2025 Guide to Agriculture Battery Solutions for Agricultural Robots

Table of Contents

- 2025 Guide to Agriculture Battery Solutions for Agricultural Robots

- What Are Agricultural Robots?

- Why Lithium Agriculture Battery is Essential for Agricultural Robots

- Applications of Lithium Agriculture Battery in Agricultural Robots

- How to Choose the Best Lithium Battery Manufacturer

- Evaluating Manufacturer Expertise and Capabilities

- Who Are the Top Lithium Battery Manufacturers for Agricultural Robots?

- Conclusion

- FAQ

- Hot Search

- Learn More About Battery

The agricultural industry is rapidly evolving, with automation becoming a cornerstone of modern farming. Agricultural robots are revolutionizing how tasks like planting, harvesting, and livestock management are carried out, offering greater efficiency and precision. Central to the success of these technologies is the use of advanced agriculture battery solutions. Lithium batteries, in particular, have emerged as the preferred power source for these robots, providing unmatched reliability, extended lifespans, and compatibility with diverse farming equipment. This article explores the critical role of lithium agriculture batteries in driving innovation and sustainability in the agricultural sector.

What Are Agricultural Robots?

Agricultural robots are automated machines designed to perform repetitive, labor-intensive tasks in farming. These include autonomous tractors, drones, crop-monitoring machines, and automated harvesting robots. By leveraging advanced technologies like GPS, sensors, and AI, these robots are revolutionizing the agricultural industry with greater efficiency, precision, and sustainability.

How Do Agricultural Robots Work?

Agricultural robots operate by combining sensors, cameras, and advanced algorithms to perform tasks autonomously. For example, drones equipped with high-resolution cameras can monitor crop health, while harvesting robots use vision systems to detect and pick ripe fruits without damaging them. Mobile robots, like autonomous tractors, rely on GPS for navigation, enabling precise automated planting and harvesting. By integrating these technologies, robots can independently execute complex tasks, reducing the need for manual labor and improving productivity.

