LiFePO4 vs Lead Acid: Cost Efficiency for Enterprises

Initial Costs

When comparing the costs of LiFePO4 battery and lead acid battery systems, the initial purchase price is an important factor. A typical 12V 100Ah lead acid battery costs around $90, while a comparable LiFePO4 battery is priced at about $190. Although the upfront cost of a LiFePO4 battery is higher, it’s essential to consider the long-term financial benefits.

Lifespan and Cycle Cost

The lifespan of a battery significantly impacts its overall cost efficiency. Lead acid batteries usually last for about 300 charge cycles, maintaining 60% of their capacity. In contrast, LiFePO4 batteries can handle up to 2000 cycles while still retaining 60% capacity. When we break down the cost per cycle, a lead acid battery costs approximately $0.30 per cycle ($90/300 cycles). On the other hand, a LiFePO4 battery costs about $0.095 per cycle ($190/2000 cycles). This lower per-cycle cost demonstrates the superior cost efficiency of LiFePO4 batteries over their lifespan.

Maintenance Costs

Another critical aspect to consider is the maintenance cost. Lead acid batteries require regular maintenance, including watering, cleaning terminals, and performing equalization charges. This maintenance can cost around $50-$100 per year. Conversely, LiFePO4 batteries require minimal maintenance, with annual costs estimated at $10-$20 primarily for occasional cleaning. This significant reduction in maintenance needs further enhances the cost efficiency of LiFePO4 batteries.

Case Study:

Golf Cart Batteries

To illustrate these points, let’s look at the cost comparison for golf cart batteries. A set of lead acid batteries for a golf cart typically costs between $800 and $1,500, while a set of LiFePO4 batteries costs around $2,000. Although the initial cost of LiFePO4 batteries is higher, they offer a longer lifespan (8-10 years compared to 3-4 years for lead acid batteries) and significantly lower maintenance costs. This results in long-term savings and reduced hassle for businesses that rely on golf carts.

Forklift Battery Costs

Forklift batteries provide another excellent comparison. Lead acid forklift batteries cost between $2,000 and $6,000, whereas LiFePO4 forklift batteries range from $17,000 to $20,000. Despite the higher initial investment, LiFePO4 batteries offer longer service life and minimal maintenance, translating to lower total ownership costs over time. For instance, the need for regular watering, cooling periods, and vent inspections with lead acid batteries increases downtime and labor costs. In contrast, LiFePO4 batteries eliminate these requirements, allowing for more efficient operations.

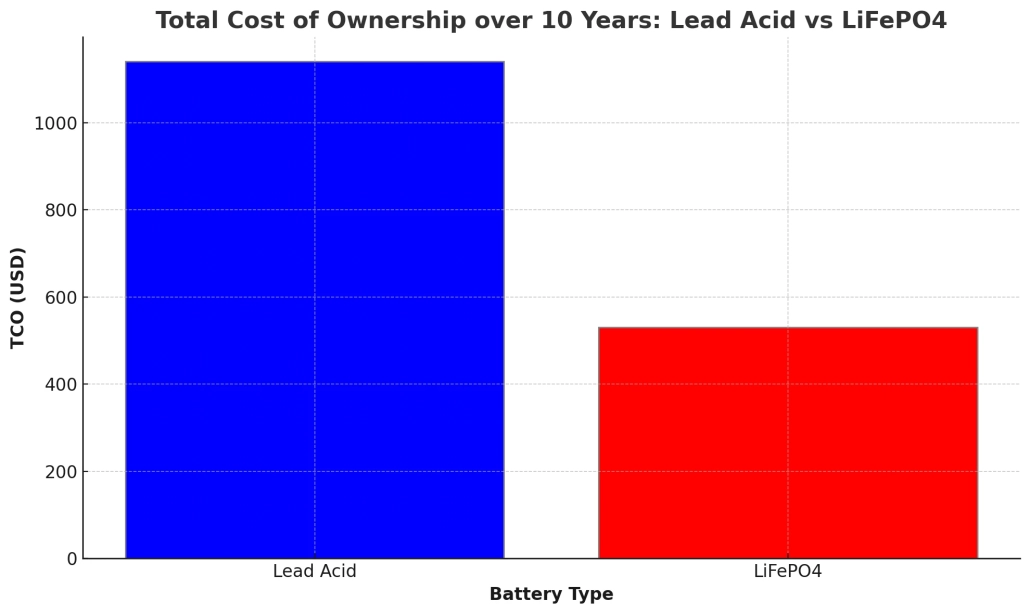

Total Cost of Ownership

The total cost of ownership (TCO) is a crucial metric for enterprises evaluating battery options. While lead acid battery systems might seem cheaper initially, their shorter lifespan, higher maintenance costs, and lower efficiency lead to higher long-term expenses. LiFePO4 battery systems, despite a higher initial cost, prove more economical over time due to their durability, low maintenance, and superior performance.

LiFePO4 vs Lead Acid: Performance and Reliability

Choosing the right battery for your business is crucial. In this section, we will compare the performance and reliability of LiFePO4 battery and lead acid battery systems. Understanding these differences can help you make an informed decision for your company.

Size and Weight

One of the most noticeable differences is in size and weight. Lead acid battery systems are larger and heavier, typically weighing between 15 to 30 kilograms. In contrast, LiFePO4 battery systems are more compact and lighter, weighing only 2.5 to 3.0 kilograms. This difference makes LiFePO4 battery systems easier to handle and install.

Energy Density

The energy density of a LiFePO4 battery is much higher than that of a lead acid battery. For the same volume, LiFePO4 batteries can store three to four times more energy than lead acid batteries. This higher energy density means that LiFePO4 battery systems can provide longer runtimes and more power in a smaller package.

