Series Vs Parallel Ultimate Wiring Guide in 2024

Table of Contents

- Series Vs Parallel Ultimate Wiring Guide in 2024

- What is Wiring in Series?

- What is Wiring in Parallel?

- Key Differences in Wiring Batteries Series vs Parallel

- Capacity Planning for Series and Parallel Battery Wiring

- Comparative Analysis of Series vs Parallel Battery Connections

- Feasibility of Combining Series and Parallel Wiring

- Effective Charging Strategies for Series vs Parallel

- Battery Longevity in Series Compared to Parallel

- Choosing the Right Setup for Series or Parallel

- Conclusive Insights on Series vs Parallel Battery Wiring

- Learn More About Battery

When using multiple batteries for a project, you have two configuration options – series and parallel wiring. Understanding the differences is important, as each setup has distinct advantages and applications. Wiring in series increases voltage, while parallel increases capacity. The choice depends on your needs – more power output, long runtime, combination of both or stepping up to higher voltages. This article explores series versus parallel connections, how many batteries you can wire in each array, and when to choose one method over the other.

What is Wiring in Series?

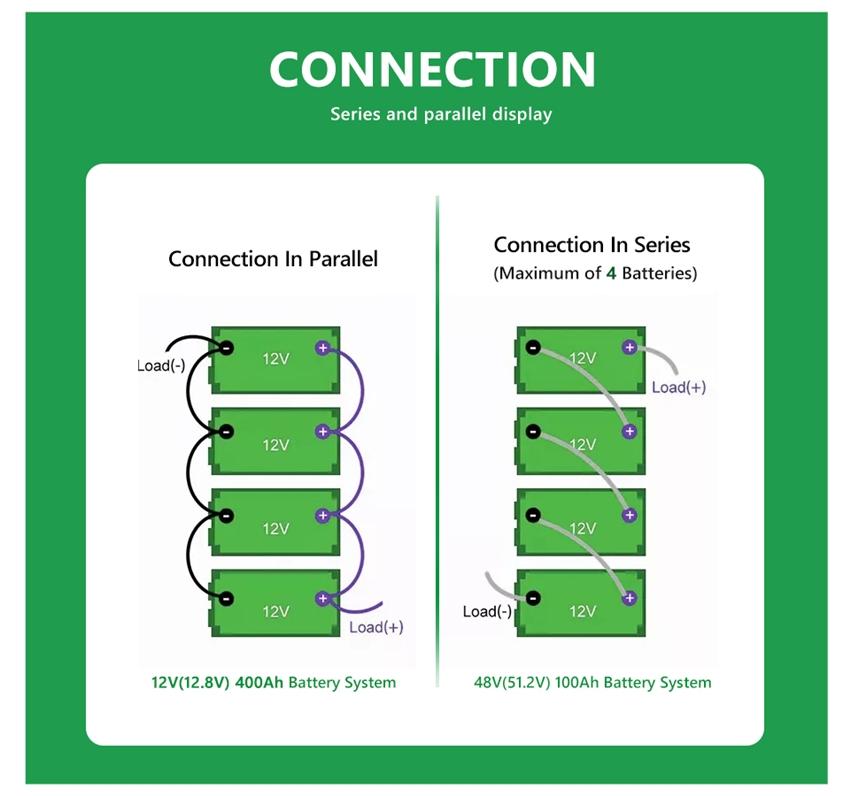

When wired, batteries in serial connect end-to-end with the positive terminal of one to the negative terminal of the next. This chains them together in a daisy-chain type configuration. Electron flow starts from the first battery’s negative, passes through each battery till exiting the last battery’s positive terminal.

Connecting batteries in serial like this sums their voltages, but capacity remains the same. For example, two 12V 100Ah batteries wired in series provides 24V with a capacity of 100Ah. Though they double the voltage, total run time is unchanged compared to just one battery.

Key advantages of series wiring are increased voltage along with the ability to construct high voltage sources from multiple lower voltage cells. It allows using commonly available batteries to attain otherwise uncommon voltages for specialized devices. Series battery banks also retain the same capacity at higher voltages. But the current ability is still limited to what a single battery can provide.

What is Wiring in Parallel?

