How Long To Charge a 12v Battery At 10 Amps

Table of Contents

- How Long To Charge a 12v Battery At 10 Amps

- Factors Affecting Charging Time

- Calculation of Charging Time

- The Steps To Charge a 12V Battery

- Practical Considerations

- Can You Speed Up Charging?

- Troubleshooting Common Battery Charging Issues

- Safety and Maintenance

- Conclusion

- FAQ

- Learn More About Battery

- 2023 Lithium Ion vs Lead Acid: A Detailed Comparison

- What Are Lithium Ion Batteries?

- What Is Lead Acid Battery?

- Lithium Ion vs Lead Acid Battery: 10 Key Differences

- Lithium Ion vs Lead Acid: Which Lasts Longer?

- Lithium Ion vs Lead Acid: Prolonging Your Lithium Ion Battery’s Health

- 6 Primary Types of Lithium Ion Batteries

- LiFePO4 Batteries: Leading the Charge in Lithium-Ion Technology

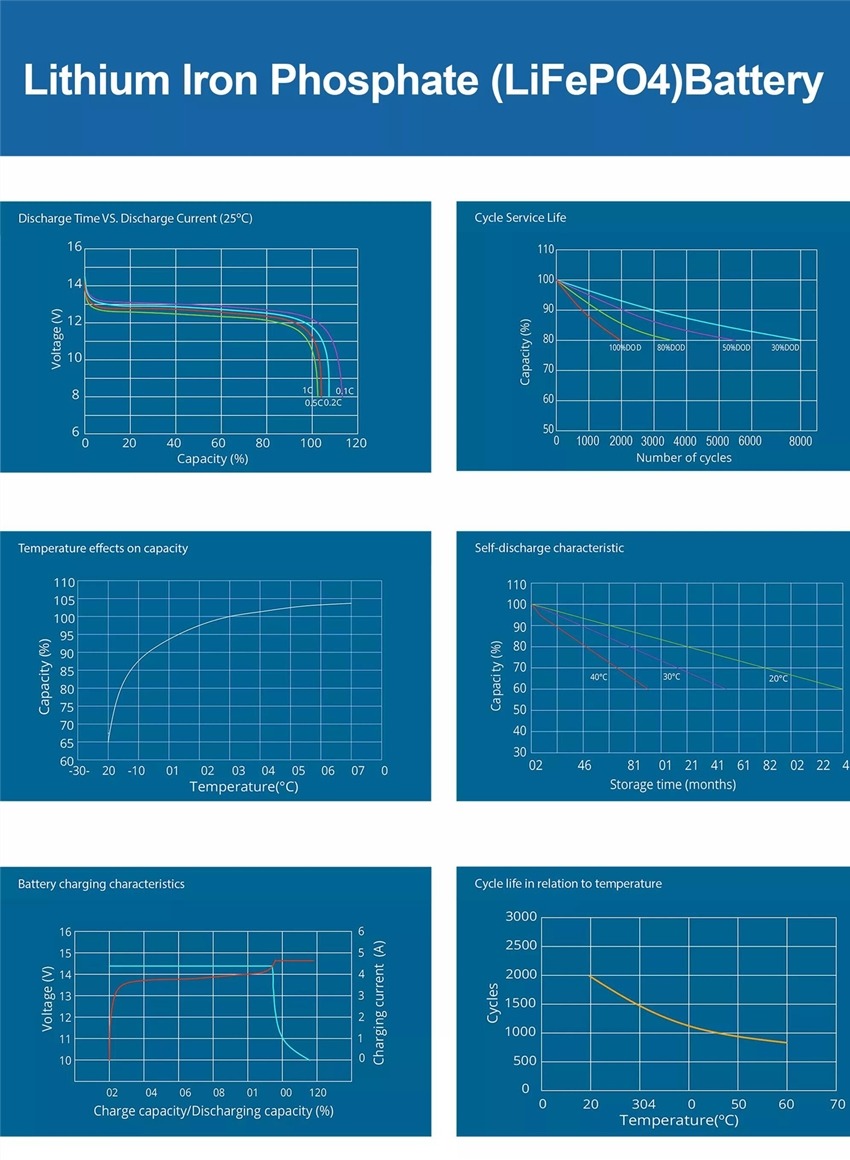

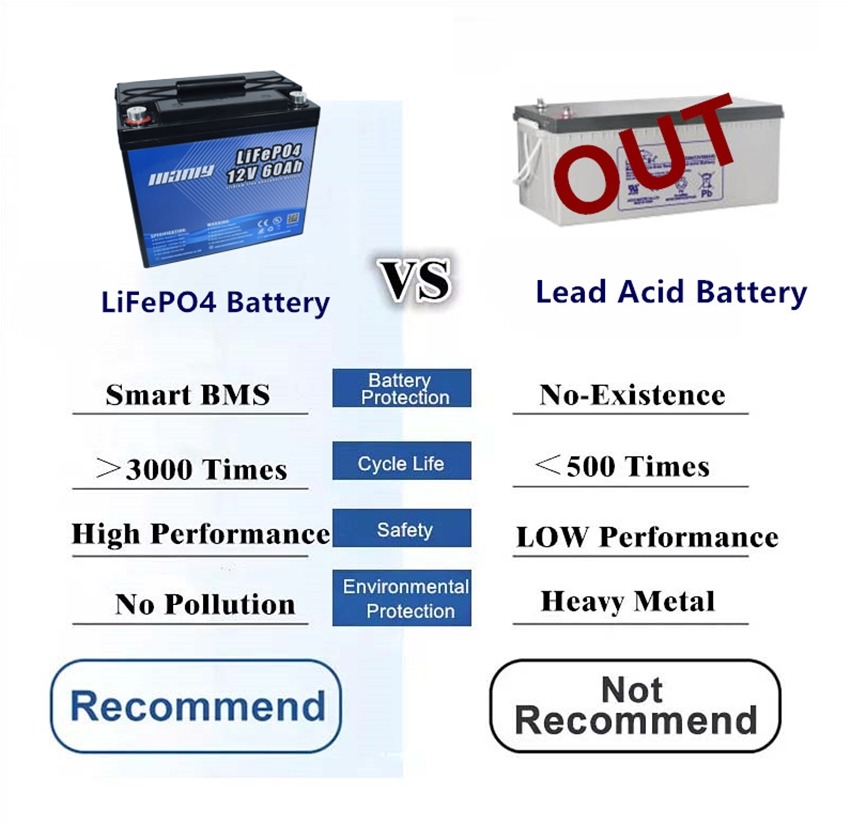

- Lithium Iron Phosphate Battery Vs Lead acid

- MANLY LiFePO4 Battery vs Other Brands LiFePO4 Battery

- Unlocking the Potential of Lithium Batteries Across Industries

- Six Important Parameters of Lithium Batteries

- 1. Battery capacity

- 2. Nominal voltage

- 3. Charge termination voltage

- 4. Discharge termination voltage

- 5. Internal resistance of the battery

- 6. Self-discharge rate

- Lithium battery PCM principle

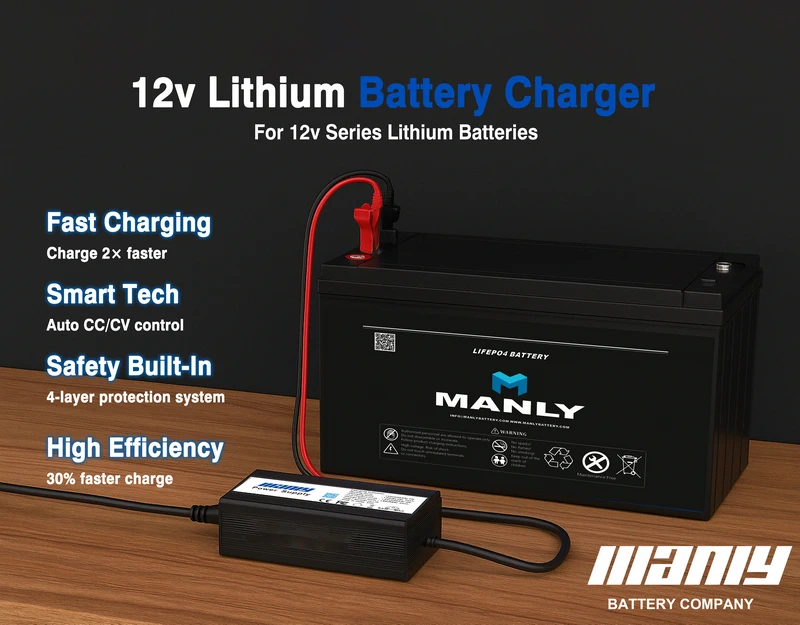

Charging a 12V battery with a 10 amp battery charger might sound simple, but many factors can affect how long it actually takes. From battery size and health to temperature and charger efficiency, each detail plays a role in determining your total charge time. Whether you’re using a smart model from a china battery charger factory or a basic unit from your local store, understanding these variables can help you charge faster, safer, and smarter. This guide breaks down the math, best practices, and common issues so you can get the most out of your battery chargers every time.

Factors Affecting Charging Time

1. Battery Capacity (Ah)