Lifespan

When it comes to lifespan, LiFePO4 battery systems far outperform lead acid battery systems. A typical lead acid battery can handle around 300 charge cycles before its capacity drops to 60%. In comparison, LiFePO4 batteries can last for over 2000 cycles while maintaining more than 80% of their capacity. This longer lifespan means fewer replacements and lower costs over time.

Safety

Safety is another critical factor. Lead acid batteries can pose significant safety risks, including the potential for explosions under severe impact. They contain corrosive acids that can be hazardous if spilled. LiFePO4 battery systems, however, are much safer. They have undergone rigorous safety testing and are resistant to explosions even under extreme conditions. This makes them a safer choice for various applications.

Temperature Range

The operating temperature range of LiFePO4 batteries is also broader than that of lead acid batteries. Lead acid batteries can function between -20°C to 50°C, while LiFePO4 batteries can operate from -20°C to 75°C. This wider temperature range ensures that LiFePO4 batteries perform reliably in both hot and cold environments.

Charging Efficiency

LiFePO4 batteries also charge faster and more efficiently than lead acid batteries. A fully discharged lead acid battery can take 8 to 10 hours to charge, whereas a LiFePO4 battery can be charged in just 40 minutes with the appropriate charger. This rapid charging capability is particularly beneficial for businesses that need to minimize downtime.

Environmental Impact

In terms of environmental impact, LiFePO4 batteries are a greener choice. Lead acid batteries contain harmful heavy metals and acids that can cause environmental damage if not disposed of properly. LiFePO4 batteries, on the other hand, do not contain toxic metals and are easier to recycle, making them a more environmentally friendly option.

Case Study: Forklifts

Forklifts are a prime example of where the benefits of LiFePO4 battery systems shine. Traditional lead acid forklift batteries cost between $2,000 and $6,000 and need to be replaced every 2-3 years due to their limited cycle life. Additionally, they are only about 75% efficient, leading to significant energy wastage.

In contrast, LiFePO4 forklift batteries cost between $17,000 and $20,000 but are up to 99% efficient and can last up to 10 years. This not only reduces replacement costs but also cuts down on energy bills. Moreover, LiFePO4 batteries enhance workplace safety by eliminating the need for regular maintenance and reducing the risk of accidents.

Case Study: Golf Carts

Golf carts also benefit greatly from LiFePO4 battery technology. Lead acid batteries for golf carts typically cost around $800 to $1,500 and need to be replaced every 3-4 years. They also require regular maintenance, including watering and cleaning, which adds to the overall cost.

LiFePO4 batteries for golf carts, on the other hand, have a higher initial cost of about $2,000 but offer significant advantages. They last 8-10 years, require minimal maintenance, and charge much faster. This means that golf carts equipped with LiFePO4 batteries can spend more time on the course and less time in the maintenance shop. Additionally, the consistent power output and lighter weight of LiFePO4 batteries improve the performance and handling of golf carts, making them more reliable and efficient.

LiFePO4 Battery Manufacturer: Choosing the Right Supplier

Production Capacity

When selecting a LiFePO4 battery manufacturer, it’s essential to consider their production capacity. A high-capacity manufacturer can ensure a steady supply of batteries, meeting your business needs without delays. For example, MANLY Battery, a leading name in China, produces an impressive 6MWh of battery cells and packs daily. They assemble over 3,000 batteries each day in their state-of-the-art facilities located in Shenzhen, Dongguan, and Huizhou.

Product Versatility

A good LiFePO4 battery manufacturer should offer a wide range of products to cater to various applications. MANLY Battery provides an extensive assortment of LiFePO4 and lithium-ion batteries, ranging from 6V to 72V. Their batteries are designed for diverse uses, including solar energy storage, industrial energy storage, advanced robotics, base station support, solar street lights, and uninterruptible power supplies (UPS).

Customization Options

Every business has unique requirements. Therefore, a top LiFePO4 battery manufacturer should offer customization options. MANLY Battery excels in this area by providing bespoke services that allow clients to customize voltage, capacity, aesthetics, and other specifications. This ensures that each battery perfectly matches the client’s needs.

Certifications and Quality Assurance

Global certifications are a testament to a manufacturer’s commitment to quality and safety. MANLY Battery holds prestigious certifications such as UN38.3, IEC62133, UL, and CE. These certifications indicate adherence to international standards, ensuring the batteries are safe and reliable.

Warranty and Support

A reliable warranty is crucial when choosing a LiFePO4 battery manufacturer. MANLY Battery offers a decade-long warranty, underscoring their confidence in the quality and durability of their products. This long-term warranty provides peace of mind, knowing that the batteries are built to last.

Safety Features

Safety is paramount, especially for industrial applications. MANLY Battery integrates advanced safety features in their batteries, such as short circuit protection, overcharge safeguards, and overcurrent preventions. These features ensure that the batteries operate safely, even under severe conditions.

Performance and Efficiency

Performance and efficiency are critical factors in battery selection. MANLY Battery’s LiFePO4 batteries boast an energy efficiency rate of 95%, significantly higher than the traditional lead-acid batteries, which are around 70%. This high efficiency means faster charging and lower energy consumption, making them a cost-effective choice.

Conclusion

In conclusion, LiFePO4 battery systems offer numerous advantages over traditional lead acid battery systems. Their higher energy density, longer lifespan, faster charging times, and lower maintenance costs make them an excellent choice for various applications, including forklifts and golf carts. As industries continue to recognize these benefits, the adoption of LiFePO4 battery technology is expected to grow. Companies like Vedanta Aluminum and Johnson Controls are already leading the way, showcasing the practical benefits of switching to LiFePO4 battery systems. By investing in this advanced technology, businesses can enhance their performance, reduce costs, and contribute to a more sustainable future.