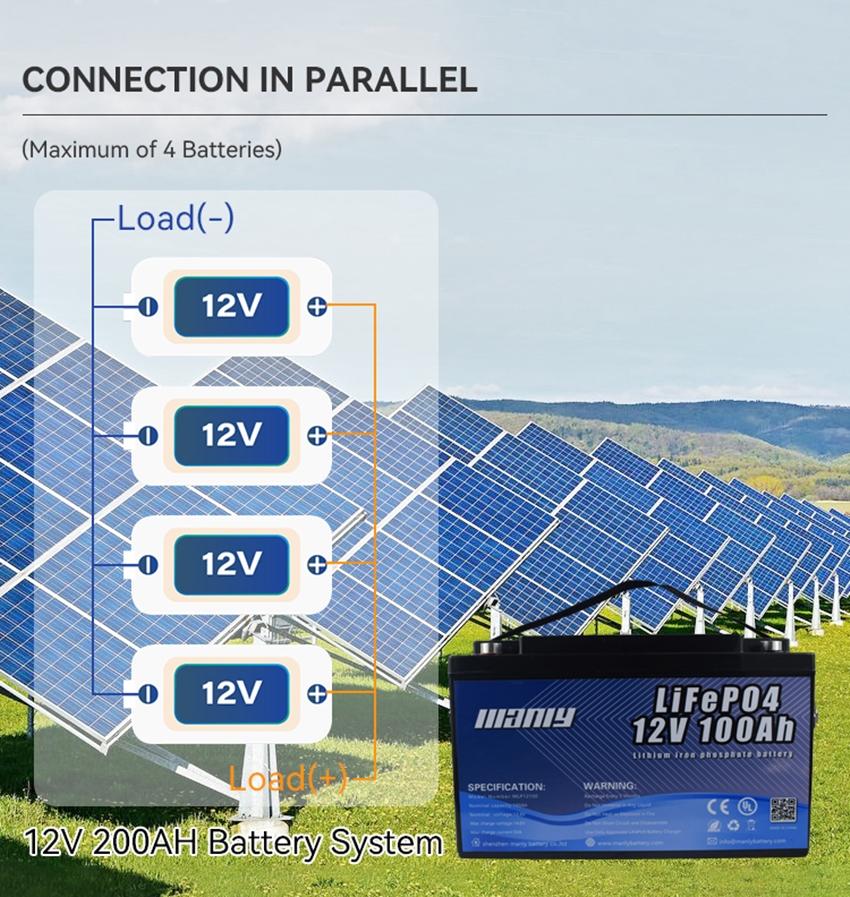

On the other hand, batteries in parallel connect side-by-side – positive terminals to positive, negative terminals to negative. This keeps voltages identical but sums the capacities. Sticking with the above example, two 12V 100Ah batteries in parallel maintain 12V but gain 200Ah of capacity. Though voltage is unchanged, they double runtime compared to a single battery.

Batteries in parallel enable higher currents to be drawn versus a single cell. This helps when more power output is needed. The batteries essentially behave like one large battery but with increased continuous current ability. With cables appropriately sized, parallel banks also have redundancy – if one battery fails the system still works at reduced capacity.

Key advantages of parallel wiring are increased capacity and current output while maintaining the same system voltage. But the voltage itself remains the same as a single battery.

Key Differences in Wiring Batteries Series vs Parallel

Series and parallel are the two basic ways batteries can be interconnected. The configuration impacts characteristics like voltage, capacity and discharge rate:

- Voltage – When batteries are wired in series, their voltages add up. For example, connecting two 12V batteries in series results in 24V. In parallel, the voltage stays the same (e.g. two 12V batteries connected in parallel still provide 12V).

- Capacity – Wiring batteries in parallel increases the capacity and ability to provide more current/power for longer periods of time. Putting batteries in series does not increase capacity over a single battery.

- Failure tolerance – Paralleled batteries provide some failure tolerance. If one battery dies, current keeps flowing through the other one. With batteries in series, if one battery dies or is disconnected, the circuit is broken, and everything stops working.

- Cost – Wiring batteries in series costs less because fewer batteries are needed to achieve higher voltages. However, there is less redundancy. Parallel-wired batteries provide redundancy and backup power if an individual battery fails but require more individual batteries.

- Safety – There are some safety advantages wiring batteries in series vs parallel. If a parallel string of batteries shorts out, a huge amount of current can flow, creating hazard. With series batteries, the current flow would be more limited by battery internal resistance. However, shorting out batteries in series can be dangerous in different ways.

