What Effects the Total Cost of Your Forklift Battery?

Understanding the factors that affect the total cost of your lithium ion forklift battery can help you make more informed decisions. Here, we will break down the key elements that contribute to the total cost of ownership (TCO) of forklift batteries.

Retail Price

The initial retail price is the most noticeable cost. While lithium ion forklift batteries often have a higher upfront cost compared to traditional lead-acid batteries, this higher initial investment is offset by their numerous long-term benefits. For instance, the initial cost of a lithium ion battery can be two to three times that of a lead-acid battery, but this is just the beginning of the cost analysis.

Installation Costs

Installation costs are typically a nominal part of the overall expense. This usually involves a skilled technician installing the battery, a process that is necessary for both types of batteries. However, while lead-acid batteries may require multiple installations over their lifespan due to shorter battery life, a single installation of a lithium ion forklift battery often suffices for many years, reducing repetitive installation costs.

Maintenance Costs

Maintenance is a significant factor in the TCO. Lead-acid batteries require regular maintenance, including checking and topping off water levels, cleaning acid residue, and replacing corroded parts. These maintenance tasks are time-consuming and can lead to additional downtime and labor costs. In contrast, lithium ion forklift batteries are virtually maintenance-free, eliminating these routine checks and the associated costs.

Charging Time and Energy Costs

Lithium ion forklift batteries offer the advantage of much shorter charging times compared to lead-acid batteries. A lead-acid battery typically takes about 8 hours to fully charge, whereas a lithium ion battery can be charged in just over an hour. This rapid charging capability reduces downtime and can significantly enhance productivity. Additionally, lithium ion batteries are more energy-efficient, converting up to 98% of the energy from the charger into usable power compared to around 80% for lead-acid batteries. This higher efficiency means lower electricity costs over the battery’s life.

Battery Replacements

The replacement cycle is another critical cost factor. Lead-acid batteries generally last between 500 to 1,000 cycles, meaning they need to be replaced more frequently. On the other hand, lithium ion forklift batteries can last up to 3,000 cycles or more, dramatically reducing the frequency and cost of replacements.

Infrastructure Costs

Lead-acid batteries require significant infrastructure investments, such as dedicated charging stations with ventilation to handle gas emissions, special flooring, and safety equipment like eye wash stations and emergency showers. Lithium ion forklift batteries, being sealed units, do not require such extensive safety measures, leading to lower infrastructure costs.

Productivity Impact

With lithium ion forklift batteries, the lower impedance and shorter charging times lead to reduced downtime and higher productivity. These batteries can be charged during short breaks without affecting the battery’s lifespan, unlike lead-acid batteries, which need a full charging cycle. This enhanced productivity can result in significant cost savings, especially in multi-shift operations.

Environmental Impact

Lithium ion batteries are more environmentally friendly compared to lead-acid batteries. They have a longer lifespan, require less energy to charge, and do not contain harmful lead. This makes them a more sustainable choice, aligning with global trends towards eco-friendly practices and potentially reducing waste disposal costs.

The total cost of ownership for each battery type can be summarized as follows (indicated by dollar signs for cost levels, with more dollar signs representing higher costs):

| Cost Factor | FLA | AGM | GEL | Lithium Ion |

|---|---|---|---|---|

| Purchase Cost | $$ | $$$ | $$$ | $$$$ |

| Installation Cost | $$ | $$ | $$ | $$ |

| Maintenance Cost | $$$$ | $$$ | $$$ | $ |

| Charging Cost | $$$ | $$ | $$ | $ |

| Replacement Cost | $$$$ | $$$ | $$$$ | $ |

| Replacement Labor | $$$ | $$ | $$ | $ |

| Number of Replacements | $$$$ | $$$ | $$$$ | $ |

| Cycle Life | $$ | $$$ | $$$ | $$$$ |

| Total Cost Over Life | $$$$ | $$$ | $$$$ | $$ |

Leading Manufacturers of Lithium Ion Forklift Batteries

When considering the top lithium ion battery manufacturers, five companies stand out: Crown Battery, East Penn Manufacturing, MANLY Battery, JB Battery and Hoppecke. These manufacturers have built strong reputations for their innovative products, commitment to quality, and robust production capabilities.