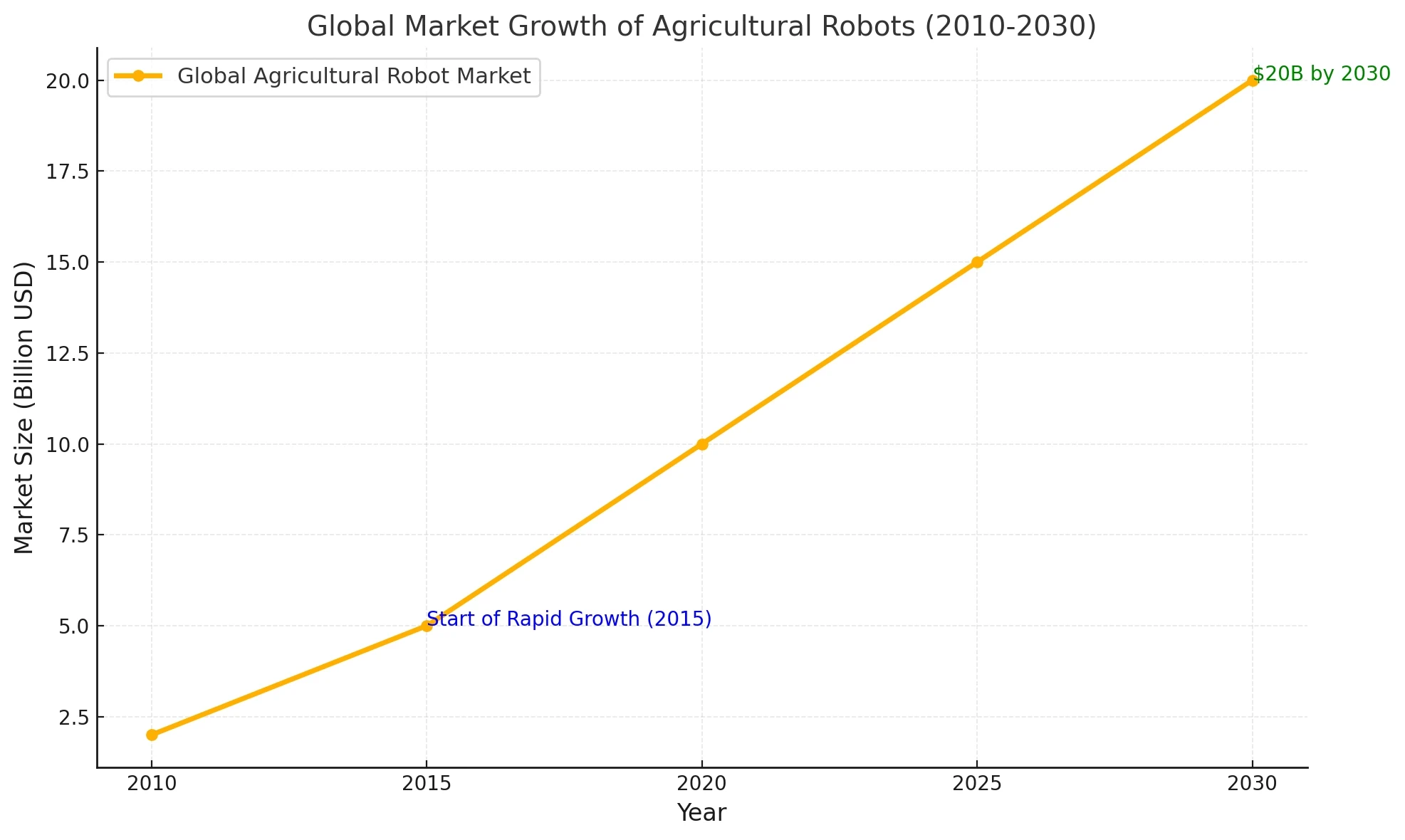

Global Market Growth and Future Trends

The global market for agricultural robots has seen rapid growth over the past decade, driven by advancements in robotics and agriculture and the adoption of sustainable technologies like lithium agriculture battery solutions.

- Historical Growth: Since the 2010s, the use of farming robots has expanded significantly, with countries like the U.S., Japan, and the EU leading the way. Initiatives such as the U.S. “National Robotics Initiative” and the EU’s “Horizon 2020” program have allocated billions of dollars for the research and deployment of agricultural robots.

- Future Projections: By 2030, the global agricultural robot market is projected to reach $20 billion. This growth is fueled by increased demand for automation in response to labor shortages and sustainability goals. Automated harvesting and planting robots are expected to dominate the market due to their ability to enhance efficiency and reduce waste.

- Role of Lithium Batteries: The integration of lithium agriculture battery solutions has been pivotal. These batteries provide high energy density and reliability, ensuring longer operational hours for robots in tasks like precision planting, weeding, and harvesting. As battery technology advances, robots will become even more efficient and adaptable to various agricultural tasks.

Why Lithium Agriculture Battery is Essential for Agricultural Robots

Lithium agriculture battery technology plays a pivotal role in advancing the functionality of agricultural robots. With their high energy density, lightweight design, and resilience in challenging environments, lithium batteries ensure reliable performance for tasks ranging from seeding to crop monitoring, making them indispensable in modern farming operations.

Key Features of Lithium Agriculture Battery

High Energy Density for Extended Operation

Lithium agriculture battery systems deliver much higher energy density compared to lead-acid batteries, enabling agricultural robots to operate for significantly longer periods without recharging. This is particularly important for tasks that require extended autonomy, such as drone-based crop monitoring or autonomous tractor operations.

Comparison:

| Battery Type | Energy Density (Wh/kg) | Operational Impact |

|---|---|---|

| Lead-Acid Battery | 30-50 | Requires frequent recharging; limited coverage per task. |

| Lithium Battery | 150-200 | Powers robots for 3-5x longer periods, enabling larger operational areas. |

Key Benefits:

- Robots can cover up to 500 acres on a single charge with lithium batteries, compared to 150 acres with lead-acid batteries.

- Ideal for time-sensitive operations like planting and harvesting.

Lightweight Design Enhancing Mobility

Lithium batteries are substantially lighter than lead-acid batteries, which directly impacts the mobility and efficiency of agricultural robots like drones and ground vehicles. Reduced weight not only allows for easier navigation but also increases the payload capacity and flight duration of drones.