Battery capacity, measured in amp-hours (Ah), represents how much electric charge a battery can hold. Simply put, the larger the capacity, the longer it takes to charge. For example, if you’re using a 10 amp battery charger to charge a 100Ah battery, it would take roughly 10 hours to reach a full charge. The basic formula is:

Charging Time (hours) = Battery Capacity (Ah) ÷ Charging Current (A)

So, if you’re charging a 20Ah battery at 10 amps, expect it to take about 2 hours. A 50Ah battery would need approximately 5 hours under the same conditions. This relationship remains consistent across various battery sizes, assuming the charger maintains a steady current throughout the process.

2. Charging Current (Amps)

The charging current is the amount of electrical current delivered to the battery, measured in amps. Higher currents can reduce charging time, but they also raise the risk of excess heat, which can damage internal components over time. That’s why using a charger with the right current output—like a 10 amp battery charger for mid-sized batteries—is essential. This balances faster charging with the safety and longevity of the battery. Always follow the recommendations provided by the battery charger manufacturer or the battery’s technical datasheet to prevent overheating or short cycling.

3. Efficiency of the Charging Process

Not all the energy you feed into a battery gets stored—some is lost, usually as heat. Charging efficiency refers to the proportion of input energy that the battery can actually retain. For example, if a battery’s charging efficiency is 90%, then 10% of the energy is lost in the process. This means the actual time to charge may be longer than the theoretical value. Lithium-ion batteries, especially those produced by top china smart battery charger suppliers, generally boast higher efficiency levels (up to 95%) compared to traditional lead-acid types, which can drop below 85%. The type of charger also matters—china 12v lithium battery charger models are often optimized for better efficiency and heat management.

