How Long To Charge a 12v Battery At 10 Amps

Table of Contents

- How Long To Charge a 12v Battery At 10 Amps

- Factors Affecting Charging Time

- Calculation of Charging Time

- The Steps To Charge a 12V Battery

- Practical Considerations

- Can You Speed Up Charging?

- Troubleshooting Common Battery Charging Issues

- Safety and Maintenance

- Conclusion

- FAQ

- Learn More About Battery

- SMC Global Power plans to deploy 1GW battery energy storage project in 2022

- Outstanding Solar Batteries Guide for Smart Homes of 2024

- Are Solar Batteries Worth It?

- How Long Do Solar Batteries Last?

- Solar Batteries: How Well Do They Work?

- Selecting the Right Solar Battery

- How Do you Test a Solar Battery Bank?

- How Much Do Solar Batteries Cost

- Best Solar Batteries

- Definition and Types of Agricultural Robots

- 1. Definition of agricultural robot:

- 2.How Are Robots Used in Agriculture

- 3. Types of Agricultural Robots:

- 4. Lithium Batteries for agricultural robots

- 5. Conclusion

Charging a 12V battery with a 10 amp battery charger might sound simple, but many factors can affect how long it actually takes. From battery size and health to temperature and charger efficiency, each detail plays a role in determining your total charge time. Whether you’re using a smart model from a china battery charger factory or a basic unit from your local store, understanding these variables can help you charge faster, safer, and smarter. This guide breaks down the math, best practices, and common issues so you can get the most out of your battery chargers every time.

Factors Affecting Charging Time

1. Battery Capacity (Ah)

Battery capacity, measured in amp-hours (Ah), represents how much electric charge a battery can hold. Simply put, the larger the capacity, the longer it takes to charge. For example, if you’re using a 10 amp battery charger to charge a 100Ah battery, it would take roughly 10 hours to reach a full charge. The basic formula is:

Charging Time (hours) = Battery Capacity (Ah) ÷ Charging Current (A)

So, if you’re charging a 20Ah battery at 10 amps, expect it to take about 2 hours. A 50Ah battery would need approximately 5 hours under the same conditions. This relationship remains consistent across various battery sizes, assuming the charger maintains a steady current throughout the process.

2. Charging Current (Amps)

The charging current is the amount of electrical current delivered to the battery, measured in amps. Higher currents can reduce charging time, but they also raise the risk of excess heat, which can damage internal components over time. That’s why using a charger with the right current output—like a 10 amp battery charger for mid-sized batteries—is essential. This balances faster charging with the safety and longevity of the battery. Always follow the recommendations provided by the battery charger manufacturer or the battery’s technical datasheet to prevent overheating or short cycling.

3. Efficiency of the Charging Process

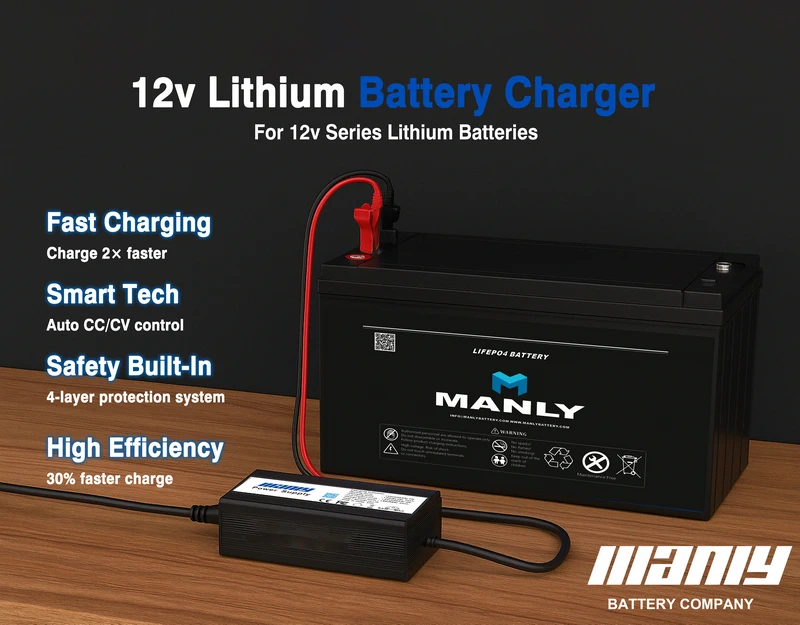

Not all the energy you feed into a battery gets stored—some is lost, usually as heat. Charging efficiency refers to the proportion of input energy that the battery can actually retain. For example, if a battery’s charging efficiency is 90%, then 10% of the energy is lost in the process. This means the actual time to charge may be longer than the theoretical value. Lithium-ion batteries, especially those produced by top china smart battery charger suppliers, generally boast higher efficiency levels (up to 95%) compared to traditional lead-acid types, which can drop below 85%. The type of charger also matters—china 12v lithium battery charger models are often optimized for better efficiency and heat management.

4. Importance of Battery Health

Battery health is a major factor in determining how long charging will take. As batteries age or experience repeated deep discharges, their internal resistance increases, slowing down the charging process. Environmental conditions—like extreme heat or freezing cold—can also reduce a battery’s ability to accept and hold a charge. A degraded battery might never fully charge or may take significantly longer than expected. To maintain performance, avoid exposing the battery to harsh temperatures and refrain from letting it discharge completely. Consistent maintenance not only helps preserve capacity but also ensures reliable operation with battery chargers of all types, including those from a china battery charger factory.

Calculation of Charging Time

Example Calculation

To determine how long it takes to fully charge a battery, you can start with a basic formula:

Charging Time (hours) = Battery Capacity (Ah) ÷ Charging Current (A)

Let’s break it down with a practical example. Suppose you’re charging a 100Ah battery using a 10 amp battery charger. The estimated charging time would be:

100Ah ÷ 10A = 10 hours

This calculation assumes perfect charging conditions—specifically, 100% efficiency. But in real-world applications, charging isn’t that flawless. Energy is lost in the form of heat, and actual charging efficiency usually ranges between 80% and 95%, depending on the battery chemistry and the quality of the charger.

To get a more accurate estimate, you should factor in charging efficiency. The revised formula looks like this:

Charging Time = Battery Capacity (Ah) ÷ (Charging Current (A) × Charging Efficiency)

Let’s say the efficiency is 85% (or 0.85 as a decimal). Using the same 100Ah battery and 10 amp battery charger, the calculation becomes:

Charging Time = 100Ah ÷ (10A × 0.85) ≈ 11.76 hours

So, instead of 10 hours, it would actually take nearly 11.8 hours to fully charge the battery under normal efficiency conditions. This adjustment reflects the typical loss that occurs during the conversion of AC power to stored DC energy inside the battery.