Comparison:

| Battery Type | Weight for Equivalent Energy (50Ah) | Impact on Mobility |

|---|---|---|

| Lead-Acid Battery | ~15 kg (33 lbs) | Reduces maneuverability and limits payload. |

| Lithium Battery | ~5 kg (11 lbs) | Improves mobility; increases drone flight time by 30-40%. |

Example for Drones:

- A drone equipped with a lithium agriculture battery can achieve up to 40 minutes of flight time compared to 25 minutes with a lead-acid battery.

- Enhanced mobility reduces energy consumption, allowing robots to cover diverse terrains more effectively.

Durability in Extreme Conditions

Lithium agriculture battery systems are designed to withstand the demanding conditions of farming, including extreme temperatures and repeated charge cycles. Lead-acid batteries, on the other hand, tend to degrade quickly under similar conditions, requiring frequent replacements.

Comparison:

| Battery Type | Temperature Range | Cycle Life (Full Charge-Discharge) | Operational Reliability in Extreme Environments |

|---|---|---|---|

| Lead-Acid Battery | -10°C to 40°C (14°F to 104°F) | 500-800 cycles | Performance drops in high/low temperatures. |

| Lithium Battery | -20°C to 60°C (-4°F to 140°F) | 2000-5000 cycles | Operates reliably across seasons and conditions. |

Benefits for Agricultural Robots:

- Continuous operation in both hot summers and cold winters.

- Reduces downtime caused by battery failures, ensuring consistent performance during peak farming seasons.

How Agriculture Battery Enhances Farming Efficiency

- Reliable Power Supply for Key Tasks

Lithium agriculture battery solutions deliver consistent and dependable energy for critical farming operations. Whether powering drones for crop monitoring or autonomous tractors for plowing and seeding, these batteries ensure uninterrupted performance, helping farmers maximize productivity. - Reduced Maintenance and Downtime

Compared to traditional batteries, lithium agriculture battery systems require minimal maintenance. Their long lifespan and superior durability result in fewer replacements and repairs, reducing downtime and operational costs for farmers relying on agricultural robots. - Eco-Friendly Energy Solution

The adoption of lithium agriculture battery technology supports sustainable farming by reducing reliance on fossil fuels and lowering greenhouse gas emissions. These batteries contribute to environmentally friendly practices, aligning with global sustainability goals and fostering a cleaner, more efficient agricultural sector.

Discover how an Electric Tractor battery can boost your farm’s efficiency and sustainability. Read how long does a tractor battery last today!

Applications of Lithium Agriculture Battery in Agricultural Robots

Lithium agriculture batteries are transforming the functionality and efficiency of agricultural robots, powering a wide array of technologies in farming, from autonomous machinery to drones and livestock management systems.

Farm Machinery & Equipment

Lithium agriculture batteries are a vital component of farm machinery such as autonomous tractors and harvesters. These machines reduce the reliance on human labor while increasing the precision and efficiency of operations like plowing, seeding, and harvesting.

Why Lithium Agriculture Battery Stands Out:

- Extended Operational Hours: Lithium batteries support longer work cycles, enabling machinery to cover larger areas without frequent recharges.

- Enhanced Precision: The stable voltage output ensures consistent performance, which is critical for tasks like planting seeds at precise intervals.

Comparison: Lithium vs. Lead-Acid Batteries

| Feature | Lead-Acid Battery | Lithium Agriculture Battery |

|---|---|---|

| Energy Density | 30-50 Wh/kg | 150-200 Wh/kg |

| Operational Range | ~4-5 hours | ~10-12 hours |

| Weight Impact | Heavy (20-30% increase in tractor weight) | Lightweight, improving mobility |

| Lifespan | ~500-800 charge cycles | ~2000-5000 charge cycles |

Example: An autonomous tractor with a lithium agriculture battery can operate for 12 hours non-stop, covering approximately 500 acres, compared to 5 hours and 200 acres with a lead-acid battery.

Agriculture Drone and Precision

Drones are among the most versatile agricultural robots, used for crop health monitoring, precision spraying, and mapping. Lithium agriculture batteries significantly enhance their operational performance.

Key Benefits for Agricultural Drones:

- Prolonged Flight Time: Lightweight lithium batteries allow drones to achieve up to 40 minutes of flight time, compared to 20-25 minutes with traditional batteries.

