2024’s Essential Guide to Autonomous Mobile Robots Tech

Table of Contents

- 2024’s Essential Guide to Autonomous Mobile Robots Tech

- Autonomous Robot Definition Explained

- The Mechanics Behind Autonomous Mobile Robots

- The Future of Application of Robotics in Everyday Life

- Advantages of Autonomous Mobile Robots

- Navigating the Differences: AGV vs. AMR

- Which Battery is Suitable for Autonomous Mobile Robots?

- MANLY Battery: Powering the Future of AMRs with LiFePO4 Technology

- Optimal Battery Maintenance for Autonomous Mobile Robots

- Learn More About Battery

Autonomous Robot Definition Explained

1. Introduction to Autonomous Robotics

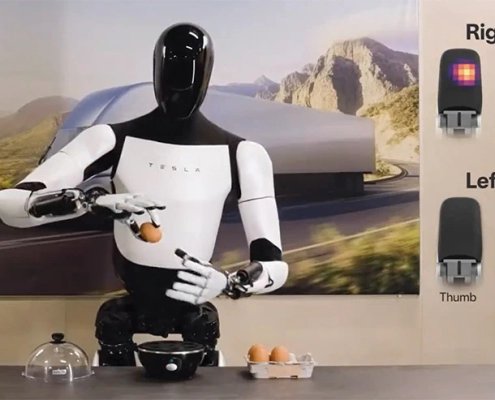

In today’s era of industrial automation and technological advancements, the emergence of Autonomous Mobile Robots (AMRs) marks a significant leap forward. These Self-Driving Robots, exemplifying the autonomous robot definition, blend the functionality of a mechanical arm with a mobile base, equipped with advanced autonomous navigation capabilities. This integration is transforming traditional task execution, previously reliant on manual labor or human-operated machines. By automating such tasks, AMRs drastically cut down on labor dependence, reduce human errors, and greatly enhance production efficiency.

2. Defining and Applying Autonomous Mobile Robots

Fundamentally, an autonomous mobile robot is a robot that understands its environment and navigates independently within it. This definition sets AMRs apart from their forerunners like Automated Guided Vehicles (AGVs), which are limited to tracks or pre-set paths and often need human oversight. In contrast, AMRs utilize a complex array of sensors, artificial intelligence, and machine learning for path planning and environmental navigation, free from the limitations of fixed power sources.

AMRs are increasingly being adopted in industries such as warehousing, logistics, agriculture, and healthcare, to improve operational efficiency, speed, accuracy, and safety. The defining feature of autonomous robots in these applications is their intelligent navigation. For example, if an AMR encounters unexpected obstacles like debris or crowds, it employs advanced technologies like collision avoidance to slow down, stop, or reroute, ensuring uninterrupted task completion. This adaptability makes AMRs indispensable in dynamic and unpredictable settings.

Looking forward to 2024, the integration of autonomous mobile robots in various industries represents not just a trend, but a paradigm shift in business operations optimization. For companies aiming to remain competitive and efficient, understanding and incorporating AMRs into their processes is increasingly becoming a necessity.

The Mechanics Behind Autonomous Mobile Robots

1. Innovative Technologies Powering AMRs

Autonomous Mobile Robots (AMRs) represent a significant leap from their Automated Guided Vehicle (AGV) predecessors. While AGVs are reliant on tracks or predefined routes, often requiring human supervision, AMRs operate with a higher degree of intelligence and independence. Central to the autonomous mobile robot definition is its ability to understand and navigate its environment autonomously. This is achieved through a sophisticated combination of sensors, artificial intelligence (AI), and machine learning technologies, all working in tandem to enable path planning and navigation without the need for wired power sources.

2. How Do Autonomous Mobile Robots Work?

The functionality of AMRs is a testament to the advancements in cloud computing and powerful edge processing technologies. These robots are designed to gather real-time information about their surroundings through local sensors. They control their movement using precise motor and drive setups. The technological cornerstones that are pivotal for the next revolution in AMRs include:

- Machine Vision: Employs one or multiple cameras to observe the environment in a manner akin to human sight. Enhancements in AI, machine learning, and edge processing elevate this capability.

- LIDAR (Light Detection and Ranging): This technology generates a point cloud to create a three-dimensional map of the surrounding area, enhancing the robot’s spatial awareness.

- Edge AI Computing: Powerful processing modules onboard AMRs facilitate real-time decision-making, circumventing the latency inherent in accessing distant cloud resources. Single Board Computers (SBCs) like the Jetson series are popular for edge AI experimentation.

- Wireless Networking: This enables access to cloud and/or local (facility-level) computing resources and coordinates the operation of multiple robots as a collective.

- Motor Drivers: These are crucial for the direct control of the robot’s motors, allowing for precise and controlled movement.

As we delve deeper into 2024, these technologies are not just facilitating the operation of autonomous mobile robots but are also reshaping the landscape of industrial automation. For businesses, understanding and leveraging these advancements is key to harnessing the full potential of AMRs, ultimately leading to enhanced operational efficiency, safety, and productivity.