4. Importance of Battery Health

Battery health is a major factor in determining how long charging will take. As batteries age or experience repeated deep discharges, their internal resistance increases, slowing down the charging process. Environmental conditions—like extreme heat or freezing cold—can also reduce a battery’s ability to accept and hold a charge. A degraded battery might never fully charge or may take significantly longer than expected. To maintain performance, avoid exposing the battery to harsh temperatures and refrain from letting it discharge completely. Consistent maintenance not only helps preserve capacity but also ensures reliable operation with battery chargers of all types, including those from a china battery charger factory.

Calculation of Charging Time

Example Calculation

To determine how long it takes to fully charge a battery, you can start with a basic formula:

Charging Time (hours) = Battery Capacity (Ah) ÷ Charging Current (A)

Let’s break it down with a practical example. Suppose you’re charging a 100Ah battery using a 10 amp battery charger. The estimated charging time would be:

100Ah ÷ 10A = 10 hours

This calculation assumes perfect charging conditions—specifically, 100% efficiency. But in real-world applications, charging isn’t that flawless. Energy is lost in the form of heat, and actual charging efficiency usually ranges between 80% and 95%, depending on the battery chemistry and the quality of the charger.

To get a more accurate estimate, you should factor in charging efficiency. The revised formula looks like this:

Charging Time = Battery Capacity (Ah) ÷ (Charging Current (A) × Charging Efficiency)

Let’s say the efficiency is 85% (or 0.85 as a decimal). Using the same 100Ah battery and 10 amp battery charger, the calculation becomes:

Charging Time = 100Ah ÷ (10A × 0.85) ≈ 11.76 hours

So, instead of 10 hours, it would actually take nearly 11.8 hours to fully charge the battery under normal efficiency conditions. This adjustment reflects the typical loss that occurs during the conversion of AC power to stored DC energy inside the battery.

These formulas are especially helpful when selecting chargers from a battery charger manufacturer or comparing models from a china battery charger factory. Whether you’re choosing a basic china battery charger or a high-performance china smart battery charger, knowing how efficiency impacts charging time helps ensure you don’t undercharge or overwork your battery.

The Steps To Charge a 12V Battery

Charging a 12V battery correctly isn’t just about plugging in a charger—it’s a step-by-step process that helps you get the most out of your battery while keeping things safe. Whether you’re using basic battery chargers or a high-efficiency china smart battery charger, following the right steps ensures consistent performance and extends battery life.

1. Preparation

Ensure Proper Ventilation

Start by choosing a well-ventilated area. Charging a lead-acid or flooded 12V battery can release hydrogen gas, which is highly flammable. To reduce risk, make sure the area is free of open flames, sparks, or smoking.

Check Compatibility

Before connecting anything, confirm that your charger matches your battery’s voltage and chemistry. For example, a 12v battery manufacturer might require a charger tailored for lithium, AGM, or lead-acid cells. Using an incompatible charger may reduce battery performance or cause permanent damage.

Inspect All Equipment

Look over both the battery and the charger. If you see corrosion on the terminals or cracks in the casing, clean or replace the parts before proceeding. Chargers from reliable sources like a china battery charger factory are designed to reduce risk, but visual inspection is always the first line of safety.

2. Connecting the Charger

Attach the Positive Clamp

Take the red clamp from the charger and securely connect it to the battery’s positive terminal, marked with a “+” sign.

Attach the Negative Clamp

Then, connect the black clamp to the negative terminal, marked with a “–” sign. Always follow this sequence to minimize sparks and protect your gear.

3. Setting Charging Parameters

Adjust to the Right Settings

Set the charger to deliver the correct current. For medium-capacity batteries, a 10 amp battery charger offers a safe and efficient balance between charge time and heat generation.

Select the Proper Charging Mode

Modern china 12v lithium battery charger models often include selectable modes—standard, AGM, lithium, etc. Choose the one that aligns with your battery’s type to prevent overcharging or undercharging.

4. Initiating the Charging Process

Turn on the Charger

Once everything is securely connected and properly set, switch on the charger. If you’re using a smart charger from a trusted battery charger manufacturer, the device will likely auto-regulate voltage and current.

Monitor Charging Progress

Watch the status indicators or digital display if your charger includes one. Many china battery charger models provide real-time voltage or charge percentage, helping you track the process without guesswork.

5. Completing the Charge

Turn Off the Charger First

Before disconnecting anything, power down the charger completely. This step prevents electrical arcing and ensures a safe shutdown.

Disconnect Clamps in Reverse Order

Remove the black (negative) clamp first, then the red (positive) clamp. Reversing the connection sequence reduces the risk of a short circuit.

6. Post-Charging Checks

Verify the Voltage

Use a multimeter to confirm the battery is fully charged. A typical reading should be around 12.6 to 12.8 volts for most 12V lead-acid batteries at rest.

Tidy the Area

Once done, clean up the workspace. Remove tools, wipe down the charger, and store cables properly to keep your setup ready for the next use.

Practical Considerations

Impact of Temperature on Charging Time

Temperature plays a major role in how efficiently and safely a battery charges. Charging performance changes significantly depending on how hot or cold the environment is.

