Unlocking Battery Cell Stack: The Future Tech

Table of Contents

Exploring a Decade of Lithium Battery Advancements: What's New?

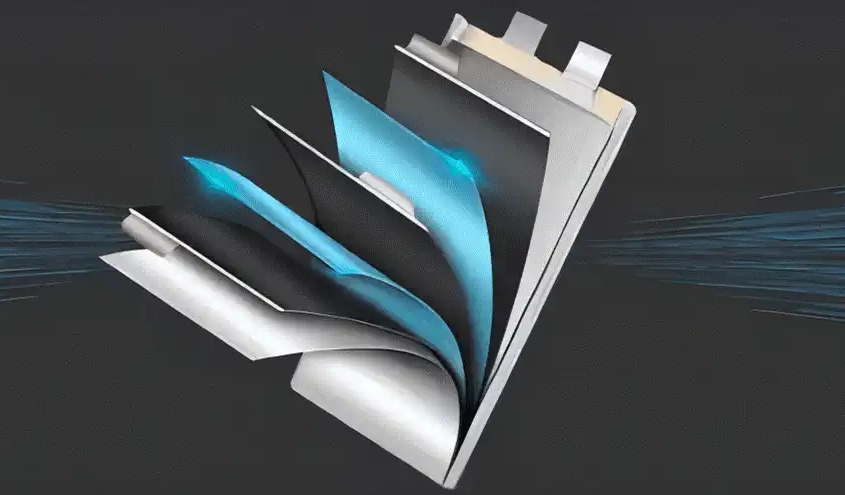

Over the past ten years, the lithium battery industry has grown rapidly with huge jumps in production. However, there haven't been many groundbreaking advancements in lithium battery technology. When it comes to materials, we still mostly see iron phosphate and ternary systems. As for the design, square, cylindrical, and pouch designs dominate. The main challenge with lithium battery innovation is balancing several factors. These include cost, safety, energy density, the number of charge cycles, temperature performance, and even ensuring there are enough resources. Despite these challenges, the lithium battery sector has explored various new ideas in recent years. These include cobalt-free materials, high-nickel systems, solid-state designs, composite flow bodies, iron manganese phosphate, and even sodium-ion batteries that don't rely on lithium. As for structure, innovations include shorter blades, blade designs, large 4680 cylinders, and high-speed battery cell stack methods. Given the existing mature material and structural systems, which technological direction stands out the most from an industrialization, penetration, and industry impact perspective? Which can be called the second major technological path?