These formulas are especially helpful when selecting chargers from a battery charger manufacturer or comparing models from a china battery charger factory. Whether you’re choosing a basic china battery charger or a high-performance china smart battery charger, knowing how efficiency impacts charging time helps ensure you don’t undercharge or overwork your battery.

The Steps To Charge a 12V Battery

Charging a 12V battery correctly isn’t just about plugging in a charger—it’s a step-by-step process that helps you get the most out of your battery while keeping things safe. Whether you’re using basic battery chargers or a high-efficiency china smart battery charger, following the right steps ensures consistent performance and extends battery life.

1. Preparation

Ensure Proper Ventilation

Start by choosing a well-ventilated area. Charging a lead-acid or flooded 12V battery can release hydrogen gas, which is highly flammable. To reduce risk, make sure the area is free of open flames, sparks, or smoking.

Check Compatibility

Before connecting anything, confirm that your charger matches your battery’s voltage and chemistry. For example, a 12v battery manufacturer might require a charger tailored for lithium, AGM, or lead-acid cells. Using an incompatible charger may reduce battery performance or cause permanent damage.

Inspect All Equipment

Look over both the battery and the charger. If you see corrosion on the terminals or cracks in the casing, clean or replace the parts before proceeding. Chargers from reliable sources like a china battery charger factory are designed to reduce risk, but visual inspection is always the first line of safety.

2. Connecting the Charger

Attach the Positive Clamp

Take the red clamp from the charger and securely connect it to the battery’s positive terminal, marked with a “+” sign.

Attach the Negative Clamp

Then, connect the black clamp to the negative terminal, marked with a “–” sign. Always follow this sequence to minimize sparks and protect your gear.

3. Setting Charging Parameters

Adjust to the Right Settings

Set the charger to deliver the correct current. For medium-capacity batteries, a 10 amp battery charger offers a safe and efficient balance between charge time and heat generation.

Select the Proper Charging Mode

Modern china 12v lithium battery charger models often include selectable modes—standard, AGM, lithium, etc. Choose the one that aligns with your battery’s type to prevent overcharging or undercharging.

4. Initiating the Charging Process

Turn on the Charger

Once everything is securely connected and properly set, switch on the charger. If you’re using a smart charger from a trusted battery charger manufacturer, the device will likely auto-regulate voltage and current.

Monitor Charging Progress

Watch the status indicators or digital display if your charger includes one. Many china battery charger models provide real-time voltage or charge percentage, helping you track the process without guesswork.

5. Completing the Charge

Turn Off the Charger First

Before disconnecting anything, power down the charger completely. This step prevents electrical arcing and ensures a safe shutdown.

Disconnect Clamps in Reverse Order

Remove the black (negative) clamp first, then the red (positive) clamp. Reversing the connection sequence reduces the risk of a short circuit.

6. Post-Charging Checks

Verify the Voltage

Use a multimeter to confirm the battery is fully charged. A typical reading should be around 12.6 to 12.8 volts for most 12V lead-acid batteries at rest.

Tidy the Area

Once done, clean up the workspace. Remove tools, wipe down the charger, and store cables properly to keep your setup ready for the next use.

Practical Considerations

Impact of Temperature on Charging Time

Temperature plays a major role in how efficiently and safely a battery charges. Charging performance changes significantly depending on how hot or cold the environment is.

Cold Temperatures Slow Charging

When batteries are exposed to low temperatures—especially below 32°F (0°C)—their internal resistance increases. This makes it harder for ions to move within the cells, slowing down the charging process. For lithium-ion batteries in particular, cold conditions can cause lithium plating, which permanently reduces capacity and raises safety concerns. Studies from Battery University and others confirm that charging lithium-ion cells below freezing should be avoided whenever possible.

Heat Speeds Up Reactions—But Increases Risk

At higher temperatures, electrochemical reactions inside the battery accelerate. This may seem like an advantage for faster charging, but it comes at a cost. Excessive heat raises the chance of thermal runaway—a chain reaction where heat builds up uncontrollably, potentially causing the battery to swell, leak, or even ignite. Using china smart battery charger models with built-in temperature sensors can help manage these risks.

Best Practice: Charge at Room Temperature

For safety and efficiency, it’s best to charge batteries at moderate room temperature—around 77°F (25°C). This range supports stable electrochemical performance while minimizing stress on the battery materials.

Can You Speed Up Charging?

Yes—charging a battery faster is possible, but it comes with trade-offs. You can reduce charging time by increasing current, using fast-charging technology, and managing environmental conditions. However, rushing the process too often can shorten battery life. The key is to find the right balance between speed and longevity.

1. Use a Higher-Current Charger

The easiest way to speed up charging is to increase the current. For example, a 10 amp battery charger can fill a 100Ah battery in roughly 10 hours. By contrast, a 5 amp charger would double that time. The math is simple, but the safety isn’t—charging too fast with an incompatible charger can lead to overheating or battery damage.

Always check the battery’s rated maximum charge current, which is typically listed in the datasheet from your 12v battery manufacturer. Overloading the cells can reduce capacity over time or cause failure. Choosing a charger that matches your battery type and size—such as one from a trusted china battery charger factory—helps protect both speed and safety.

2. Utilize Fast-Charging Technologies

Fast-charging protocols like USB Power Delivery (PD) and Qualcomm Quick Charge (QC) are designed to increase power delivery without sacrificing safety. These systems dynamically adjust voltage and current based on real-time feedback between the charger and the device. For instance, Quick Charge 4.0 can push up to 27 watts, cutting down charge time significantly compared to traditional 5W outputs.

That said, the charger and the device must both support the same fast-charging standard. Using a china smart battery charger or a china 12v lithium battery charger that matches your battery’s chemistry—like LiFePO4 or NMC—is essential. Many advanced battery chargers also include protections for overvoltage, overcurrent, and thermal regulation to ensure charging stays efficient and safe.

3. Optimize Charging Environment

The temperature around your battery has a direct impact on how fast and efficiently it charges. Charging at room temperature—about 77°F (25°C)—allows batteries to perform optimally. When it’s too cold, internal resistance increases, slowing down the charging reaction. When it’s too hot, chemical activity speeds up—but so does battery degradation.

To get the most from your battery chargers, place them in a well-ventilated, shaded space away from heaters, direct sunlight, or cold drafts. Maintaining this temperature range helps chargers—especially high-performance units from a battery charger manufacturer—deliver consistent results without stressing the battery.