Cold Temperatures Slow Charging

When batteries are exposed to low temperatures—especially below 32°F (0°C)—their internal resistance increases. This makes it harder for ions to move within the cells, slowing down the charging process. For lithium-ion batteries in particular, cold conditions can cause lithium plating, which permanently reduces capacity and raises safety concerns. Studies from Battery University and others confirm that charging lithium-ion cells below freezing should be avoided whenever possible.

Heat Speeds Up Reactions—But Increases Risk

At higher temperatures, electrochemical reactions inside the battery accelerate. This may seem like an advantage for faster charging, but it comes at a cost. Excessive heat raises the chance of thermal runaway—a chain reaction where heat builds up uncontrollably, potentially causing the battery to swell, leak, or even ignite. Using china smart battery charger models with built-in temperature sensors can help manage these risks.

Best Practice: Charge at Room Temperature

For safety and efficiency, it’s best to charge batteries at moderate room temperature—around 77°F (25°C). This range supports stable electrochemical performance while minimizing stress on the battery materials.

Can You Speed Up Charging?

Yes—charging a battery faster is possible, but it comes with trade-offs. You can reduce charging time by increasing current, using fast-charging technology, and managing environmental conditions. However, rushing the process too often can shorten battery life. The key is to find the right balance between speed and longevity.

1. Use a Higher-Current Charger

The easiest way to speed up charging is to increase the current. For example, a 10 amp battery charger can fill a 100Ah battery in roughly 10 hours. By contrast, a 5 amp charger would double that time. The math is simple, but the safety isn’t—charging too fast with an incompatible charger can lead to overheating or battery damage.

Always check the battery’s rated maximum charge current, which is typically listed in the datasheet from your 12v battery manufacturer. Overloading the cells can reduce capacity over time or cause failure. Choosing a charger that matches your battery type and size—such as one from a trusted china battery charger factory—helps protect both speed and safety.

2. Utilize Fast-Charging Technologies

Fast-charging protocols like USB Power Delivery (PD) and Qualcomm Quick Charge (QC) are designed to increase power delivery without sacrificing safety. These systems dynamically adjust voltage and current based on real-time feedback between the charger and the device. For instance, Quick Charge 4.0 can push up to 27 watts, cutting down charge time significantly compared to traditional 5W outputs.

That said, the charger and the device must both support the same fast-charging standard. Using a china smart battery charger or a china 12v lithium battery charger that matches your battery’s chemistry—like LiFePO4 or NMC—is essential. Many advanced battery chargers also include protections for overvoltage, overcurrent, and thermal regulation to ensure charging stays efficient and safe.

3. Optimize Charging Environment

The temperature around your battery has a direct impact on how fast and efficiently it charges. Charging at room temperature—about 77°F (25°C)—allows batteries to perform optimally. When it’s too cold, internal resistance increases, slowing down the charging reaction. When it’s too hot, chemical activity speeds up—but so does battery degradation.

To get the most from your battery chargers, place them in a well-ventilated, shaded space away from heaters, direct sunlight, or cold drafts. Maintaining this temperature range helps chargers—especially high-performance units from a battery charger manufacturer—deliver consistent results without stressing the battery.

4. Consider Battery Health

While fast charging can be convenient, repeated exposure to high currents can cause additional heat buildup inside the cells. This can accelerate wear and reduce the total number of charge cycles a battery can handle. For long-term use, it’s wise to alternate fast charging with slower, controlled cycles.

Many smart chargers today include a battery health mode that limits current after a certain voltage threshold. If you regularly rely on fast charging, look for this feature in models from leading china battery charger suppliers to help extend battery life while still saving time when it counts.

Troubleshooting Common Battery Charging Issues

If your battery isn’t charging as expected, don’t panic. Many charging problems can be traced to common causes—and most can be fixed quickly once you know what to look for. Below, we walk through frequent charging issues and offer practical solutions to keep your battery chargers and batteries performing reliably.

1. Battery Not Charging

Potential Causes and Fixes:

Damaged Charger or Cable

Inspect the power cord and charging unit for signs of fraying, bent prongs, or overheating. Swap in another charger—ideally from a trusted battery charger manufacturer—to rule out hardware failure.Wrong Charger Type

Using the wrong charger can completely prevent charging. For example, a lithium battery requires a dedicated lithium battery charger—not just any generic model. Always verify that your charger matches your battery’s voltage and chemistry.Incorrect Terminal Connections

Check that the red (positive) and black (negative) leads are connected properly. Reversed clamps or loose terminals can disrupt the charging process or cause damage.Battery Management System (BMS) Lockout

Some batteries, especially lithium types, use a BMS that can temporarily shut off charging to protect the cells. If the system won’t reset, contact the 12v battery manufacturer or use a smart diagnostic charger designed for BMS-equipped batteries.

2. Slow Charging

Common Explanations:

Low Charging Current

If your charger supplies insufficient current, expect long charging times. Upgrading to a 10 amp battery charger, when suitable for your battery size, can significantly reduce charge duration.Battery Wear or Age

Older batteries or those that have been deeply discharged multiple times will typically charge more slowly. Run a capacity test if charging seems unusually sluggish.Temperature-Related Slowdown

Both hot and cold temperatures affect charging efficiency. Aim to charge batteries indoors at room temperature (around 77°F or 25°C) for optimal performance. Smart models from a china smart battery charger supplier can help regulate temperature automatically.

