New EU Battery Law: A Lithium Battery Game-Changer?

Table of Contents

- New EU Battery Law: A Lithium Battery Game-Changer?

- Impact of the New Battery Law on Battery Design

- Will the battery passport's required disclosures challenge the intellectual property protection of battery designs?

- Exploring the Wide Range of Battery Cycle Lives: Power vs. Storage

- What new requirements will the application of the battery passport place on battery design?

- Will the cell design configuration in the European market trend towards diversification or become more standardized?

- What changes can businesses make in R&D to address new challenges and seize new opportunities?

- Impact of the New Battery Law on Battery Manufacturing

- Battery Passport's Role in Manufacturing: Challenges or Opportunities?

- Carbon Emissions in Different Stages of Battery Production: Is There a Significant Difference?

- Technological Pathways to Reducing Carbon Footprint

- Role and Assistance of Lithium Battery Equipment Companies

- Mastering Solar Power: A Complete Guide

- 2025 When Should I Replace My Forklift Battery?

- Future of Gas Motorcycles Amid New Policies

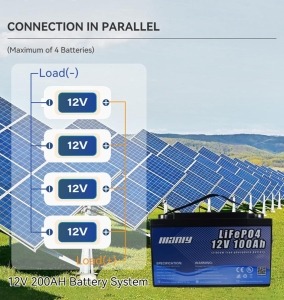

- Series Vs Parallel Ultimate Wiring Guide in 2024

- Impact of the New Battery Law on Battery Design

Impact of the New Battery Law on Battery Design

Will the battery passport's required disclosures challenge the intellectual property protection of battery designs?

According to several pilot test cases from the Global Battery Alliance (GBA), some details related to battery pack and individual cell designs have been revealed. This includes the energy rating of the entire battery pack and the quality of key metals used.However, looking at these three pilot cases, the disclosed information is similar to what battery companies currently share with automakers. The GBA's battery passport doesn't mandate the release of highly confidential details, such as the trace amounts of metals added or unique manufacturing processes. Thus, the current scope of the battery passport disclosures won't impact the intellectual property rights of battery companies.Exploring the Wide Range of Battery Cycle Lives: Power vs. Storage

Battery cycle life is a hot topic. In the pilot cases of the battery passport, Tesla is one of the few companies that disclosed its battery cycle life. However, its disclosed figures are relatively low, especially when compared to some domestic car companies and even lower than those for storage batteries.In reality, cycle lives for both power batteries and storage batteries can vary widely. A typical car recharges twice a week and lasts about 10 years. This doesn't require a battery to have over 5,000 cycle lives.In contrast, storage batteries within a 10 or even 20-year warranty need to achieve close to 7,000 to 12,000 cycles. These wide life ranges are influenced by battery construction, materials used, and key processes.Many businesses face pressure, especially in the storage battery sector. The competitive storage market pushes companies to innovate for low-cost, long-life battery cells. As a result, we see some high cycle life figures on the market, sometimes even up to 14,000 cycles. Yet, many businesses find a gap between lab-observed life and user expectations.Regarding why some companies choose not to disclose cycle life or other performance data: first, there are no mandatory rules yet; second, it may depend on how the battery passport is promoted within the business. To address this, new solutions have emerged in long-life battery design and manufacturing.There are now formulations aimed at long life for storage batteries. These help increase the cycle life from a common 2,000-3,000 to around 5,000-6,000 typical for iron-lithium. New electrolytes, additives, and lithium salts also provide more design and manufacturing possibilities, including new additive use, material choices, and process improvements.In this, modeling simulation plays a vital role in long-life battery R&D. Modern battery models can simulate internal aging mechanisms, predicting the impact of materials, formulas, designs, and manufacturing on life.Moreover, appropriate modeling can reduce the need for lengthy multi-cycle testing, speeding up battery R&D targeting life metrics and thus significantly shortening the R&D cycle.In summary, the issue of battery cycle life covers a wide range of applications for power and storage batteries, unlike singular application needs, resulting in a wide range of cycle lives. As companies face competition and market pressures, seeking solutions for long-life, low-cost batteries becomes key. Modeling and simulation methods play a crucial role, accelerating the battery R&D process.