- Higher Payload Capacity: Reduced weight enables drones to carry additional sensors or larger quantities of spray chemicals, improving efficiency.

Case Study:

- A DJI MG-1S agriculture drone, equipped with a 12,000mAh lithium battery, can complete 25 minutes of spraying per charge, covering approximately 15 acres. With lead-acid batteries, the drone would need recharging every 12 minutes, significantly slowing down operations.

Livestock Management Robots

In livestock farming, robots powered by lithium agriculture batteries are utilized for feeding, health monitoring, and milking automation. These robots ensure consistent care and reduce labor costs.

Why Lithium Agriculture Battery is Ideal for Livestock Robots:

- Reliable Power Supply: Lithium batteries provide consistent energy, ensuring uninterrupted operation during feeding or milking schedules.

- Durability: Designed to withstand harsh conditions in barns, such as extreme temperatures and high humidity.

- Efficiency: Reduces downtime due to minimal maintenance and long lifespan.

Comparison in Livestock Operations:

| Task | Lead-Acid Battery Impact | Lithium Agriculture Battery Impact |

|---|---|---|

| Feeding Robots | Requires frequent recharging, disrupting feeding cycles | Ensures continuous operation without interruption |

| Milking Robots | Limited runtime reduces throughput | Supports 24/7 milking schedules |

| Health Monitoring Robots | Inconsistent data collection due to downtime | Provides reliable, real-time health data |

Lithium agriculture batteries have become the backbone of modern agricultural robots, enabling advancements in precision, efficiency, and sustainability across farming operations. Whether for autonomous machinery, drones, or livestock robots, these batteries are paving the way for smarter, more efficient agriculture. Let me know if you’d like further refinements!

How to Choose the Best Lithium Battery Manufacturer

The Importance of Choosing Reliable Suppliers

A trusted battery supplier ensures the use of Grade A battery cells, which are essential for delivering consistent performance and longer lifespans for agricultural robots. In contrast, unreliable suppliers may use used battery cells or lower-grade cells, which can significantly impact the quality, safety, and durability of the battery.

Why Grade A Battery Cells Are Crucial:

- Performance and Reliability:

Grade A battery cells are manufactured to meet stringent quality standards, offering uniform capacity, consistent performance, and higher energy density.- In contrast, used or Grade B cells often have degraded capacity and may fail under demanding conditions, leading to unexpected downtime and costly replacements.

- Extended Cycle Life:

The cycle life of a battery (the number of charge and discharge cycles it can sustain before capacity drops below 80%) is a critical factor for long-term use in agricultural robots.

Comparison of Grade A vs. Used Battery Cells:

| Battery Cell Type | Cycle Life (Charge Cycles) | Operational Impact |

|---|---|---|

| Grade A Battery Cells | 3,000-5,000 cycles | Long-term reliability, minimal replacements, ideal for robots with frequent use. |

| Used or Grade B Cells | 500-800 cycles | Reduced lifespan, frequent failures, and increased maintenance costs. |

Example: A trusted supplier providing Grade A battery cells ensures a battery lasts for up to 5 years, depending on usage. In contrast, used cells may require replacement within 6-12 months, leading to higher total ownership costs.

- Safety Standards:

Used cells often lack uniformity in capacity and voltage, increasing the risk of overheating, short circuits, and other safety hazards. Trusted suppliers guarantee compliance with global certifications like UL, CE, and UN38.3, ensuring both performance and safety.

Key Takeaway:

When selecting a lithium agriculture battery manufacturer, always prioritize suppliers that use Grade A battery cells. This choice ensures longer battery life, consistent performance, and safer operations for agricultural robots, significantly reducing long-term costs and operational risks. Let me know if you’d like to expand on this section!

Customization: Tailoring Batteries to Specific Robotic Needs

Custom lithium agriculture batteries are essential for ensuring compatibility, protection, and cost-efficiency across various agricultural equipment. Here’s why custom batteries are the ideal solution:

1. Compatibility with Different Equipment Brands and Models

Custom batteries can be designed to fit specific dimensions and power requirements of various agricultural equipment from different manufacturers. This ensures seamless installation without the risk of mismatched sizes or specifications.