3. Charger Overheating

What to Watch For:

Prolonged High Output

Continuous operation at maximum output can cause a charger to overheat. If you’re running your charger for hours without breaks—especially near or above its rated capacity—consider taking cooling intervals or upgrading to a higher-rated unit from a china battery charger factory.Poor Airflow Around the Charger

Keep the charger in a well-ventilated, open space. Avoid covering it with objects or placing it near other heat sources.Exceeding Load Limits

Never exceed the amperage or voltage limits of your charger. Doing so may overwork the internal components and shorten the charger’s service life.

4. Battery Overheating

Primary Causes and Solutions:

Excessive Charging Current

Using a charger that exceeds your battery’s rated input current can cause internal cell temperatures to spike. Stick to the specs listed by your battery manufacturer and avoid using low-quality generic models.Hot Charging Environment

If you’re charging outdoors or in a garage during hot summer months, the ambient heat can compound internal temperature rise. Move your setup to a cooler, shaded, or climate-controlled location.Battery Degradation

Batteries naturally degrade over time. If a unit frequently overheats during charging—even under normal conditions—it may be time to replace it. Look for bulging, discoloration, or voltage drop under load as warning signs.

Safety and Maintenance

Maintaining your battery the right way isn’t just about performance—it’s also about safety. Consistent care and proper charging practices can extend battery life, reduce risks, and ensure your battery chargers operate efficiently without fail.

1. Avoiding Overcharging

Overcharging is one of the most common causes of battery damage. It leads to heat buildup, cell swelling, and a shortened lifespan.

Use Smart Chargers with Auto Shutoff

Smart charging devices—such as a MANLY 12v lithium battery charger—can automatically detect when your battery is full and stop charging to prevent overcharging. This feature protects the battery from stress and reduces the risk of overheating or fire.Set Charging Timers for Manual Chargers

If you’re using a charger without auto shutoff, calculate charging time using this formula:

Charging Time = Battery Capacity (Ah) ÷ Charging Current (A)

For example, a 100Ah battery paired with a 10 amp battery charger would require about 10 hours for a full charge. Be precise—leaving it connected too long can cause long-term damage.Avoid Overnight Charging

Don’t leave batteries on the charger for extended periods. Even with trickle charging, excess heat can build up and slowly degrade the battery over time. Unplug once charging is complete.

2. Monitoring the Charging Process

Monitoring the battery while it charges can help prevent small issues from turning into major failures.

Check for Warning Signs

Look for physical changes such as battery swelling, unusual smells, or heat from the charger. If you notice anything abnormal, stop charging immediately and reach out to the battery charger manufacturer or battery supplier.Charge in a Safe, Open Area

Avoid closed or cluttered spaces. A well-ventilated environment helps disperse heat and prevents potential fire hazards—especially critical when charging high-capacity units.Match the Charger to the Battery

Never mix incompatible gear. For instance, don’t use a lead-acid charger on a lithium-ion battery. Chargers from a reliable china battery charger factory are usually labeled for specific chemistries and voltage levels—follow those specs.

3. Manufacturer Guidelines

Following official manufacturer instructions is more than just good practice—it ensures you get the performance and safety the product was designed for.

Read the Manuals

Always follow the charging instructions provided by your 12v battery manufacturer and the maker of your battery chargers. These documents explain ideal voltage ranges, compatible accessories, and safety precautions.Routine Maintenance

Clean terminals regularly to remove corrosion, which can interfere with electrical contact. Make sure connections are tight and check for physical wear on both battery and charger components. Routine checks can prevent issues before they start.Charge at Proper Temperatures

Avoid charging in extreme heat or cold. For most battery chemistries, room temperature—around 77°F (25°C)—is ideal. Charging outside this range can slow down the process and impact long-term capacity.

Conclusion

Knowing how long to charge a 12V battery at 10 amps isn’t just about plugging in a charger and walking away—it’s about using the right tools, understanding your battery’s specs, and managing environmental conditions. With the right battery charger manufacturer and a well-matched china smart battery charger, you can optimize both charging time and battery lifespan. Whether you’re maintaining backup power systems or just keeping your vehicles ready to go, following the right charging routine ensures safety, efficiency, and long-term reliability.

FAQ

1. Is 10 amps too much to charge a car battery?

No, 10 amps is generally safe for charging most car batteries. It’s a moderate rate that balances speed and battery health, especially for standard lead-acid batteries in passenger vehicles. However, always check the battery label or consult the manufacturer’s guidelines. Some smaller or AGM batteries may recommend lower currents (2–6 amps) to prevent overheating or overcharging.

2. How long to charge a deep cycle battery at 10 amps?

Charging time depends on the battery’s capacity. For example, a 100Ah deep cycle battery will take approximately 10 hours at 10 amps under ideal conditions. But real-world efficiency varies—if the charging system is 85% efficient, the same battery may take closer to 11.8 hours. Always calculate time using this formula:

Charging Time = Battery Capacity (Ah) ÷ (Charging Current × Efficiency)

3. How many amps does it take to charge a 12V battery?

The ideal charging amps depend on the battery size and type. For a small 12V battery (like 20–35Ah), 2 to 5 amps is usually sufficient. For larger batteries (50–100Ah), a 10 amp battery charger is a good choice, offering a faster yet safe charging rate. Always follow the specifications from your 12v battery manufacturer to avoid overloading the battery or damaging its cells.