4. Consider Battery Health

While fast charging can be convenient, repeated exposure to high currents can cause additional heat buildup inside the cells. This can accelerate wear and reduce the total number of charge cycles a battery can handle. For long-term use, it’s wise to alternate fast charging with slower, controlled cycles.

Many smart chargers today include a battery health mode that limits current after a certain voltage threshold. If you regularly rely on fast charging, look for this feature in models from leading china battery charger suppliers to help extend battery life while still saving time when it counts.

Troubleshooting Common Battery Charging Issues

If your battery isn’t charging as expected, don’t panic. Many charging problems can be traced to common causes—and most can be fixed quickly once you know what to look for. Below, we walk through frequent charging issues and offer practical solutions to keep your battery chargers and batteries performing reliably.

1. Battery Not Charging

Potential Causes and Fixes:

Damaged Charger or Cable

Inspect the power cord and charging unit for signs of fraying, bent prongs, or overheating. Swap in another charger—ideally from a trusted battery charger manufacturer—to rule out hardware failure.Wrong Charger Type

Using the wrong charger can completely prevent charging. For example, a lithium battery requires a dedicated lithium battery charger—not just any generic model. Always verify that your charger matches your battery’s voltage and chemistry.Incorrect Terminal Connections

Check that the red (positive) and black (negative) leads are connected properly. Reversed clamps or loose terminals can disrupt the charging process or cause damage.Battery Management System (BMS) Lockout

Some batteries, especially lithium types, use a BMS that can temporarily shut off charging to protect the cells. If the system won’t reset, contact the 12v battery manufacturer or use a smart diagnostic charger designed for BMS-equipped batteries.

2. Slow Charging

Common Explanations:

Low Charging Current

If your charger supplies insufficient current, expect long charging times. Upgrading to a 10 amp battery charger, when suitable for your battery size, can significantly reduce charge duration.Battery Wear or Age

Older batteries or those that have been deeply discharged multiple times will typically charge more slowly. Run a capacity test if charging seems unusually sluggish.Temperature-Related Slowdown

Both hot and cold temperatures affect charging efficiency. Aim to charge batteries indoors at room temperature (around 77°F or 25°C) for optimal performance. Smart models from a china smart battery charger supplier can help regulate temperature automatically.

3. Charger Overheating

What to Watch For:

Prolonged High Output

Continuous operation at maximum output can cause a charger to overheat. If you’re running your charger for hours without breaks—especially near or above its rated capacity—consider taking cooling intervals or upgrading to a higher-rated unit from a china battery charger factory.Poor Airflow Around the Charger

Keep the charger in a well-ventilated, open space. Avoid covering it with objects or placing it near other heat sources.Exceeding Load Limits

Never exceed the amperage or voltage limits of your charger. Doing so may overwork the internal components and shorten the charger’s service life.

4. Battery Overheating

Primary Causes and Solutions:

Excessive Charging Current

Using a charger that exceeds your battery’s rated input current can cause internal cell temperatures to spike. Stick to the specs listed by your battery manufacturer and avoid using low-quality generic models.Hot Charging Environment

If you’re charging outdoors or in a garage during hot summer months, the ambient heat can compound internal temperature rise. Move your setup to a cooler, shaded, or climate-controlled location.Battery Degradation

Batteries naturally degrade over time. If a unit frequently overheats during charging—even under normal conditions—it may be time to replace it. Look for bulging, discoloration, or voltage drop under load as warning signs.

Safety and Maintenance

Maintaining your battery the right way isn’t just about performance—it’s also about safety. Consistent care and proper charging practices can extend battery life, reduce risks, and ensure your battery chargers operate efficiently without fail.

1. Avoiding Overcharging

Overcharging is one of the most common causes of battery damage. It leads to heat buildup, cell swelling, and a shortened lifespan.

Use Smart Chargers with Auto Shutoff

Smart charging devices—such as a MANLY 12v lithium battery charger—can automatically detect when your battery is full and stop charging to prevent overcharging. This feature protects the battery from stress and reduces the risk of overheating or fire.Set Charging Timers for Manual Chargers

If you’re using a charger without auto shutoff, calculate charging time using this formula:

Charging Time = Battery Capacity (Ah) ÷ Charging Current (A)

For example, a 100Ah battery paired with a 10 amp battery charger would require about 10 hours for a full charge. Be precise—leaving it connected too long can cause long-term damage.Avoid Overnight Charging

Don’t leave batteries on the charger for extended periods. Even with trickle charging, excess heat can build up and slowly degrade the battery over time. Unplug once charging is complete.

2. Monitoring the Charging Process

Monitoring the battery while it charges can help prevent small issues from turning into major failures.

Check for Warning Signs

Look for physical changes such as battery swelling, unusual smells, or heat from the charger. If you notice anything abnormal, stop charging immediately and reach out to the battery charger manufacturer or battery supplier.Charge in a Safe, Open Area

Avoid closed or cluttered spaces. A well-ventilated environment helps disperse heat and prevents potential fire hazards—especially critical when charging high-capacity units.Match the Charger to the Battery

Never mix incompatible gear. For instance, don’t use a lead-acid charger on a lithium-ion battery. Chargers from a reliable china battery charger factory are usually labeled for specific chemistries and voltage levels—follow those specs.

3. Manufacturer Guidelines

Following official manufacturer instructions is more than just good practice—it ensures you get the performance and safety the product was designed for.

Read the Manuals

Always follow the charging instructions provided by your 12v battery manufacturer and the maker of your battery chargers. These documents explain ideal voltage ranges, compatible accessories, and safety precautions.Routine Maintenance

Clean terminals regularly to remove corrosion, which can interfere with electrical contact. Make sure connections are tight and check for physical wear on both battery and charger components. Routine checks can prevent issues before they start.Charge at Proper Temperatures

Avoid charging in extreme heat or cold. For most battery chemistries, room temperature—around 77°F (25°C)—is ideal. Charging outside this range can slow down the process and impact long-term capacity.

Conclusion

Knowing how long to charge a 12V battery at 10 amps isn’t just about plugging in a charger and walking away—it’s about using the right tools, understanding your battery’s specs, and managing environmental conditions. With the right battery charger manufacturer and a well-matched china smart battery charger, you can optimize both charging time and battery lifespan. Whether you’re maintaining backup power systems or just keeping your vehicles ready to go, following the right charging routine ensures safety, efficiency, and long-term reliability.

