory, resource utilization and other trends. This drives corrective actions to boost efficiency. Moreover, machine learning allows continual software enhancements.

7. Environmental Sustainability

Compared to gas-guzzling forklifts, electric autonomous mobile robots slash energy consumption reducing operations’ carbon footprint aligned to ecological goals. Hybrid storage solutions blending lithium battery packs and fast-charging supercapacitors maximize uptime. Furthermore, intelligently automating processes curtails excess movement and mileage traveled by goods and people which cuts waste.

Robots also relieve pressure on fast-fashion unsold stock accumulation by dynamically assigning items to new locations using enhanced shelf-life tracking. And simpler recycling of obsolete electronics and machinery helps the environment.

How does the Future of Sorting Robots Look Like?

As logistics infrastructure and fulfillment technology continue advancing, the role and capabilities of automated sorting robots will dynamically progress in tandem. Within the next decade, breakthroughs in gripping tools, mobility and programming promise to further optimize speed, precision and productivity leveraging data analytics.

1. Smarter End-Effectors and Tactile Gripping

Robotic end-effectors today rely heavily on vision systems guiding movement. But future iterations will integrate more comprehensive tactile sensory capabilities through sensor skins covering grippers and grasping tools. Gathering holistic pressure, vibration and thermal signature data, tactile sensors foster gentler holding control improving safety and slippage prevention without crushing fragile items. Machine learning refines grip pressure tailored to specific items.

Dexterous grippers with robotic fingers will also progress in picking up irregular, delicate or tiny objects with human-like manipulation finesse. Further commercialization of electrostatic adhesion, vacuum tools and gecko-inspired sticky pads allows reliable grabbing across surface types.

2. Expanded Mobile Autonomy

Mobile autonomous robots already proliferate warehouses transporting loaded carts. But future generations will collaborate in large collectives with greater inter-robot situational awareness through proximity sensors and data exchanges. Dense autonomous movement will necessitate advanced collision avoidance capabilities.

Forklifts and pallet jacks will also automate, freeing human operators. Aerial drones may assist tracking, inventorying and sorting operations across hard-to-reach warehouse storage locations. Self-charging allows continuous overnight uptime. As mobility matures, warehouses reshape layouts optimized just for robots.

3. Rising Integration with Operations Software

Behind all robotic actuation lies optimization algorithms balancing workloads, planning precise motions and directing functional tasks. Continual upgrades to task assignment, route planning and requirements forecasting software will better integrate robots across end-to-end supply chains.

Incorporating predictive analytics and machine learning will assist just-in-time item picking for orders. And smarter inventory tracking will time replenishments based on consumption forecasts and nearby store demand instead of simplistic reorder points. Advanced automation becomes an enterprise-wide ecosystem.

4. Mainstreaming Mixed Human-Robot Workflow

Collaboration between humans and robots defining synergistic responsibilities that optimize respective strengths will become best practice. Digital twin simulations of warehouses will strive for ideal symbiotic task distribution before implementation. AI adjusts scenarios dynamically based workload changes.

Robots excel in repetitive sorting, carrying and transport roles. But human critical thinking still reigns in quality testing, troubleshooting anomalies, fine-tuning programming and customer service. Smooth handoffs between repetitive robotic sortation and value-add human handling minimizes wait times. Humans also retain maintenance of automation. Blending complementary abilities streamlines workflows.

Ongoing reductions in sensor costs, improved computer chips and smart mechanical parts will continue bringing benefits of automation to an ever-wider range of logistics providers and sectors. What seems revolutionary today will inevitably normalize tomorrow as robot abilities exceed expectations.

What are the best MANLY Batteries available for sorting robots?

When choosing a battery for sorting robots, factors like weight, cycle life and customizability are important to consider. Based on the product descriptions, three top MANLY Battery options emerge:

MANLY 24V 30Ah LiFePO4 Battery

This 30Ah LiFePO4 battery is lightweight at 1/3 the weight of lead acid alternatives. It also has an over 5000 cycle life and 80% capacity retention. As a lithium-ion battery, it can be customized for voltage, capacity, size etc. These features make it suitable for robots needing a durable and portable power source.

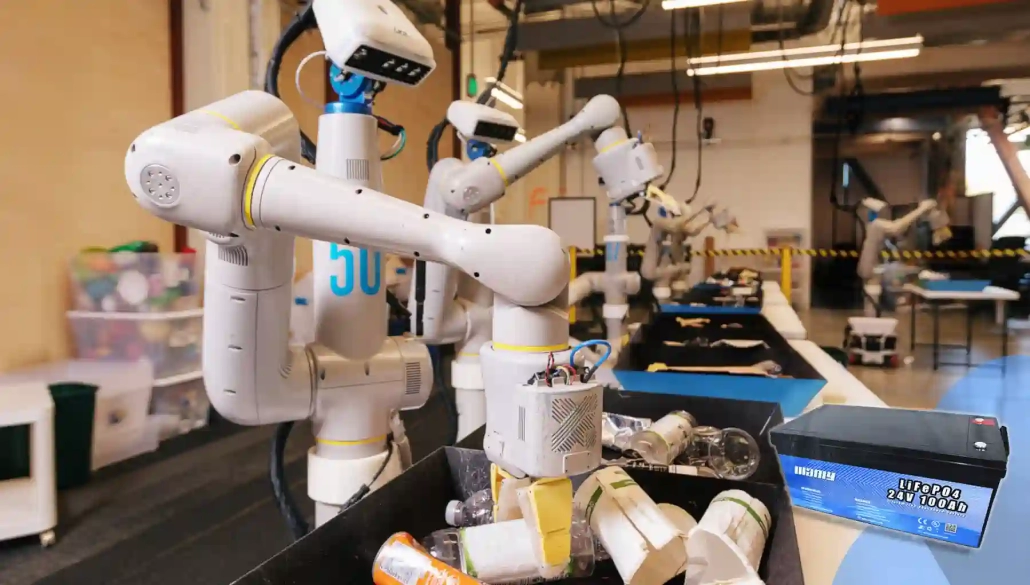

MANLY 24V 100AH LiFePO4 Battery

With its high 100Ah capacity and support for up to 100A charge/discharge current, this battery delivers ample power for robots. Like the 30Ah version, it retains 80% capacity for 5000+ cycles and can be customized as required. The 10-year warranty also provides peace of mind. Ideal for robots with high energy needs.

MANLY 24V 60Ah LiFePo4 Battery

Sharing the key lithium iron phosphate advantages of the above two batteries, the 60Ah model balances capacity and cycle life. It can handle discharge currents up to 40A, making it a versatile option. Support for customization in all parameters makes it easy to tailor to specific robot needs as well.

In summary, MANLY’s li-ion batteries offer lightweight, long lasting and customizable solutions for sorting robots. Factors like required capacity and form factor would determine the best specific match. But their high cycle count and flexibility give MANLY batteries an edge for automated applications.

Final Words

As the pace of delivery continues accelerating, logistics providers require optimization tools equaling the rising tide of parcels. Intelligent automated sorting robots prove uniquely qualified to pump this workflow efficiently by dynamically identifying and diverting items with nimble precision at scale. If you are using sorting robots, make sure to use them from a reputed brand such as MANLY to experience outstanding performance.