Learn More About Battery

What Are Lithium Ion Batteries?

Table of Contents

- What Are Lithium Ion Batteries?

- What Is Lead Acid Battery?

- Lithium Ion vs Lead Acid Battery: 10 Key Differences

- Lithium Ion vs Lead Acid: Which Lasts Longer?

- Lithium Ion vs Lead Acid: Prolonging Your Lithium Ion Battery’s Health

- 6 Primary Types of Lithium Ion Batteries

- LiFePO4 Batteries: Leading the Charge in Lithium-Ion Technology

- Lithium Iron Phosphate Battery Vs Lead acid

- MANLY LiFePO4 Battery vs Other Brands LiFePO4 Battery

- Unlocking the Potential of Lithium Batteries Across Industries

Lithium-ion batteries are currently the most widely used type of rechargeable batteries. They are the power source behind everyday devices like smartphones, laptops, electric vehicles, and much more.

1. The Widespread Presence of Lithium-Ion Batteries

These batteries are an integral part of our daily lives. They are found in numerous gadgets and tools, including cell phones, tablets, laptops, smartwatches, portable chargers, emergency power sources, electric shavers, electric bicycles and cars, public transport vehicles, sightseeing carts, drones, and various electric tools.

2. How Do Lithium Ion Batteries Work?

Lithium ion batteries function by utilizing lithium ions to store energy. This process involves creating a voltage difference between the battery’s positive and negative sides. The battery contains a special part called a separator, which keeps the two sides apart. This separator allows lithium ions to move across it but prevents the flow of electrons.

- Charging and Discharging Process: When you charge a lithium-ion battery, the lithium ions travel from the positive side to the negative side through the separator. Conversely, when the battery is in use (discharging), the ions move back to the positive side. This back and forth movement of ions is what generates the battery’s voltage.

- Powering Your Devices: The voltage created by the lithium-ion battery is used to power electronic devices. When a device is connected to the battery, it directs the electrons, which were blocked by the separator, to flow through the device, providing it with the necessary power.

What Is Lead Acid Battery?

Lead acid batteries are a type of rechargeable battery that harnesses the chemical interaction between lead and sulfuric acid to generate electricity. They’re commonly used in various applications due to their reliability and rechargeability. The core of these batteries is the lead submerged in sulfuric acid, which facilitates a controlled chemical reaction essential for power generation and storage.

1. How Lead Acid Batteries Function

In a lead acid battery, the electrodes are primarily composed of lead and its oxides, while the electrolyte is a sulfuric acid solution. When discharging, the positive electrode is mainly lead dioxide, and the negative electrode is lead. During charging, both electrodes become primarily lead sulfate. A single cell typically has a nominal voltage of 2.0V, can discharge to 1.5V, and charge up to 2.4V. For practical use, six single cells are often connected in series to create a standard 12V battery, with other configurations like 24V, 36V, and 48V also available.

2. Applications of Lead Acid Batteries

Lead acid batteries are versatile and find use in various sectors:

Standby Power Sources

- Telecommunications

- Solar Energy Systems

- Electronic Switch Systems

- Communication Equipment: Base Stations, PBX, CATV, WLL, ONU, STB, Cordless Phones

- Backup Power: UPS, ECR, Computer Backup Systems, Sequence, ETC

- Emergency Equipment: Emergency Lights, Fire and Burglar Alarms, Fire Doors

Primary Power Sources

- Communication Devices: Transceivers

- Power Control Vehicles: Collection Vehicles, Automated Transport Vehicles, Electric Wheelchairs, Cleaning Robots, Electric Cars

- Mechanical Tool Starters: Lawnmowers, Hedge Trimmers, Cordless Drills, Electric Screwdrivers, Electric Snow Sleds

- Industrial Equipment/Instruments

- Photography: Flashlights, VTR/VCR, Movie Lights

- Other Portable Devices

Lithium Ion vs Lead Acid Battery: 10 Key Differences

1. Differences in Material Composition

Both lithium ion and lead acid batteries operate on similar principles, but the materials they use differ significantly. Lead acid batteries employ lead as the anode and lead oxide as the cathode, with sulfuric acid serving as the electrolyte. In contrast, lithium ion batteries use carbon for the anode and lithium oxide for the cathode, with lithium salt as the electrolyte. The flow of ions between the anode and cathode through the electrolyte is what generates power in both types, reversing during charging.

2. Cost Considerations

Initially, lead acid batteries are more affordable and easier to install than lithium ion ones. However, the price of a lithium ion battery can be twice that of a lead acid battery for the same energy capacity. Despite this, lithium ion batteries offer a longer lifespan, making them more cost-effective for long term applications compared to lead acid batteries.

3. Comparing Battery Capacities

Battery capacity reflects the amount of energy a battery can store per unit volume. Lithium ion batteries boast a higher capacity than lead acid batteries, indicating a greater amount of active material within.

4. Energy Density and Specific Energy

Energy density is crucial in selecting the right battery for specific needs, showing the relationship between a battery’s capacity and its weight. Lithium-ion batteries exhibit higher specific energy compared to lead-acid batteries, making them the preferred choice in electric vehicle (EV) applications.

