Type of Forklift Battery: What Does a Forklift Use?

Table of Contents

Forklifts are essential machines in many industries, and the type of battery they use is crucial for their performance. Different types of forklift batteries offer unique advantages and disadvantages. This article will explore the characteristics, benefits, and maintenance requirements of various forklift batteries, including forklift lead acid battery, lithium ion forklift battery, and AGM forklift batteries. Understanding these differences can help businesses choose the best battery for their needs.(Get the best value with custom lithium ion forklift batteries from MANLY Battery. Click here to contact us now!)

Types of Forklift Batteries: Lead-Acid Batteries

Forklift lead acid battery is the most common type of battery used in forklifts. These batteries are also known as wet-cell batteries because they use a liquid electrolyte made of water and sulfuric acid. The basic components of a forklift lead acid battery include a battery case, cells, cables, and the sulfuric acid-water mixture.

Characteristics of Lead-Acid Batteries

Forklift lead acid battery is popular due to its relatively low cost. These batteries can last up to five years or more with proper maintenance. They are quite heavy, which can add to the overall weight of the forklift, making it less efficient in some scenarios. Another characteristic is the slow charging time; it typically takes about 8-12 hours to fully charge these batteries. This can be a significant limitation for operations that require quick turnaround times and continuous use of forklifts.

Pros and Cons

One of the main advantages of forklift lead acid battery is affordability. This makes it a common choice for businesses aiming to reduce costs while still ensuring reliable performance. However, there are several drawbacks:

- Weight: The heavy nature of these batteries can reduce the efficiency of the forklift.

- Charging Time: Slow charging (8-12 hours) can hinder operations that need rapid battery turnover.

- Cycle Life: These batteries have a shorter cycle life compared to other types, meaning they may need to be replaced more frequently.

Maintenance of Forklift Lead Acid Batteries

Proper maintenance is crucial for the performance and longevity of a forklift lead acid battery.

Regular Checks and Cleaning

Regularly checking and cleaning the battery is essential. The battery should be kept clean and free from dirt and grime. Inspections should focus on identifying any potential issues such as damage to the battery case or cables.

Electrolyte Levels

The sulfuric acid-water mixture, or electrolyte, must be maintained at proper levels. A forklift battery watering system can help keep the electrolyte levels accurate. It’s important to check that the electrolyte density is within the range of 1.28±0.01g/cm³. This ensures the battery functions efficiently and has a longer lifespan.

Proper Charging Practices

Using the correct charger for forklift lead acid battery is vital. Overcharging can lead to overheating, while undercharging can result in insufficient power. Both can reduce the battery’s lifespan. Following the manufacturer’s guidelines for charging is essential. It is also important to avoid overcharging and deep discharging. Overcharging can cause the battery to overheat and damage its internal components, while deep discharging can significantly reduce its lifespan.

Safe Storage

Store the battery in a cool and dry place. High temperatures can cause the battery to overheat and suffer thermal runaway, leading to damage. Ensuring the battery is kept in a well-ventilated area helps maintain its health.

In conclusion, while forklift lead acid battery offers affordability and reliability, it requires diligent maintenance and careful handling to maximize its benefits and lifespan. Regular checks, proper charging practices, and maintaining electrolyte levels are key to ensuring these batteries perform efficiently over time.

Other Types of Forklift Batteries

Gel Cell Forklift Batteries

Gel cell forklift batteries are a type of forklift lead acid battery that require less maintenance than traditional wet-cell batteries. They use a gel electrolyte mixture, which is achieved by adding silica to the sulfuric acid, creating a thick, gel-like substance. This thickened electrolyte means that gel cell forklift batteries can be installed in various positions without leaking or emitting fumes.

One of the main advantages of gel cell forklift batteries is that they are sealed and do not require a forklift battery watering system. This makes them easier to maintain and safer to use, as there is no risk of acid spills. However, charging these batteries requires special attention. The charging process is slower, and it is crucial to remove the battery from the charger as soon as it is fully charged. Leaving a gel cell forklift battery on the charger can cause voids in the electrolyte, leading to irreversible damage.

Gel cell forklift batteries are less affected by extreme vibrations and shocks, making them ideal for rough environments. They are particularly suitable for applications where the forklift may be subject to frequent jolts and impacts.

Nickel-Cadmium Forklift Batteries

Nickel-cadmium forklift batteries are known for their reliability and long life. These batteries can achieve over 8000 cycles, making them a durable choice. They also have a high energy density and can deliver a strong power output, which allows for quick charging and consistent performance. However, nickel-cadmium forklift batteries are more expensive and heavier compared to other battery types. The use of cadmium also raises environmental concerns, making them less attractive for companies focusing on sustainability. Additionally, while nickel-cadmium forklift batteries have minimal degradation, between zero and 2%, they still pose a greater environmental risk.

Nickel-Metal Hydride Forklift Batteries

Nickel-metal hydride forklift batteries are a newer type of battery used in high-end, large forklifts. These batteries are more environmentally friendly compared to nickel-cadmium forklift batteries and offer a higher energy density and longer lifespan than forklift lead acid battery. They are also efficient and have a short charging time, making them suitable for high-frequency use.

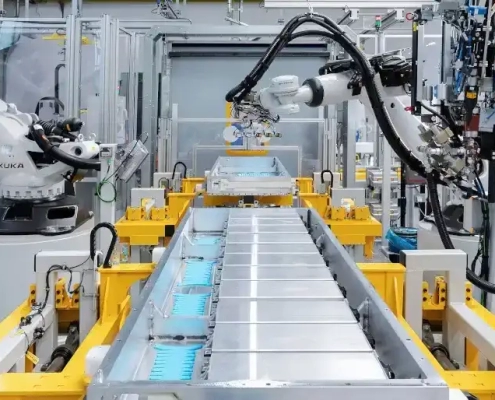

However, nickel-metal hydride forklift batteries come with a higher cost and require a specialized battery management system to achieve optimal performance. They are ideal for scenarios that demand long continuous use, such as in manufacturing and logistics operations.

Conclusion

In conclusion, selecting the right type of forklift battery depends on the specific needs and operational conditions of your business. Forklift lead acid batteries are cost-effective and reliable but require regular maintenance. Lithium ion forklift batteries offer high energy density, long lifespan, and low maintenance, making them ideal for high-demand environments. AGM forklift batteries provide a low-maintenance option that is safe and stable. By considering the pros and cons of each type, you can ensure that your forklifts operate efficiently and effectively, enhancing overall productivity and reducing downtime.