Unveil Amazing CATL Skateboard Chassis Benefits

Table of Contents

On March 17th at the China Electric Vehicle Forum (2024), the General Manager of CATL (Shanghai) Smart Technology Co., Ltd. disclosed that CATL’s first Lifepo4 lithium battery-based Skateboard Chassis product is slated for mass production in the latter half of this year.

In November last year, CATL announced the launch of its Skateboard Chassis product for B-class sedans, featuring ternary lithium batteries and achieving a breakthrough range of over 1000 kilometers after completing winter and summer testing. This chassis integrates high and low voltage systems, steering and braking systems, and includes a chassis domain controller. It achieved a battery pack assembly efficiency of 75%, with less than 30% degradation at -7°C, a power consumption of 10.5kWh per 100 kilometers, and a 5-minute charge offering 300 kilometers of range.

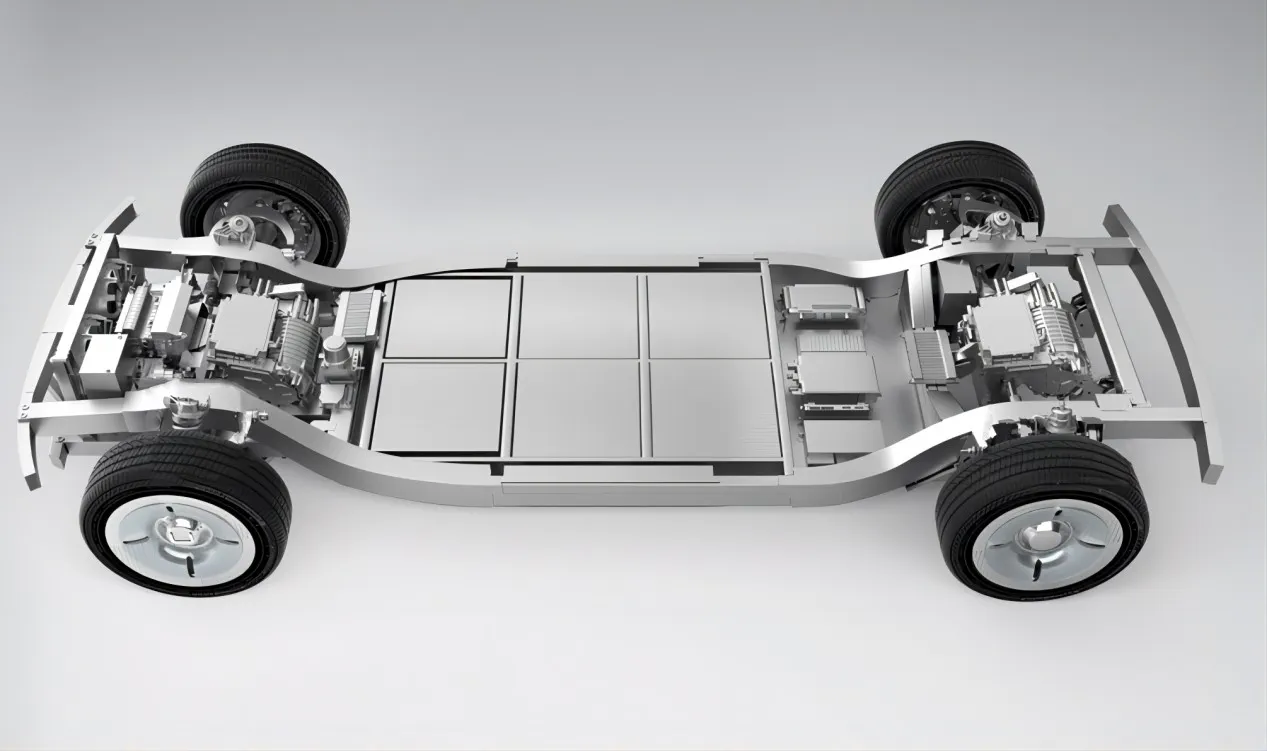

What is a Skateboard Chassis

The concept of the skateboard chassis emerges as a response to the rapid development of new energy vehicles, contrasting the traditional automotive chassis designed around conventional internal combustion engines with mechanical, electrical, and hydraulic integration for vehicle control. Traditional systems utilized separate electronic control units for individual functions, operating independently. The skateboard chassis, however, centralizes around the vehicle’s electrical systems, requiring fewer but more powerful computing units, marking a significant shift towards efficiency and integration.