FAQ

1. Is 10 amps too much to charge a car battery?

No, 10 amps is generally safe for charging most car batteries. It’s a moderate rate that balances speed and battery health, especially for standard lead-acid batteries in passenger vehicles. However, always check the battery label or consult the manufacturer’s guidelines. Some smaller or AGM batteries may recommend lower currents (2–6 amps) to prevent overheating or overcharging.

2. How long to charge a deep cycle battery at 10 amps?

Charging time depends on the battery’s capacity. For example, a 100Ah deep cycle battery will take approximately 10 hours at 10 amps under ideal conditions. But real-world efficiency varies—if the charging system is 85% efficient, the same battery may take closer to 11.8 hours. Always calculate time using this formula:

Charging Time = Battery Capacity (Ah) ÷ (Charging Current × Efficiency)

3. How many amps does it take to charge a 12V battery?

The ideal charging amps depend on the battery size and type. For a small 12V battery (like 20–35Ah), 2 to 5 amps is usually sufficient. For larger batteries (50–100Ah), a 10 amp battery charger is a good choice, offering a faster yet safe charging rate. Always follow the specifications from your 12v battery manufacturer to avoid overloading the battery or damaging its cells.

Learn More About Battery

According to reports, SMC Global Power, the energy business subsidiary of the Philippine conglomerate San Miguel Corp (SMC), said a few days ago that it will start operating a 690MW battery energy storage project at the beginning of this year. The company expects to deploy 31 battery energy storage systems in 2022, with a cumulative installed capacity of 1GW.

SMC Global Power began to deploy battery energy storage systems last year, when the company revealed that several battery energy storage projects across the Philippines were about to be completed. The company also announced that it will deploy 31 battery energy storage systems by the end of 2022, not only to provide power reliability and frequency control services, but also to integrate 3GW of intermittent renewable energy.

Ramon See Ang, president of SMC, said at the time that the company will deploy solar + energy storage projects in 10 locations in the Philippines, and these projects are scheduled to start operations in 2022.

Although the progress of these solar + energy storage projects has not been updated since then, several large battery energy storage projects owned by SMC have been connected to the grid. The energy storage system integrator Fluence, a joint venture between Siemens and AES, said last year that the company has commissioned two 20MW/20MWh battery storage systems in the 470MW/470MWh energy storage combination that it signed with SMC Global Power to supply and maintain. Can project. The installed capacity of these battery energy storage projects deployed by the company ranges from 20MW to 60MW. The energy storage portfolio purchased and deployed by Fluence for SMC Global Power will be deployed at 13 sites.

Wärtsilä announced in May 2021 that two battery energy storage projects for SMC Global Power have been put into use. The scales of these two energy storage projects are 20MW/20MW and 40MW/40MW respectively, which are part of the 100MW/100MW system energy storage deployment contract announced by Wärtsilä.

According to a document recently released by SMC Global Power, the company’s deployment of battery energy storage projects aims to expand its renewable energy portfolio, including the deployment of solar power generation facilities, liquefied natural gas and hydroelectric power generation facilities to meet the needs of the Philippines for reliable and affordable power generation. The continuous demand for electricity

Are Solar Batteries Worth It?

Table of Contents

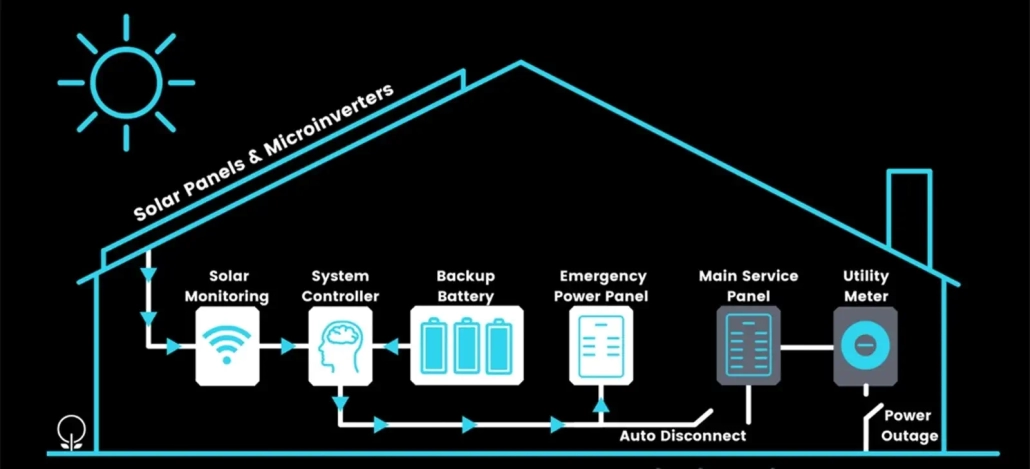

Absolutely! Choosing a solar battery for your home is often a wise decision when the money you save is more than the cost of the battery. Think of a solar battery as an investment. While it might add around $10,000 to your solar setup, it pays off through various benefits. Here are some ways solar batteries shine:

- Beat High Prices: Dodge the peak electricity rates with a time-of-use tariff, where costs fluctuate throughout the day.

- Lower Energy Bills: Cut down on how much power you pull from the grid, especially if your bill includes demand charges.

- Reliable Backup: Solar panels vary in output, but a charged battery ensures your lights stay on during power outages or cloudy days.

Why Solar Batteries Are Helpful

Using a solar battery is particularly beneficial if your local power supplier doesn’t support net metering. This means, instead of getting credits for extra solar energy you send back to the grid, you can store it in your battery for later use. It’s a smart move financially, provided the battery costs less than what you’d typically pay for grid power at night.

Also, don’t forget about the 30% federal tax credit, which isn’t just for solar panels! It’s available for home batteries too. Combining this with other local incentives means the return on your solar battery investment gets even better.

How Long Do Solar Batteries Last?

1. Frequency of Usage for Your Solar Batteries

You might notice how your phone or laptop battery doesn’t last as long after a few years. A battery that used to last 12 hours may only last three now. This drop happens to all batteries over time. The more you use and recharge your battery, the shorter its life becomes. Eventually, batteries can’t store or release enough power to be useful.

The lifespan of batteries varies a lot. It’s not about how many years they’ve been around but how often you use them. For instance, if you’re off the grid and use your battery every night, it will wear out faster than if you’re connected to the grid and only use the battery during power outages.

To extend the life of your batteries, keep an eye on the Depth of Discharge (DoD) recommended by the manufacturer. DoD is how much of the battery’s power you use. For example, if you use 10 kWh of a 13.5 kWh battery, the DoD is 74%. Staying within the advised DoD helps your battery last longer.