- Complexity – Parallel battery configurations are more complex to build, requiring more connection points and cabling. Series arrangements are simpler. However, parallel setups provide monitoring/management at the individual battery level.

- Applications – Series arrangements are commonly used when higher voltages are needed from lower voltage batteries. Parallel configurations are used when redundant backup time or capacity is critical, the system can operate on lower voltages, space is limited, or expandability is desired.

So in summary – series connections boost voltage, while parallel connections boost capacity and redundancy. Complexity, failure tolerance, and safety also differ. Understanding these differences allows correct battery arrangements for an application’s specific voltage and current needs.

Capacity Planning for Series and Parallel Battery Wiring

1. Series Battery Limitations

There is no strict limit to how many batteries you can wire together in series. You can keep adding cells in chains to increase voltages. But higher voltages require safety precautions along with compatibility checks with connected equipment.

Too low or too high input voltage can harm appliances and electronics. So, series banks interconnected to gadgets or chargers should observe voltage limitations as per manufacturer recommendations. For longevity concerns, optimal operating voltages give best results.

Extremely high DC voltages also warrant isolation, protection circuits, insulation and physical barriers – especially when human contact is probable. Still, with appropriate safety measures very high voltage DC sources can be constructed safely.

There are also chemical constraints – excessively charging lead acid or lithium batteries stresses internal components. So practical limits depend on the battery chemistry and construction. 100-150V is common for flooded lead acid batteries and 60V or less for sealed lead acid. 500V works for Li-ion packs. Beyond these requires specialized cell designs and safety mechanisms.

2. Parallel Battery Limitations

Compared to series connections, paralleling has more defined limitations for maximum batteries due to physical constraints. As current capability increases, extremely heavy gauge wires become necessary to connect the batteries without losses. Connector ratings, insulation ratings and surrounding protections also demand upgrades.

Standard battery interconnects can safely join up to 4 to 8 like-capacity 12V batteries in parallel depending on the expected loads. Higher counts require cables that can handle bolted connections along with higher capacity disconnect switches and fuses. These ensure safe connections and prevent issues like short circuits from propagating through the entire bank.

There are also electrical constraints – slight differences in state of charge or internal resistance causes less charged batteries to get dragged down further. This accelerates sulphation and deterioration in some members, causing imbalance. Periodic equalization charges can mitigate this issue and extend operational life.

With large enough cables and protection gear more batteries can be paralleled. But 8 to 12 batteries are a common parallel connection limit for manageable DIY off-grid solar and backup power setups. Commercial installations go into 100s with proper design.

Comparative Analysis of Series vs Parallel Battery Connections

When wiring batteries together, you have two main options – connecting them in series or in parallel. Each configuration has its own advantages and limitations in terms of voltage, capacity, and safety considerations. Understanding these factors is key to designing effective battery packs.

1. Series Connections

When batteries are wired in series, their voltages add up, but their capacity remains the same. For example, connecting two 12V batteries in series produces 24V with the same capacity (amp-hour rating) as a single 12V battery. This increases the output voltage while maintaining the same charge capacity.

You can keep adding more batteries in series to increase the voltage – three 12V batteries wired in series produces 36V, four produces 48V, and so on. However, there are practical limits to how many batteries you can safely connect this way before hitting dangerous voltage levels. Excess heat can also become an issue.

As a rule of thumb, it’s not recommended to exceed 48V for consumer DIY projects using common lead-acid or lithium batteries. Commercially built equipment may use higher voltage battery packs safely, but home projects should avoid hazardous high voltage levels.

2. Parallel Connections

Wiring batteries in parallel keeps the voltage the same but adds up the capacities. For example, two 12V 10Ah batteries connected in parallel maintain 12V but can deliver 20Ah total. This provides longer runtime by combining the available stored charge, but the voltage stays the same.

When wired in parallel, there is less concern about over-voltage issues or heat buildup. Instead, the limiting factor becomes physical space and cabling practicalities. There is no strict upper limit, but you can only fit so many batteries in a given area. The copper wires must also be thick enough to handle the total expected load without excessive voltage drop or overheating.

3. Series-Parallel Arrays

For many home and commercial projects, the ideal configuration is a series-parallel array that combines the voltage increase of series wiring with the capacity benefits of parallel sets.

For example, four 12V 10Ah batteries could be arranged as two series strings of 24V 10Ah, then wired in parallel to create a 24V 20Ah pack. This delivers decent voltage and capacity in a compact arrangement.