The skateboard chassis boasts significant potential in the new energy passenger vehicle sector for several reasons. Firstly, the evolving consumer demand towards electric vehicles signifies a shift in vehicle attributes, transitioning from mere transportation tools prioritizing speed and power to large intelligent terminals focusing on scenarios and user experiences. Secondly, amidst the wave of automation, the automotive industry has entered the era of Moore’s Law, questioning the rationale behind automotive companies’ massive investments in already mature, standardized chassis hardware.

CATL has been developing skateboard chassis technology since 2018, initially kickstarting with the CTC technology (placing cells directly into the chassis). In 2021, CATL (Shanghai) Smart Technology Co., Ltd was officially established, setting up an R&D center and testing base while also planning for mass production facilities.

CATL’s skateboard chassis is developed on the foundation of CTC technology, guided by efficiency, light-weight, cost-effectiveness, and safety. Its most notable feature is the decoupling of the upper and lower body, including mechanical, electronic, and software decoupling. Post-decoupling, the chassis encompasses energy (battery), the “three electrics” (motor, electronic control, and battery management), mobility, safety, and sport functionalities, transforming it into an independently operable carrier. Its commercial application aims to better enable automotive companies to conserve resources and focus on enhancing the intelligent user experience.

Advantages of the Skateboard Chassis

Globally, numerous automotive companies are investing in the development of the skateboard chassis. At the forum, CATL further elaborated on the advantages of a power battery company like itself venturing into the development and production of skateboard chassis.

Firstly, it’s about speed. CATL claims it can enable automakers to launch a new vehicle within 18 months, significantly reducing the traditional timelines of 36 to 48 months.

Secondly, it’s about cost savings. Once CATL’s skateboard chassis becomes standardized, the platformization of components and industry sharing will yield significant cost benefits. On one hand, it can lower the initial cost of vehicle development, as multiple car models from an automaker can share the same platform. On the other hand, it can reduce the Bill of Materials (BOM) cost for the chassis itself.

CATL’s skateboard chassis products would only cost approximately one-third of what an automaker would spend on its own development, thus saving automakers 60-70% in development costs. Additionally, CATL’s BOM cost could reduce the automaker’s BOM cost by about 5%, meaning these combined cost savings offer a competitive edge to automakers.

CATL’s Skateboard Chassis: Redefining Vehicle Safety and Design Flexibility

As explained, vehicles equipped with CATL’s skateboard chassis can absorb 85% of the energy from collisions, significantly reducing the impact of vehicle design on safety. Furthermore, the open electrical and mechanical interfaces allow vehicle designers and product managers more freedom in styling and developing intelligent experience features.

In terms of vehicle energy consumption, low-temperature range retention, fast charging based on long-range power battery systems, and both passive and active safety, CATL also demonstrates innovation and advancement. For instance, CATL’s skateboard chassis has a power consumption of only 11 kWh per 100 kilometers, which is lower than any other current domestic or international automobile. A vehicle with a 115-degree ternary lithium battery skateboard chassis can travel 1012 kilometers, whereas other manufacturers might require 15 to 16 kWh to travel the same distance. At -7 degrees Celsius, many new energy vehicles see about a 40% reduction in range, while CATL has achieved a reduction to 33%, with a goal to reduce this to only 30%.

Additionally, fast charging is a strength for CATL, with their skateboard chassis capable of charging from 30% to 80% SOC in just 10 minutes. For this, the company has developed a full-stack 800V electric drive system with an overall efficiency of 91.5%, with the latest tests showing an efficiency of 91.7%.

Currently, automakers collaborating with CATL on the skateboard chassis include NETA Automobile and Vietnam’s VinFast. In November 2022, CATL also signed a “Strategic Cooperation Framework Agreement” with the listed companies Altair and Gecko Technology, aiming to establish an industrial ecosystem alliance in the field of skateboard chassis among others.

In conclusion, CATL is actively promoting the standardization of the skateboard chassis and seeks cooperation with partners throughout the industry.