2. Choosing Your Type of Solar Battery Installation

When it comes to solar storage, you’ve got three main types of batteries: lead-acid, lithium-ion, and saltwater. Lithium-ion stands out as the longest-lasting and often has the best ability to hold power. They’re not the cheapest, but their longer life and high Depth of Discharge (DoD) rate, usually up to 80%, mean you get more use from your stored energy and they might save you money over time.

Lead-acid batteries have been popular for a long time, especially for those living off-grid. They cost less and can store a decent amount of power. However, they don’t last as many charge cycles and have a lower DoD rate, between 30% and 50%. So, while they’re cheaper at first, you might end up replacing them more often.

Saltwater batteries are the new players. They’re safe and environmentally friendly, using salt to hold and release energy. They tend to outlast lead-acid batteries but don’t quite reach the lifespan of lithium-ion batteries. Like lithium-ion, they also have a high DoD rate.

Also, when choosing your solar battery, look at the warranty. Many manufacturers promise their batteries will last a certain number of cycles or years. This warranty means you might not have to pay if the battery doesn’t perform as expected.

3. Storage Conditions for Your Batteries

Batteries don’t like being too hot or too cold. It’s best to keep them in a place like a garage or basement where it’s not too hot or cold. This helps them last longer than if they were outside in tough weather.

When it’s really hot, batteries work harder, and this can make them wear out faster. When it’s freezing, the power inside the battery moves slower, and it won’t last as long as it should. Keeping your battery in a place that’s not too hot or cold helps it work better and last longer.

Lead-acid batteries are pretty sensitive to temperature changes. Most of the time, they do best when kept between 40°F and 80°F. Lithium-ion batteries are a bit tougher. They can handle being a bit below 0°F and up to 140°F, but it’s still better to keep them somewhere that’s not too extreme.

Saltwater batteries also like milder temperatures, best between 23°F and 104°F. They handle temperature changes better than lead-acid batteries but aren’t as tough as lithium-ion ones.

4. The Cycle of Charging and Using Your Batteries

To figure out how long your solar battery might last, think about how many times it can be used up and charged again. This is called a cycle. Each time you use all the power in the battery and charge it back up, that’s one cycle. The more you use your solar battery, the quicker it will go through cycles.

Using your solar battery means it will wear out over time. This happens to all batteries. They can only be charged and used so many times before they don’t work as well anymore. That’s why different batteries last for different lengths of time.

5. Care and Cleaning for Battery Longevity

Solar batteries need a bit more attention than solar panels, which are pretty low-maintenance. For lithium-ion batteries, just check how much power they have every so often. No matter what kind of battery you have, it’s important to keep them clean. Wipe off any dust or dirt and make sure the parts you connect wires to are clean too. Products like the Anker 767 Solar Generator are designed to be tough, resistant to flames, and not affected by sunlight, making them easier to look after.

Solar Batteries: How Well Do They Work?

Solar power is getting more popular because it helps save money and is good for the planet. The problem used to be that solar panels only worked during the day. Any extra energy you didn’t use went back to the power grid.

Now, with solar batteries, you can keep the power your panels make and use it later, like at night when everyone is using a lot of electricity. This way of using your own solar power is called self-consumption and it’s a great way to cut down on energy bills.

When you add a solar battery to your home, you can use much more of the solar power you make. For example, adding a 4 kWh battery to a 5 kW solar system can double how much solar energy you use, from 30% to 60%.

Having a solar battery means you rely less on the power grid and save more money, especially as the payments for giving extra power to the grid get smaller. Plus, if there’s ever a power outage, you’ll still have electricity thanks to your battery.

Selecting the Right Solar Battery

How Do you Test a Solar Battery Bank?

It’s smart to keep an eye on your solar batteries, and you can do this in a couple of ways:

The easiest method is to fully charge the batteries in your solar battery bank first. Then, use a multimeter to measure and write down the voltage of each battery. After that, disconnect them from any solar panels and let them sit for a few days. Check the voltage again after this period. If a battery’s voltage has dropped without being used, it likely has a problem, often a broken cell.

Another way is to test each battery by using it to power something, like a lightbulb or heater. Write down the battery’s voltage before you connect the load, then let it run for about 30 to 90 seconds and measure the voltage again. Compare these numbers for all the batteries. A faulty battery will show a bigger drop in voltage compared to the others.

How Much Do Solar Batteries Cost

In the United States, if you’re looking at the EnergySage marketplace, expect to spend about $10,000 to $20,000 for a typical home battery, including the installation. Prices can vary a lot based on different things.

You might be curious about the starting prices for some well-known solar batteries. For those we don’t have exact prices for, we’ve given an estimated total cost that includes installation.

| Battery Brand | Cost |

| Tesla Powerwall | $8,500 |

| Generac PWRcell | $9,999 |

| sonnen eco | $10,000 |

| LG Chem RESU | $9,500 – $13,000 with installation |

| Panasonic Evervolt | $15,000 – $20,000 with installation |

In Australia, Solar Choice keeps track of the average cost of home solar batteries using information from over 200 solar installers. Usually, these batteries cost about $1,000 to $1,300 per kWh of capacity when installed, and this can change based on the brand, size, and where you live.

Here are the latest prices we’ve got, not counting any rebates you might get from your state:

| Battery Size | Battery Only Price | Battery + Inverter/Charger |

| 3kWh | $4,200 | $4,700 |

| 8kWh | $10,000 | $11,100 |

| 13kWh | $16,300 | $17,600 |

| 18kWh | $23,900 | $25,900 |

| Battery Size | Only Battery Price |

| 5kWh Battery | $1280.91 |

| 10kWh Battery | $2547.32 |

| 15kWh Battery | $3833.6 |

| 20kWh Battery | $5109.7 |

| 30kWh Battery | $7693.2 |

(Please note: We only supply batteries. The price of solar batteries may vary each quarter. Before placing an order for our products, please contact us.)

Best Solar Batteries

MANLY 5kWh Battery

The 5kWh battery, backed by a 10-year warranty and a range of certifications including UN38.3, IEC62133, UL, and CE, maintains stability even in the most extreme conditions. Constructed from LiFePO4 cells, it meets the highest safety requirements. Enhance its performance with a customizable smart BMS that not only monitors but also balances the cells, ensuring maximum protection. This BMS seamlessly integrates with leading inverters such as Growatt, Goode, Deye, Luxpower, and SRNE.