5. Weight and Size

Thanks to their higher energy density and capacity, lithium-ion batteries are lighter and more compact than lead-acid batteries of the same capacity.

6. Depth of Discharge (DoD) Comparison

DoD measures how much of a fully charged battery can be used without needing a recharge. Lead-acid batteries typically have a DoD of 50%, meaning only half the battery’s capacity should be used before recharging. On the other hand, lithium-ion batteries offer a higher DoD of 80%, allowing for extended use. Modern lithium-ion batteries even reach 100% DoD, showcasing their efficiency and endurance.

7. Durability and Longevity

Lead-acid batteries typically have a lifespan of up to two years with proper maintenance, including recharging after 50% usage. Over-draining can limit their life to just one year. In contrast, lithium-ion batteries boast a remarkable durability of up to 10 years, enduring up to 10,000 cycles.

8. Cycle Life

The cycle life of a battery indicates the number of complete charge and discharge cycles it can handle. Lithium-ion batteries often sustain around 5,000 cycles without significant performance loss, even when fully discharged. Lead-acid batteries, however, generally last between 300 to 500 cycles, with full discharge adversely impacting their cycle life.

9. Charging Speed

Charging speed is a key differentiator between these two types. Lithium-ion batteries can charge much faster than lead-acid batteries, making them preferable for applications needing quick recharge, like electric vehicles (EVs).

10. Safety Considerations

Both battery types pose safety risks if mishandled, especially when overcharged. Lead-acid batteries contain corrosive sulfuric acid and can produce explosive gases. Lithium-ion batteries are at risk of thermal runaway, which can also lead to explosions. Manufacturers like CATL and Panasonic Corporation are key players in creating safer battery systems. The battery’s application often dictates the choice between lithium-ion and lead-acid batteries.

Lithium Ion vs Lead Acid: Which Lasts Longer?

1. Understanding Battery Lifespan and Efficiency

When it comes to longevity, lithium ion (Li-ion) batteries generally have a longer life than lead acid batteries. This is mainly due to their higher life cycle numbers, meaning they don’t need replacing as often. This not only cuts down on replacement costs but also aligns with eco-friendly recycling practices. Additionally, Li-ion batteries are tougher, performing more effectively in demanding environments.

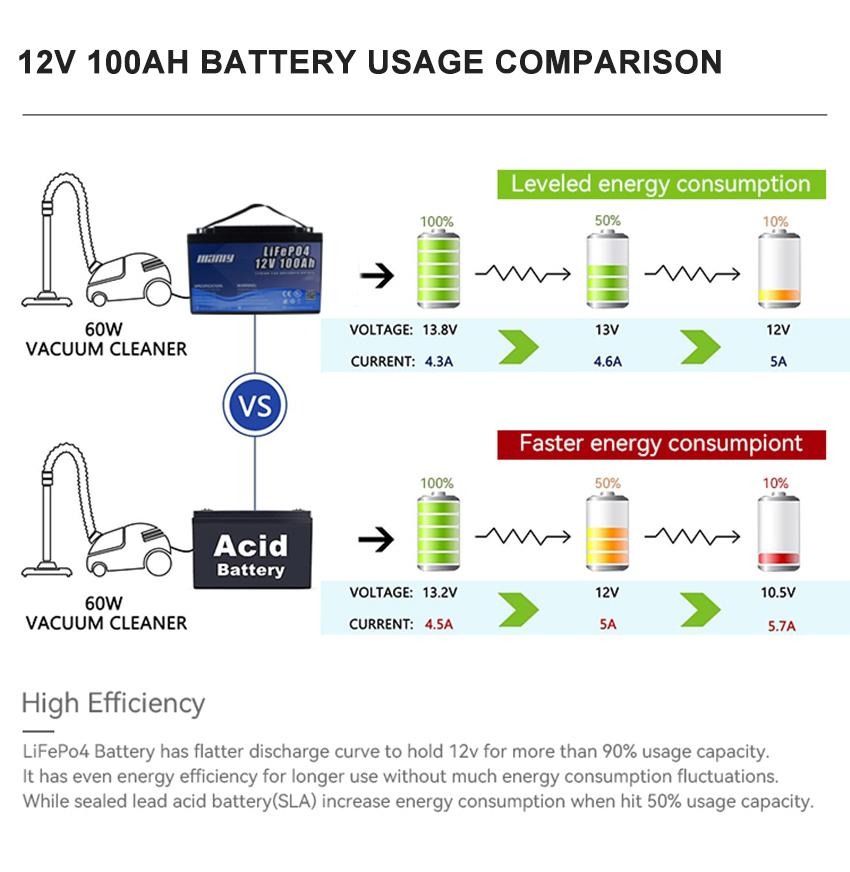

- Efficiency Matters: In the lithium ion vs lead acid comparison, efficiency plays a crucial role. Efficiency refers to the percentage of the energy stored in the battery that can be effectively utilized. Li-ion batteries are typically at least 95% efficient, significantly outperforming lead acid batteries, which have efficiencies around 80-85%.

- Battery Discharge Curve: The discharge curve is crucial as it influences how quickly a battery can charge and its effective capacity – the actual amount of energy a battery can store. Li-ion batteries have a superior discharge curve, maintaining their voltage until almost fully depleted, unlike lead acid batteries, which experience a significant voltage drop during discharge.