Larger arrays are common for electric vehicles, solar storage banks, and other applications requiring high power and capacity. Practical limits relate to physical size, cost, and the ability of the charging/monitoring systems to handle the battery array.

In summary, understanding series vs parallel wiring is key to building safe and effective battery packs. While there are no absolute limits, excessive voltage or unwieldy arrays should be avoided for consumer-level projects. Careful planning of the battery configuration based on your voltage and capacity requirements will lead to the best and safest outcome.

Feasibility of Combining Series and Parallel Wiring

Yes, batteries can be arranged in both series and parallel in combined networks. Such configurations allow constructs combining the voltage gains of series strings with the capacity and current capabilities of parallel groups.

Batteries first interconnect in series till the desired system voltage is reached. Then these series strings get paralleled together to add capacities. This flexible arrangement forms versatile high voltage, high capacity battery banks.

For example, four 12V 100Ah batteries can series-parallel in two ways:

- Two strings of 2 series batteries, with 24V 100Ah each, paralleled for a 24V, 200Ah bank.

- Four batteries in series first making a 48V, 100Ah string. Then paralleled with another identical 48V, 100Ah series string to create a 48V, 200Ah bank.

The first method has half the voltage for the same capacity verses the second one. But both demonstrate combined series-parallel configurations for different voltage/capacity targets.

Such arrangements need matching batteries – same model, chemistry, age and state of charge. Mismatched cells strain weaker ones leading to rapid wear, risking bank failure. Matched cells ensure balanced currents across each series segment and parallel branch.

Cabling considerations are also vital when series-paralleling. Parallel connections need properly rated cables for cumulative current capacity. Series links between parallel groups should adequately insulate higher voltages while carrying full current.

Though more complex, flexible series+parallel topologies allow battery banks tailored to specific electrical needs. Cells sized for the job can wire for uncommon voltages not available in commercial offerings. Used judiciously, custom banks get designed for voltage as well as current/capacity needs.

Effective Charging Strategies for Series vs Parallel

Charging methodology also changes for series versus parallel wired banks:

1. Series Charging

When batteries series-connect, their voltages add but capacity stays the same. This means during charging each battery receives the same current but sees a voltage proportional to its position in the chain.

For example, with three 12V batteries in series, each battery receives the same charge current. But the first battery sees 12V across its terminals. The second gets 24V dropping across it. The third experiences the full 36V of the bank.

So, a series string charges most efficiently when all batteries are closely matched – same design, chemistry, age and state of charge. Mismatched cells lead to uneven charging and accelerated deterioration of weaker units.

Chargers for series banks should be variable voltage types allowing adjustment as needed. Maximum voltage gets set just above the total series voltage to account for resistance losses. Current gets set per what the battery bank can accept. Careful voltage control across individual cells while charging is also critical – differences strain batteries.

2. Parallel Charging

In parallel wiring, batteries present identical voltages to the charger but cumulative capacity. By connecting positive-to-positive and negative–to-negative in parallel arrays, each battery sees the same voltage drop across its terminals.

So, when charging, the source applies common charging voltage for the battery type and each cell receives current as needed. Voltage remains fixed, only output current capacity goes up to match the combined parallel capacity. This makes charging simpler and faster, though a larger charger is essential.

Cost savings also occur – one appropriately sized charger suffices instead of multiple smaller units. Parallel groups work well when batteries are reasonably balanced. Weaker members receive current preferentially until they equalize with stronger ones during each charge cycle.

Battery Longevity in Series Compared to Parallel

Battery life primarily depends on:

- Charge/discharge depths

- Charge voltages

- Operating temperatures

- Maintenance

Series versus parallel wiring by itself does not directly dictate lifespan. But differences in charging and discharging behavior under the two configurations have secondary impacts.

1. Series Life Expectancy

Under series conditions, batteries see the same current but divide voltage drops. So, cells are constrained to cycle together irrespective of individual health and capacities. A weak battery gets no rest while a stronger one operates below capacity.

Uneven charging also strains weaker cells in series strings by elevating internal temperatures and pressures. Premature failure of just one battery affects the whole chain. Replacement also requires matching specifications.

These factors indirectly diminish overall lifespan and performance over years unless charging voltages are carefully regulated. Allowing batteries to drift apart risks system breakdowns, fire or explosions.