- Example: An autonomous tractor from Manufacturer A requires a 48V battery with a compact design, while a sprayer from Manufacturer B needs a 24V battery with a unique shape. A single trusted battery manufacturer can create both batteries to match these requirements, eliminating the need for extensive modifications or sourcing issues.

2. Enhanced Protection for High Dust and Water Environments

Agricultural robots operating in dusty fields or during irrigation processes require batteries with high waterproof and dustproof ratings (e.g., IP67 or IP68). Custom-designed batteries can meet these environmental protection standards, ensuring durability and safety.

- Example: A crop-monitoring drone used in irrigation-heavy fields benefits from a custom IP68-rated battery that prevents water ingress, maintaining reliable performance during operations.

3. Shockproof and Impact-Resistant Designs

For equipment exposed to harsh conditions, such as rocky fields or areas prone to collisions, custom batteries can be reinforced with shockproof and impact-resistant materials to prevent damage and ensure longevity.

- Example: A robotic harvester operating in rugged terrain is fitted with a custom battery encased in a reinforced shell to withstand vibrations and impacts, protecting the internal components and extending the battery’s lifespan.

4. One-Stop Customization for All Equipment Needs

Working with a single battery manufacturer for custom solutions eliminates the hassle of sourcing batteries from multiple retailers. Farmers can have all their battery needs fulfilled by one supplier, simplifying procurement and reducing logistics complexity.

- Example: Instead of purchasing one waterproof battery from Supplier A, another shockproof battery from Supplier B, and a lightweight drone battery from Supplier C, a single manufacturer can provide all three solutions. This saves time and reduces the effort of coordinating multiple orders.

5. Cost Savings Through Bulk Purchases

Purchasing custom batteries from one battery manufacturer often results in better pricing due to bulk discounts. In contrast, sourcing from multiple vendors can increase overall costs because of smaller order quantities and higher per-unit prices.

- Example: A farmer ordering 50 batteries for drones, tractors, and sprayers from one manufacturer gets a significant discount. If these orders are split among different retailers, the per-unit cost rises by 20-30%, inflating the total expenditure.

Custom lithium agriculture batteries are more than just power sources—they are tailored solutions that enhance compatibility, protection, and cost-efficiency for modern agricultural robots. By choosing a trusted manufacturer, farmers can simplify their operations while improving performance and reducing long-term costs.

Evaluating Manufacturer Expertise and Capabilities

Not all battery manufacturers are created equal. Here’s how to evaluate potential partners:

- Production Capacity and Technology:

A trusted battery supplier should have the capacity to meet both large-scale and specialized demands. Manufacturers like MANLY Battery, for instance, produce over 6MWh of battery cells daily, ensuring reliable supply for various agricultural applications. - Technological Advancements:

Look for manufacturers that invest in research and development to stay ahead of industry trends. Advanced features like high-energy-density batteries and extended cycle life demonstrate a commitment to innovation. - Certifications and Quality Assurance:

Reputable manufacturers provide globally recognized certifications such as UL, CE, and UN38.3, ensuring the batteries meet strict safety and quality standards. Additionally, comprehensive quality control processes guarantee consistent performance. - After-Sales Support and Warranty:

A reliable manufacturer offers robust after-sales support, including technical assistance and warranties (e.g., 10 years). This level of service provides peace of mind and ensures a return on investment.

Who Are the Top Lithium Battery Manufacturers for Agricultural Robots?

Selecting the right battery manufacturer is critical for ensuring the reliable performance of agricultural robots. Below are three highly regarded battery suppliers that offer high-quality lithium agriculture batteries tailored to meet the diverse needs of the farming industry.

MANLY Battery

Overview:

MANLY Battery, based in China, has over 13 years of experience as a leading battery manufacturer. Renowned for its dedication to quality and innovation, MANLY specializes in producing LiFePO4 and lithium-ion batteries for various applications, including agricultural robots, solar energy systems, and forklifts.

Why Choose MANLY Battery?

- Production Excellence:

MANLY produces over 6MWh of battery cells daily and assembles more than 3,000 batteries every day, ensuring reliable supply for large-scale agricultural operations. - Customization Capabilities:

Their bespoke services offer tailored solutions, from voltage and capacity to physical dimensions, making them ideal for diverse farming equipment like drones, autonomous tractors, and sprayers.- Example: A farmer needing a shock-resistant and waterproof battery for rugged terrain can get a custom solution from MANLY to meet these exact requirements.