MANLY 10kWh Battery

Discover our 10 kWh home battery, tailored for solar energy storage solutions. This wall-mounted unit boasts a 48V and 200Ah specification, powered by superior MANLY lithium iron phosphate cells for unmatched safety and efficiency. Designed for endurance, it offers 8000+ deep cycles, assuring lasting reliability. The powerwall features a maximum 100A discharge capacity and is safeguarded by an integrated BMS. Its modular design is sleek yet sturdy, with laser welding to enhance durability. The 10kWh battery is not only easy to install but also comes with critical safety features like overvoltage and overcurrent protection, ensuring secure operation. Plus, its robust build is engineered to withstand severe impacts, mitigating risks of explosions or fires.

MANLY 15kWh Battery

The 30kWh battery, designed as a 48v 600ah rack-mounted unit, is ideal for residential energy storage. Crafted with A-grade LiFePO4 lithium iron phosphate cells, it provides top-notch safety and reliability. Its high conversion efficiency and powerful output are complemented by an impressive 95% energy ratio, significantly minimizing the product’s size and weight for economical shipping and easy installation.

Optional LCD displays keep you informed about the battery’s working status, voltage, and cycle count. This battery is compatible with major inverter brands and features an all-in-one wall-mounted design for hassle-free setup. The plug-and-play nature simplifies installation further. Plus, for expansive energy needs, you can connect up to 8 of these 30 kWh lithium battery packs in parallel, offering adaptable solutions for a variety of solar home and off-grid energy storage systems.

1. Definition of agricultural robot:

Table of Contents

Agricultural robot is a robot that integrates various cutting-edge science and technology such as sensing technology, monitoring technology, artificial intelligence technology, communication technology, image recognition technology, precision and system integration technology. It is also an interdisciplinary and comprehensive integration of detection and sensing technology, information processing technology, automation control technology, servo drive technology, precision machinery technology and computer technology.

2.How Are Robots Used in Agriculture

Robots are widely used in agriculture to revolutionize farming practices and address the challenges faced by the industry. These robots offer numerous benefits and advancements that enhance farming efficiency and productivity. They are equipped with cutting-edge technologies, including artificial intelligence and machine learning, to perform complex tasks efficiently.

Agricultural robots provide real-time data gathering and analysis capabilities through the use of drones, enabling informed decision-making in crucial farming processes such as planting, irrigation, and pest control. This data-driven approach leads to improved crop yields, reduced costs, and optimized resource allocation. These robots also offer enhanced efficiency compared to traditional farming methods, resulting in significant time and cost savings for farmers.

The implementation of robots in agriculture faces challenges such as high initial investment costs and the lack of rural infrastructure for large-scale adoption. However, successful deployments have been observed worldwide, with Japan and Europe leading the way in utilizing robots for tasks such as harvesting, soil analysis, weeding, pruning, and planting. These robots have demonstrated increased efficiency and cost reduction in farming operations.

The development and integration of artificial intelligence into agriculture have further expanded the capabilities of agricultural robots. AI-driven decision support systems, such as yield prediction systems, enable farmers to make informed choices based on large datasets and sophisticated computer programs. This integration allows for more precise and optimized farming practices, contributing to increased agricultural productivity and sustainability.

Responsible innovation and user-centered design are crucial considerations in the development and adoption of autonomous robots in agriculture. As the field of agricultural robotics continues to evolve, ongoing research and inclusive discussions are needed to address ethical, social, and policy issues related to the responsible use of these technologies.

In conclusion, robots have transformed agriculture by offering advanced capabilities in data gathering, analysis, and decision-making processes. With their integration of artificial intelligence and machine learning, agricultural robots enable farmers to achieve higher efficiency, productivity, and sustainability in farming practices. The ongoing development and adoption of these technologies contribute to the growth and evolution of the agricultural industry.

3. Types of Agricultural Robots:

3.1 Picking Robot

The introduction of picking robots in agricultural has the potential to revolutionize farming practices and address key challenges faced by the industry. As the world’s population continues to grow, there is an increasing demand for food production. However, labor shortages and the need for higher productivity and efficiency pose significant obstacles.

Agricultural robots, including picking robots, offer promising solutions to these challenges. These robots can automate labor-intensive tasks involved in selective harvesting, such as picking high-value crops like apples, tomatoes, and broccoli. By using sensors, cameras, and robotic arms or grippers, picking robots can detect when crops are ripe and harvest them carefully without causing damage.

The adoption of picking robots brings numerous advantages to the agricultural sector. They offer increased efficiency, accuracy, and reduced labor costs. With the ability to work continuously and tirelessly, these robots can enhance productivity and help meet the growing demand for agricultural products. Moreover, picking robots can alleviate the physical strain and repetitive nature of agricultural tasks, improving the overall working conditions for farmers.

Research and development in agricultural robotics have made significant progress, with a focus on addressing the limitations of current systems and exploring future possibilities. The use of robots in agriculture has implications beyond environmental and economic aspects, including political, social, cultural, and security considerations. Ethical challenges associated with the widespread use of agricultural robots are being examined, and key policy choices are being highlighted to maximize the benefits of robotics in agriculture.

In conclusion, the introduction of picking robots in agricultural robotics presents an exciting opportunity to transform the farming industry. These robots offer innovative solutions to labor shortages, increase productivity, and improve overall efficiency in selective harvesting tasks. As the field of agricultural robotics continues to advance, it is crucial to consider the ethical, policy, and societal implications to ensure the optimal utilization of this technology.

3.2 Grafting Robot

Grafting robots are innovative machines that automate the grafting process in agriculture, improving efficiency and enhancing seedling survival rates. These robots have gained attention worldwide, and researchers are exploring key technologies and components involved in vegetable grafting robots. Seedling feeding, clamping, and cutting devices play crucial roles in the design and operation of these robots. Machine vision technology plays a vital role in automating the grafting process, enabling accurate seedling recognition, classification, and detection.

The integration of grafting robots in agriculture presents both benefits and challenges. These robots contribute to increased productivity, improved crop quality, and reduced labor requirements . However, challenges include speed limitations, integration with seedling biotechnology, and achieving consistent quality and speed. Ongoing research focuses on enhancing intelligence, machine vision, artificial intelligence (AI), and automation to overcome these challenges and further optimize grafting robots.

The use of agricultural robots and drones, including grafting robots, is revolutionizing farming practices. These technologies leverage computational algorithms, smart devices, and advanced navigation systems to enhance efficiency and increase crop yields. Grafting robots play a crucial role in improving crop resilience and disease resistance by providing accurate and efficient grafting solutions.