Hoppecke

Hoppecke, based in Brilon, Germany, has been producing batteries and related accessories for over 76 years. As a significant player in the lithium ion battery manufacturing industry, Hoppecke offers a wide range of products that meet the highest global standards.

Product Range and Quality Hoppecke manufactures various types of lead-acid batteries, VRLA (valve-regulated lead-acid) batteries, nickel-cadmium batteries, and the corresponding charging equipment. Their production adheres to German industrial standards (DIN) and has received ISO9001 and ISO14001 certifications from TUV, ensuring top-notch quality and reliability.

Applications and Technical Support Hoppecke’s batteries are used in multiple industries, including automotive and forklift applications. They provide comprehensive technical support and services to ensure their products deliver maximum value to customers. Notable clients like Mercedes Benz, Siemens, Linde, ABB, Adtranz, and Hyster rely on Hoppecke’s expertise and products.

Global Reach and Innovation With a focus on innovation, Hoppecke continues to expand its global presence. Their dedication to maintaining long-term business relationships and expanding their market reach underscores their commitment to customer satisfaction and industry leadership.

East Penn Manufacturing

East Penn Manufacturing, headquartered in Lyons, Pennsylvania, was founded in 1946 by DeLight Jr. This company has grown to operate the largest single-site lead-acid battery manufacturing facility in the world. East Penn is renowned for its Deka series of forklift batteries, chargers, services, and accessories.

East Penn’s Deka batteries are known for their high performance and reliability. The company’s dedication to innovation is evident in their products, including the Deka Fahrenheit VRLA battery systems, which come in 12-volt and 2-volt configurations. In 2023, East Penn Manufacturing reported an annual revenue of $1.8 billion, supported by a workforce of 7,500 employees. Each employee generates approximately $240,000 in revenue, highlighting the company’s efficiency and productivity.

MANLY Battery

MANLY Battery, a leading lithium battery manufacturer in China, has established itself as a premier lithium battery supplier with over 13 years of experience. Located in Shenzhen, Dongguan, and Huizhou, MANLY’s factories span a vast 65,000 square meters. Every day, MANLY’s production lines generate 6MWh of battery cells and assemble over 3,000 batteries. This impressive capacity reflects their dedication to both quantity and quality.

Versatile Product Offerings

MANLY Battery offers a wide range of LiFePO4 and lithium-ion batteries, from 6V to 72V, tailored for various applications. Their batteries are used in:

- Solar energy storage solutions

- Residential and industrial energy storage

- Advanced robotics, including military applications

- Base station support

- Solar street lighting

- Uninterruptible Power Supply (UPS) systems

Customization and Quality Assurance

MANLY prioritizes customization to meet specific client needs. They offer bespoke battery solutions, customizing voltage, capacity, and aesthetics. Their commitment to quality is evident through global certifications like UN38.3, IEC62133, UL, and CE. Additionally, MANLY batteries come with a decade-long warranty, ensuring long-term reliability and performance.

Safety and Performance

MANLY batteries feature advanced safety measures, including short circuit protection, overcharge safeguards, and overcurrent prevention. These batteries are designed to perform under harsh conditions, operating optimally between -20°C to 75°C (-4°F to 167°F). The efficiency of MANLY’s LiFePO4 batteries is remarkable, with an energy efficiency rate of 95%, far surpassing the 70% efficiency of traditional lead-acid batteries.

Innovative Features

To enhance user experience, MANLY batteries are equipped with modern features like Bluetooth connectivity and intuitive battery level displays. This blend of high performance, safety, and user-friendly features positions MANLY as a top lithium battery company.

Crown Battery

Crown Battery is a prominent lithium ion battery manufacturer known for producing a wide range of industrial batteries, including those used in forklifts, material handling equipment, and mining machinery. Founded in 1926, Crown Battery has built a reputation for reliability and performance. Their products are backed by a national network of sales and service locations, ensuring comprehensive support for customers.

Crown Battery’s offerings include not only batteries but also a variety of chargers, fast chargers, and related accessories. This complete product line ensures that customers can find all the components they need for their forklift battery systems in one place. Crown Battery’s commitment to quality and service has made them a trusted name in the industry.

GS Yuasa

GS Yuasa Corporation is a prominent lithium ion battery manufacturer based in Japan. With a long history of innovation and quality, GS Yuasa has established itself as a leader in the battery industry. The company operates in four main business segments: domestic automotive batteries, domestic industrial batteries and power supplies, overseas automotive batteries, and automotive lithium-ion batteries.

