EV Battery Recycling Market Growth

Table of Contents

As China’s electric vehicle (EV) industry grows, so does the ev battery recycling market. According to the China Society of Automotive Engineers, over 580,000 tons of EV batteries were retired in China in 2023. By 2030, the ev battery recycling market is expected to exceed 100 billion yuan.

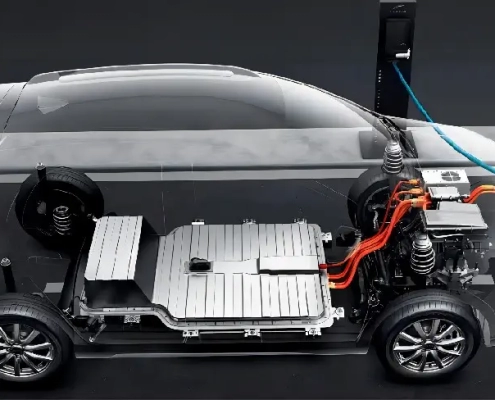

EV batteries account for about 50% of carbon emissions during the production phase of electric vehicles. Building a robust ev battery recycling system is crucial. It will enhance resource efficiency and reduce the overall carbon footprint throughout the batteries’ lifecycle.

The Importance of Battery Recycling

By the end of 2023, China had 20.41 million electric vehicles. As more EVs hit the road, battery recycle efforts are growing each year. When an EV battery’s capacity falls below 70-80%, it needs to be replaced. Last year, the number of retired batteries increased by over 140%, marking a new growth phase for the battery recycle industry.

After recycling, batteries are reused based on their remaining capacity. If a battery has 60-80% capacity left, it can be used in electric forklifts, two-wheel electric vehicles, and large energy storage stations. Batteries with 20-60% capacity are suitable for small energy storage stations, telecom base stations, and solar energy storage systems. Batteries with less than 20% capacity are dismantled to extract valuable metals for reuse.

This process helps recover precious resources like lithium, nickel, cobalt, and manganese. Enhanced battery recycle efforts can meet 20% of China’s lithium needs, 11% of nickel, and 25% of cobalt for new EVs each year, reducing dependence on imported raw materials.

EV Battery Recycling Market to Exceed 100 Billion Yuan by 2030

As China’s electric vehicle (EV) industry grows, so does the ev battery recycling market. According to the China Society of Automotive Engineers, over 580,000 tons of EV batteries were retired in China in 2023. By 2030, the ev battery recycling market is expected to exceed 100 billion yuan.

EV batteries account for about 50% of carbon emissions during the production phase of electric vehicles. Building a robust ev battery recycling system is crucial. It will enhance resource efficiency and reduce the overall carbon footprint throughout the batteries’ lifecycle.

Battery Recycle: Solving Resource Issues

By the end of 2023, China had 20.41 million electric vehicles. As more EVs hit the road, battery recycle efforts are growing each year. When an EV battery’s capacity falls below 70-80%, it needs to be replaced. Last year, the number of retired batteries increased by over 140%, marking a new growth phase for the battery recycle industry.

After recycling, batteries are reused based on their remaining capacity. If a battery has 60-80% capacity left, it can be used in electric forklifts, two-wheel electric vehicles, and large energy storage stations. Batteries with 20-60% capacity are suitable for small energy storage stations, telecom base stations, and solar energy storage systems. Batteries with less than 20% capacity are dismantled to extract valuable metals for reuse.

This process helps recover precious resources like lithium, nickel, cobalt, and manganese. Enhanced battery recycle efforts can meet 20% of China’s lithium needs, 11% of nickel, and 25% of cobalt for new EVs each year, reducing dependence on imported raw materials.