The economic implications of grafting robots in field crop production are significant. Economic analysis demonstrates cost savings, increased profitability, and the viability of robotic systems in different agricultural operations. However, further research is needed to comprehensively analyze the impact, consider farm size, explore market implications, and understand the potential for crop robotics in developing countries. Grafting robots, along with other agricultural robots, hold great potential for transforming and optimizing sustainable horticultural production.

3.3 Fertilizer Robot

Fertilizer robots play a crucial role in modern agriculture by optimizing the fertilization process in row crops. Conventional fertilization methods often result in soil degradation and erosion due to the lack of consideration for specific plant needs. To address this challenge, precision agriculture applications utilize advanced technologies such as optical sensors and laser sensors. Multispectral cameras, for instance, analyze plant growth through NDVI indices, providing valuable insights for precise fertilization decisions. Laser sensors reconstruct vegetative environments, enabling analysis using clustering techniques and point cloud processing.

The Sureveg project exemplifies the application of cutting-edge technologies in robotic fertilization processes for row crop production. By incorporating sensors, robotic systems, and control boards, this project aims to optimize selective fertilization through the extraction of crop characteristics and relevant decision-making information. Tests conducted on cabbage and red cabbage rows have demonstrated the effectiveness of these sensors, both individually and in combination, in enhancing the fertilization of vegetables.

Fertilizer robots are part of the broader concept of smart agriculture, which encompasses various technologies and innovations revolutionizing farming practices. These technologies aim to increase efficiency, reduce labor requirements, and improve operational costs in the agricultural industry. Farm automation technologies, including fertilizer robots, have shown significant benefits such as cost savings per acre in vineyards. The adoption of these technologies is driven by factors such as rising fertilizer prices, concerns over inflation, increased labor wages, and stricter regulations on fertilizers and pesticides.

Nanotechnologies also hold promise in agriculture, including the reduction of water usage in farming. These technologies leverage the unique properties of nanoparticles to enhance fertilizer efficiency and reduce environmental impact. Cynthia Goh, a Professor of Chemistry at the University of Toronto, highlights the potential of nanotechnologies in agriculture.

In summary, fertilizer robots are integral to modern agriculture, optimizing the fertilization process in row crops and improving crop yield while reducing environmental impact. These robots, along with other smart agriculture technologies, aim to revolutionize farming practices by increasing efficiency, reducing labor requirements, and improving overall sustainability in the industry.

3.4 Agricultural Product Grading Robot

Agricultural product grading robots offer immense potential for revolutionizing the agricultural industry. These robots integrate advanced technologies to automate the sorting and grading processes, ensuring consistent quality and efficiency. The introduction of these robots addresses the challenges posed by the complex and variable nature of agricultural products. Genetic and environmental factors contribute to the high variability observed in agricultural products, necessitating precise and adaptable grading systems. By employing image processing and perception technologies, agricultural product grading robots can accurately analyze the characteristics and quality of produce. This automation enhances productivity, reduces labor requirements, and ensures consistent product quality.

Precision agriculture, which relies on the integration of robotics and advanced sensing technologies, has paved the way for the development and adoption of agricultural product grading robots. These robots play a vital role in the real-time interpretation of the agricultural environment, enabling efficient and accurate sorting and grading of products. By harnessing image processing techniques, these robots can analyze the visual characteristics of products, ensuring precise grading and sorting. The utilization of robotics in the agricultural sector has witnessed significant advancements over time, and agricultural product grading robots are at the forefront of this technological progress.

In summary, agricultural product grading robots offer a promising solution for enhancing the sorting and grading processes in the agricultural industry. These robots leverage advanced technologies, such as image processing and perception systems, to automate the analysis of product characteristics and ensure consistent quality. By integrating robotics and sensing technologies, agricultural product grading robots contribute to increased productivity, reduced labor requirements, and improved overall efficiency in the agricultural sector.

3.5 Weeding Robot

Weeding robots are a promising technology in modern agriculture, offering significant advantages in labor savings and reduced pesticide usage. Traditional weeding methods are labor-intensive and environmentally harmful, making the development of efficient and sustainable weed control solutions crucial. The integration of machine vision technologies in agricultural robots enables automated weeding robots that enhance efficiency, optimize resource utilization, and improve agricultural productivity. By leveraging computer vision, machine learning, and deep learning, weeding robots can accurately detect and remove weeds while preserving crops. These robots utilize perception, decision-making, and control technologies to navigate fields autonomously, providing effective weed management and reducing environmental pollution caused by herbicides.

Leading agricultural technology companies have made significant strides in developing weeding robots that offer innovative solutions. For instance, CarbonRobotics has introduced an autonomous robot capable of distinguishing weeds from crops using laser technology. This robot employs artificial intelligence, high-resolution cameras, and powerful GPUs for image recognition, enabling precise weed elimination while preserving nearby crops. It operates with GPS and LIDAR systems, ensuring accurate navigation and obstacle avoidance. Similarly, Naïo Technologies has developed multiple weeding robots, such as Oz, Ted, and Dino, each designed for specific agricultural applications, employing camera vision, sensors, and precise tool positioning.

Weeding robots present a significant opportunity for farmers to alleviate physical strain and protect crops efficiently. These robotic solutions offer a sustainable alternative to labor-intensive weeding practices, reducing reliance on agrochemicals and promoting environmental preservation. By harnessing advanced technologies and automation, weeding robots enhance agricultural practices, streamline operations, and contribute to the overall sustainability of the farming industry.

3.6 Seedling Robot

Agricultural robots are revolutionizing farming practices worldwide, including crop seeding. These robots offer a range of benefits, such as increased efficiency, reduced labor costs, and improved crop yields. The development of low-cost agricultural robots specifically designed for crop seeding has shown promising results. These robots utilize a mobile base and a seeding mechanism to sow seedlings into the ground continuously. In tests, the robot achieved a sowing rate of 138 seedlings in 5 minutes with 92% accuracy, outperforming human workers. The implementation of such robots in agriculture can significantly reduce labor costs and improve operational efficiency. By leveraging automation and eliminating the need for human intervention, crop production yields can be increased, and the industry can address labor shortages.

The global market for agricultural robots, including seeding robots, is projected to reach USD 74.5 billion by 2024, indicating the increasing adoption and potential of these technologies. The integration of Artificial Intelligence (AI) in precision agriculture has enabled farmers to optimize inputs like fertilizer, pesticides, herbicides, and water, leading to increased yields. Additionally, aerial imaging drones equipped with sensors like RGB cameras provide valuable insights into crop health and soil conditions, empowering data-driven decision-making in agriculture. The use of various types of drones, including fixed-wing, rotary-wing, and hybrid drones, offers flexibility in agricultural applications.

