Future Tech: Innovations in Lithium Ion Battery Separator

Table of Contents

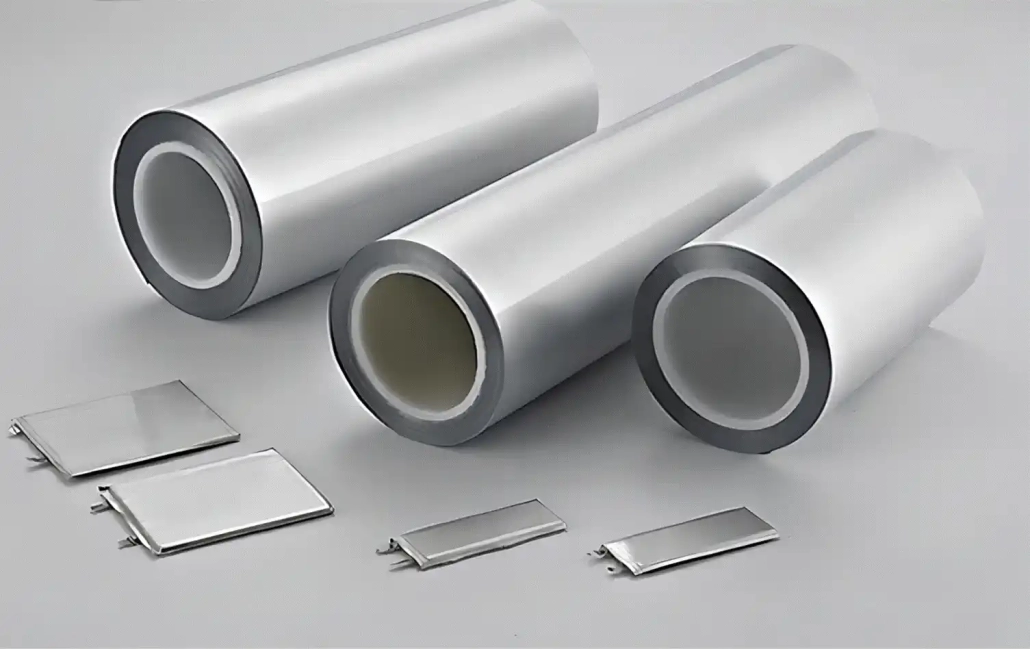

What is Separator in Lithium Ion Battery

The separator is one of the four key materials in a lithium-ion battery. It’s like the heart of the battery. The separator acts as both an insulator and a semi-permeable layer. Why is it important? Well, it does two main things:

- First, it keeps the battery safe. The separator makes sure the positive and negative ends of the battery don’t touch. This helps avoid any short circuits.

- Second, the separator helps the battery work right. When you charge or use the battery, lithium ions move through tiny holes in the separator. This separator is a thin sheet with lots of super-small holes. These holes need to be just the right size: big enough for the lithium ions to move but small enough to block any electric flow. This way, the battery can charge and work correctly.

Making the perfect separator is no easy job. The holes need to be evenly spread out and consistent. There’s a lot of advanced tech that goes into making one. The better the separator, the better the battery will work. This is why making a good separator is a challenging task with high technical barriers.

For a top-notch battery, the separator needs to be just right in many ways. It has to be even in thickness, strong (so it doesn’t break or get punctured), and stable in different conditions. Getting all these features perfect is a big challenge.

If the separator isn’t up to par, the battery might not work as well. It could affect the battery’s resistance, how much power it can hold, how long it lasts, and how safe it is. The separator is really one of the most critical parts in the battery-making process.

Right now, most commercial battery separators are made from materials like polyethylene (PE) and polypropylene (PP). Regular 3C batteries usually have a single layer of PE or PP. But power batteries might have two layers like PE/PP or even three layers like PP/PE/PP.

The cost to make a separator includes the cost of materials, energy, labor, and wear and tear over time.

How to Make a Lithium Ion Battery Separator

There are two main methods to make lithium-ion battery separators: the dry process and the wet process.

Starting with the dry method, there are two techniques. One is the single-stretch, and the other is the double-stretch. The double-stretch technique was developed by the Chinese Academy of Sciences’ Institute of Chemistry. However, it’s not widely used now because it didn’t meet the performance standards people wanted. The equipment for the dry process is pretty reliable, and the whole thing is pretty straightforward. One big advantage is that the dry method doesn’t have much heat shrinkage, so it’s safer. Plus, it’s cheaper. This makes it great for making separators for storage batteries, consumer batteries, and iron phosphate lithium power batteries.

On the other hand, the wet method costs more than the dry one. But it has its perks. The separators made with the wet process have uniform and well-aired holes. They can also be thinner and lighter. Many think that “wet-base + coated layer” separators are best for high-energy-density power batteries. Right now, the wet method is leading the way. More separators are made using the wet process than the dry one, and it’s the go-to choice in the market.

Future Trends in Lithium Ion Battery Separator Technologies

Polyolefin separators have a noticeable issue: they don’t handle heat very well. So, improving these separators by adding a coating is becoming the way to go. When we say they’re not good with heat, we mean they can’t withstand high temperatures. The separators, made of materials like PE and PP, are essentially plastics. Think of the plastic bags and cups we use every day. They deform or even shrink into a ball when exposed to heat. If it gets hotter, they can even catch fire.

Now, when we talk about “coating,” we’re essentially discussing adding a new layer on the original separator to make it better. Once coated, these separators can handle heat and resist punctures much better. This is crucial when we think about how batteries can get hot during fast charging. The coated separators prevent the battery’s positive and negative ends from touching and causing fires or explosions.

The rise in popularity of the wet method separators is partly because this coating addresses safety concerns linked to this method. The coating decreases the separator’s tendency to shrink when heated. It also significantly improves its puncture resistance. Plus, it doesn’t mess with the separator’s breathability, ensuring the flow of lithium ions. Additionally, the coating lets the separator soak better in the electrolyte, lowering the battery’s internal resistance and boosting its power output. This can extend the battery’s lifespan.

Overall, compared to dry method separators, the wet method with coating offers uniform hole sizes, good porosity, and breathability. And compared to standard wet method separators, it notably improves puncture resistance and heat stability. That makes it the top choice for separators in ternary material batteries. With the push for thinner separators and the ever-growing demand for safer batteries, coated separators are taking over the market.

There are two main types of coatings out there: inorganic and organic. Inorganic coatings, using ceramics, boehmite, aluminum oxide, mainly focus on improving the separator’s heat stability. On the other hand, organic coatings like aramid and PVDF enhance the separator’s chemical properties like ionic conductivity, cycling performance, and rate performance. Aramid coating is especially popular right now.

In the real world of production, manufacturers often use a mix of different materials for coating. The mix and the solvents they choose vary, leading to different formulas. This is where we see differences in the coated separators from one manufacturer to the next.