- Global Certifications:

MANLY products adhere to certifications such as UN38.3, IEC62133, UL, and CE, guaranteeing top-tier safety and performance standards. - Durability and Longevity:

With a lifespan of up to 5,000 charge cycles, MANLY’s batteries operate reliably in extreme temperatures ranging from -20°C to 75°C (-4°F to 167°F), making them perfect for harsh agricultural environments.

Key Feature:

MANLY batteries offer up to 95% energy efficiency, significantly outperforming traditional lead-acid batteries with only 70% efficiency. This ensures faster charging and extended runtime for agricultural robots.

East Penn Manufacturing

Overview:

East Penn Manufacturing is a prominent U.S.-based battery manufacturer known for its extensive range of energy solutions, including lead-acid and lithium batteries. Their products cater to various industries, with a growing focus on agricultural applications.

Why Choose East Penn?

- Commitment to Quality:

East Penn’s lithium batteries are engineered for consistency and reliability, supporting long operating hours for equipment like autonomous tractors and crop-monitoring robots. - Eco-Friendly Practices:

As a leader in sustainability, East Penn emphasizes environmentally responsible manufacturing processes, ensuring their batteries meet stringent eco-friendly standards. - Wide Availability:

Their extensive distribution network across North America ensures easy access to their products and reliable after-sales support.

Key Feature:

East Penn’s lithium batteries provide a balance between affordability and performance, making them a great choice for farmers seeking dependable power for mid-range agricultural machinery.

Relion Battery

Overview:

Relion Battery, headquartered in South Carolina, specializes in premium lithium battery solutions, particularly LiFePO4 technology. Their products are designed for high-performance applications, including agricultural robots and precision farming equipment.

Why Choose Relion?

- Advanced Technology:

Relion’s batteries feature advanced Battery Management Systems (BMS) for optimal performance and safety, ensuring consistent power delivery for high-demand farming tasks. - Lightweight and Compact:

Their lightweight design makes them ideal for drones and other robotic systems, enhancing mobility and operational efficiency.- Example: A crop-spraying drone equipped with a Relion battery achieves longer flight durations, covering more acreage in less time.

- Extended Lifespan:

With a lifespan of 3,000-5,000 charge cycles, Relion batteries are a cost-effective choice for long-term use. - Sustainability Focus:

Their batteries are 100% recyclable, aligning with the increasing demand for eco-friendly solutions in agriculture.

Key Feature:

Relion batteries are particularly suited for precision agriculture, offering reliable power for sensors, drones, and other advanced technologies that require uninterrupted energy supply.

Conclusion

In conclusion, lithium agriculture batteries have become the backbone of modern agricultural robots, enabling them to perform critical farming tasks with unmatched efficiency and precision. From autonomous tractors to precision drones and livestock management systems, these batteries provide the reliable power needed to meet the demands of modern agriculture. As farmers increasingly adopt automation to enhance productivity and sustainability, the role of high-quality agriculture batteries cannot be overstated. By partnering with trusted battery manufacturers and suppliers, the agricultural industry can continue to innovate, ensuring long-term success and environmental stewardship.

FAQ

1. How long do farm tractor batteries last?

A: Farm tractor batteries typically last 3 to 5 years, depending on usage, maintenance, and environmental conditions. Lithium batteries, often used in modern tractors, can last up to 10 years or 2,000-5,000 charge cycles, making them a more durable option compared to traditional lead-acid batteries.

2. Which robot is used for agriculture?

A: Various agricultural robots are used in farming, including autonomous tractors for plowing and seeding, drones for crop monitoring and spraying, and harvesting robots designed to pick fruits and vegetables. These robots enhance efficiency, reduce labor dependency, and support precision agriculture.

3. What type of battery is used in robots?

A: Most robots, including agricultural robots, use lithium batteries due to their high energy density, lightweight design, and long lifespan. For specific agricultural applications, such as drones or heavy-duty machinery, LiFePO4 batteries are commonly chosen for their reliability and durability in harsh environments.