The development of smart agriculture robots, including those for crop seeding, addresses the challenges faced by farmers in terms of labor scarcity and changing environmental conditions. By employing sensors and automation, these robots save time, enhance energy efficiency, and optimize crop productivity. The utilization of advanced technologies, such as Arduino boards and wireless communication, allows precise control and monitoring of the robotic vehicles. The development of such innovative robotic systems contributes to the advancement of agricultural robotics and opens up possibilities for broader applications in the industry.

The progress in agricultural robotics, including crop seeding robots, is driven by the need for increased efficiency, reduced labor costs, and optimized crop yields. These robots leverage computational algorithms, environmental perception, and precision technologies to enhance production processes. Precision agriculture, enabled by small smart devices like sensors, drones, and trackers, allows for optimized detection, spraying, weeding, and harvesting of crops. The advancements in agricultural robotics, including crop seeding robots, contribute to the commercialization and ongoing development of these technologies in the agricultural sector.

3.7 Farming Robot

he adoption of farming robots in agriculture brings about significant transformations compared to traditional working methods. These robots offer several advantages and challenges that impact various dimensions of farm operations. The integration of perception, decision-making, control, and execution techniques has led to notable improvements, but limited integration with artificial intelligence remains a restriction for widespread use. However, farming robots are emerging as crucial contributors to digital agriculture, offering benefits such as flexibility, precision, increased productivity, and continuous operation without breaks . These robots can perform tasks like planting, irrigation, fertilization, monitoring, and harvesting, reducing the need for human labor. They operate at higher speeds, with fewer errors, and navigate obstacles effectively, leading to improved product quality and lower production costs.

The introduction of farming robots in agriculture also brings about transformations in farm structure, work organization, the meaning of work, and technical-economic performance. While the impact on work is complex, studies indicate that farm size is not necessarily correlated with robotization. Skill and wage segmentation may occur in the labor market, and work reorganization involves a decrease in physical workload but an increase in mental workload for monitoring alarms. Changes in the animal-human relationship can also lead to new farmer and worker identities. However, it’s important to note that the adoption of automated milking systems did not support a reduction in working time.

Smart farming and digital agriculture, enabled by agricultural robots, address challenges such as labor shortages, declining agricultural populations, and cultivation uncertainty due to climate change. These robots, including aerial and ground robots, facilitate data collection and crop management through remote sensing. They are increasingly utilized for tasks such as monitoring, spraying, and harvesting, reducing labor shortages and long-term costs. However, agricultural environments pose challenges due to crop diversity and varying robot platforms. Despite challenges such as high initial costs, maintenance requirements, and potential job displacement, robotics in agriculture offer effective solutions for improving productivity and transforming the industry.

The advancements in agricultural robotics have resulted in the emergence of various types of farming robots capable of performing tasks like picking apples, harvesting lettuce, gathering strawberries, and removing weeds. These robots are driven by the need to address labor shortages and meet the growing global population’s demands for food. While automation seems suitable for crop harvesting, the delicate nature of fruits and vegetables presents challenges for precise robot operations. Nonetheless, advancements made by agtech companies and academic institutions have shown promise in developing robots capable of picking ripe fruit and handling lettuce harvesting. These innovations have the potential to transform the industry and contribute to meeting critical agricultural needs.

4. Lithium Batteries for agricultural robots

Lithium-ion batteries play a crucial role in powering agricultural robots, offering numerous advantages over other battery technologies. These batteries provide high energy density, reliability, and faster charging capabilities, making them ideal for the demanding requirements of agricultural applications. Manly Battery offers specialized lithium-ion battery solutions tailored for small and medium-sized agricultural robots, including driverless transport vehicles and forklifts. These modular and expandable batteries, such as the “Easy Block” and “Easy Blade,” come in various versions with different power outputs, voltages, and energy capacities. For example, the “Easy Block” pack offers voltages ranging from 12.8 to 38.4 volts, while the “Easy Blade” pack provides voltage options between 24 and 48 volts.

Lithium-ion batteries have proven to be reliable and eco-friendly solutions for the energy requirements of agricultural robots. They offer longer lifespans, higher energy densities, and improved power and load capacities compared to lead-acid batteries, all in a smaller form factor. With their advanced technology, lithium-ion batteries contribute to operational efficiency in agricultural applications by reducing head length in truck and pallet loading, enabling narrower aisles, and maximizing storage space. Manly Battery, as a sustainable partner in the agricultural robotics sector, provides both standard and customizable lithium-ion battery options to meet the diverse needs of users and support the industry’s growth.

In the agricultural robotics market, battery power is crucial, considering factors such as accessibility, reliability, longevity, convenience, and cost. While lead-acid batteries were commonly used in the past, many designers are transitioning to lithium-iron phosphate (LFP), lithium nickel cobalt aluminum (NCA), or lithium nickel manganese cobalt (NMC) technologies for improved energy density and cycle life. Manly Battery’s experience in battery technology, such as the transition from lead-acid to NMC technology, demonstrates the significant benefits and market acceptance of lithium-ion batteries in terms of higher energy density, efficiency enhancements, and extended warranties. The use of cylindrical 18650 or 21700 cells allows for greater granularity in the design of the battery system.

Lithium-ion batteries also find extensive use in the automated guided vehicles and autonomous mobile robots (AGV/AMR) market, providing advantages such as longer run times, lighter loads, and faster, more efficient charging compared to lead-acid batteries. These batteries prove to be the optimal choice for mobile robots in various industries, including agriculture, as they offer superior performance, increased productivity, and enhanced workplace safety. While the exact voltages of lithium-ion batteries for agricultural robots may vary depending on specific applications and configurations, they typically range from 12.8 to 48 volts .

In summary, lithium-ion batteries provide the necessary power, reliability, and energy density required for agricultural robots. With their advanced technology and customizable options, these batteries contribute to the sustainable and efficient operation of autonomous mobile robots in agriculture.

5. Conclusion

The functions of agricultural robots are very complete and can replace part of human labor. Robots can do some things that humans cannot do, and their work efficiency is very high. They can engage in heavy manual labor, monotonous and repetitive tasks, such as spraying pesticides, harvesting and sorting crops, etc., which can liberate a lot of human resources. Robots are replacing or have replaced the heavy manual labor of humans, and can work continuously without interruption, which greatly improves labor productivity and is an indispensable and important link in the intelligentization of agriculture.