2. Parallel Life Expectancy

In parallel wiring, each battery handles just a fraction of the current load proportional to its internal resistance and voltage. Individual cells cycle relatively independently so weaker ones aren’t dragged down harshly by healthier teammates.

Voltage matching is also less critical during charging/discharging since stresses are lowest across individual batteries. Differences just result in slightly uneven currents distributed based on cell conditions. Banks can utilize batteries of different capacities and ages with less tensions or cell failures.

These gentler operating characteristics indirectly extend average cumulative lifespan for the bank. Incremental swapping out older batteries is also easier without strictly matching replacements.

3. Best Practices For Durability

To maximize longevity for either series or parallel banks:

- Use voltage regulated smart chargers with proper bulk, absorption and float settings

- Prevent excess heat buildup during charging/discharging

- Maintain fluid/electrolyte levels in wet cell batteries

- Equalize periodically to avoid electrolyte imbalances

- Recharge fully after each cycle avoiding prolonged deep discharges

Following these best practices keeps all batteries in good operating health for years, irrespective of connections.

Choosing the Right Setup for Series or Parallel

Deciding between series and parallel battery connections depends on your specific power needs:

1. Higher Voltage

Series wiring is best when you need to reach higher voltages not attainable from available individual batteries. Chaining 12V batteries in series steps up to 24V, 36V and so on. This allows custom high voltage banks from commonly available cells.

Limited current capacity along with charging complexities are tradeoffs. But for applications like powering LED lighting, specialty motors etc., series battery builds offer a cost-effective way to get unconventional voltages.

2. Higher Capacity and Current

When operating or cycle time is important, parallel connections extend run duration. Amp-hour capacity sums when batteries capacity-couple in parallel. This proves advantageous for applications like off-grid solar storage, EV range extension etc. needing longer runtimes from a charge.

The bank also sees reduced impedance, enabling higher current draws to power hungry inverters, motor accelerations etc. Voltage remains fixed at the level of a single battery, just capacity and current scale up.

3. Best of Both

For extensive battery banks requiring high voltage as well as capacity over 1000Ah, combining series and parallel arrangements work best.

Batteries first series-connect in strings until target voltage nears. These chains then parallel together for aggregated amp-hours. This flexible topology allows large UPS and backup power banks tailored to both voltage and runtime needs.

4. Series-Parallel Drawbacks

Interconnecting batteries in complex series+parallel combinations seem an obvious win. But the approach is not without shortcomings.

Issues like charge imbalance, cell drift become more likely needing additional monitoring/maintenance. Expanded battery arrays also prove costlier requiring beefier cabling, enclosures and safety mechanisms. Losing just one battery crashes entire groups.

So, for smaller setups, opt for all-series or all-parallel. Mixed topologies best suit large expansive battery rooms with dedicated management systems.

In summary, factor in your voltage, capacity and redundancy needs. Series suits voltage expansion, parallel for capacity growth. While combined approaches meet specialized projects, simpler wiring often suffices smaller setups. Size cables safely, provide ample ventilation and don’t overlook protection circuits.

Conclusive Insights on Series vs Parallel Battery Wiring

Connecting batteries effectively requires understanding series, parallel and hybrid configurations. Each topology has specific benefits and drawbacks best suited to different applications. Wiring cells to meet project needs, within safe limits, leads to successful battery banks.

Series wiring concatenates cells for ascending voltages but fixed capacity. This suits LED strips, specialty motors and attaining uncommon voltages from readily available batteries. Charging requires voltage regulation for balanced currents across series members.

Parallel wiring bonds batteries for increased capacity and current, at the cost of same voltage as a single battery. Larger but lower voltage setups behave ideally for solar storage, EV ranges and high current devices via paralleled power sources. Charging occurs at a common voltage with capacity adding up.

Finally, hybrid series-parallel interconnections combine voltage steps-up with capacity sums in custom matrices. Hobbyist stacks gain flexibility while large UPS banks act as saleable high V, high Ah sources. Drawbacks like multiple points of failure demand close monitoring.

By interlinking cells methodically within operational ratings, versatile battery banks get engineered for specific needs. So, characterize your voltage, current, capacity and redundancy aim then series, parallelize or sequence-couple cells accordingly. Choose connection types to reach targets safely while maximize battery lifespans through sound maintenance practices regardless of topology.