Product Range and Expertise

GS Yuasa produces a diverse range of batteries. Their product lineup includes batteries for cars and motorcycles, industrial alkaline stationary batteries, and advanced lithium-ion batteries for electric vehicles. This extensive product range ensures that they can meet various market needs, positioning them as a top lithium battery company.

Global Reach and Market Influence

Although more than half of GS Yuasa’s revenue comes from Japan, the company also has a significant presence in international markets. Recently, GS Yuasa announced the sale of a portion of its shares in two Chinese subsidiaries that manufacture and sell automotive lead-acid batteries. This strategic move, expected to be completed by September, involves selling 70% of the shares in Tianjin GS Battery and Yuasa Battery (Shunde) to Leoch Battery, a local player in the lead-acid battery market. Despite the sale, GS Yuasa plans to continue providing technical support to these companies, ensuring their products maintain high standards of quality and performance.

Financial Performance

For the fiscal year ending March 31, 2024, GS Yuasa reported group revenues of 562.9 billion yen and an operating profit of 41.6 billion yen. This strong financial performance underscores the company’s robust market position and its ability to deliver reliable battery solutions across various sectors.

Conclusion

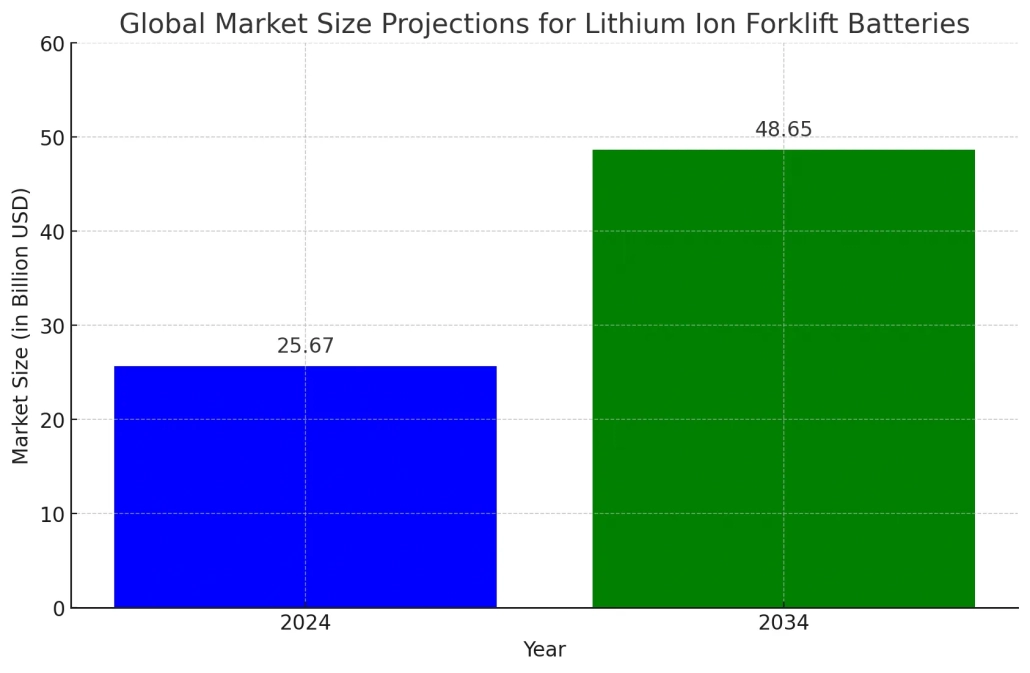

The shift towards lithium ion forklift batteries is driven by their clear advantages over traditional lead-acid batteries. With faster charging times, longer life cycles, and higher energy efficiency, these batteries offer significant operational and cost benefits. The global market for lithium ion forklift batteries is expanding rapidly, with projections indicating a near doubling of market value from $25.67 billion in 2024 to $48.65 billion by 2034. This growth is supported by the increasing adoption of electric forklifts in Europe and the robust manufacturing capabilities in China. As lithium ion battery manufacturers continue to innovate and improve battery technology, the demand for these advanced batteries is set to rise, solidifying their dominance in the market and driving the forklift industry towards a more sustainable future.