2. Usage Patterns: A Key Differentiator

- Lithium ion Batteries: Li-ion batteries are known for their speedy charging times, making them ideal for extended use across multiple work shifts. They lack a memory effect, allowing for partial charging without reducing their overall lifespan. A typical usage pattern includes 8 hours of operation, a swift 1-hour recharge, followed by another 8 hours of use. This cycle enables continuous usage over a 24-hour period, with only brief pauses for charging.

- Lead Acid Batteries: In contrast, lead acid batteries generate substantial heat while charging, necessitating a cooldown period. Their typical usage cycle includes 8 hours of operation, followed by 8 hours of charging and an equal period of rest. This pattern limits their use to one shift per day, requiring additional batteries for multi-shift operations. They also need well-ventilated areas for charging to prevent the buildup of hazardous gases.

Lithium Ion vs Lead Acid: Prolonging Your Lithium Ion Battery’s Health

1. Introduction to Lithium Ion Battery Care

Maximizing the lifespan of lithium ion batteries is crucial for ensuring long-term efficiency and performance. Implementing strategies such as partial discharge cycles, avoiding full discharges, and managing charging temperatures can significantly impact their durability. It’s important to note that while lead acid batteries should not be discharged beyond 50%, lithium ion batteries can handle deeper discharge cycles without adverse effects.

2. Key Techniques for Prolonging Battery Life

- Optimal Discharge Cycles: Utilize only 20-30% of the battery’s capacity before recharging. Avoid keeping the battery fully charged or fully discharged for extended periods, as both extremes can shorten its lifespan.

- Temperature Management During Charging: Charging lithium ion batteries in extreme temperatures, particularly below freezing, can reduce their longevity. Ensure the charging environment is temperature controlled to extend battery life.

- Proper Charging Practices: Use the correct charger type for your lithium ion battery to ensure it charges efficiently and safely. Lithium ion batteries require more specific charging regimes compared to lead acid batteries.

- Benefits of Lithium Ion Over Lead Acid: Lithium ion batteries offer a range of advantages over lead acid batteries, including improved performance in challenging environments and overall cost-effectiveness over their lifespan.

3. Detailed Tips for Optimal Battery Usage

- Lowering Discharge Rates: Reducing the C rate during discharge helps maintain the battery’s capacity and cycle life. Avoid high discharge rates to prevent increased internal resistance and premature aging.

- Temperature Considerations: The operating temperature significantly impacts a battery’s power consumption and efficiency. Manage temperatures effectively to enhance lithium ion battery performance.

- Partial Depth of Discharge (DoD): Favor partial discharges over full cycles. A shallower DoD results in a significantly higher number of battery cycles, thereby extending the battery’s lifespan.

- Balancing Multiple Cells: If your battery pack has more than one cell, periodic balancing is necessary to ensure even usage and prevent voltage loss. Employ methods like bypassing certain cells during charging to focus on weaker cells.

- Monitoring the State of Health (SoH): Keeping track of the SoH provides insights into the battery’s condition and remaining lifespan. A drop in SoH indicates the need for maintenance or replacement.

6 Primary Types of Lithium Ion Batteries

Lithium ion batteries, a cornerstone of modern technology, come in several types, each with unique characteristics and applications. The diversity in lithium ion batteries stems from the various active materials used in their construction, influencing their performance, longevity, and suitability for different uses.

Key Types of Lithium Ion Batteries

- Lithium Iron Phosphate (LFP): Known for their durability and safety, LFP batteries use phosphate in the cathode and a carbon electrode in the anode. These batteries are known for their long life cycle and good thermal stability. They are ideal for replacing lead-acid deep-cycle batteries due to their nominal voltage and stability.

- Lithium Cobalt Oxide (LCO): These batteries are notable for their high specific energy but are limited in high-load situations. They were commonly used in portable electronics like phones and laptops but have seen a decline in popularity due to cost and safety concerns.

- Lithium Manganese Oxide (LMO): LMO batteries, used in tools and some hybrid vehicles, offer quick charging and high specific power. They stand out for their improved thermal stability and versatility in different applications.

- Lithium Nickel Manganese Cobalt Oxide (NMC): Combining nickel, manganese, and cobalt, NMC batteries balance stability with high energy density. They are frequently used in power tools and electric vehicles.

- Lithium Nickel Cobalt Aluminium Oxide (NCA): Offering high specific energy and a respectable lifespan, NCA batteries are a popular choice in the electric vehicle industry, particularly for high-performance models like Tesla.

- Lithium Titanate (LTO): Unique for using lithium titanate instead of graphite in the anode, LTO batteries are exceptionally safe and fast-charging. They are used in various applications, including electric vehicles and energy storage, despite their lower energy density and higher cost.

LiFePO4 Batteries: Leading the Charge in Lithium-Ion Technology

Lithium Iron Phosphate (LiFePO4) batteries are one of many types of lithium-ion batteries, each defined by different cathode materials. Other common types include Lithium Cobalt Oxide (LCO), Lithium Manganese Oxide (LMO), Lithium Nickel Cobalt Aluminum Oxide (NCA), Lithium Nickel Manganese Cobalt Oxide (NMC), and Lithium Titanate (LTO). Each has unique strengths and weaknesses, making them suitable for specific applications. (Learn more about Best LiFePO4 Battery)

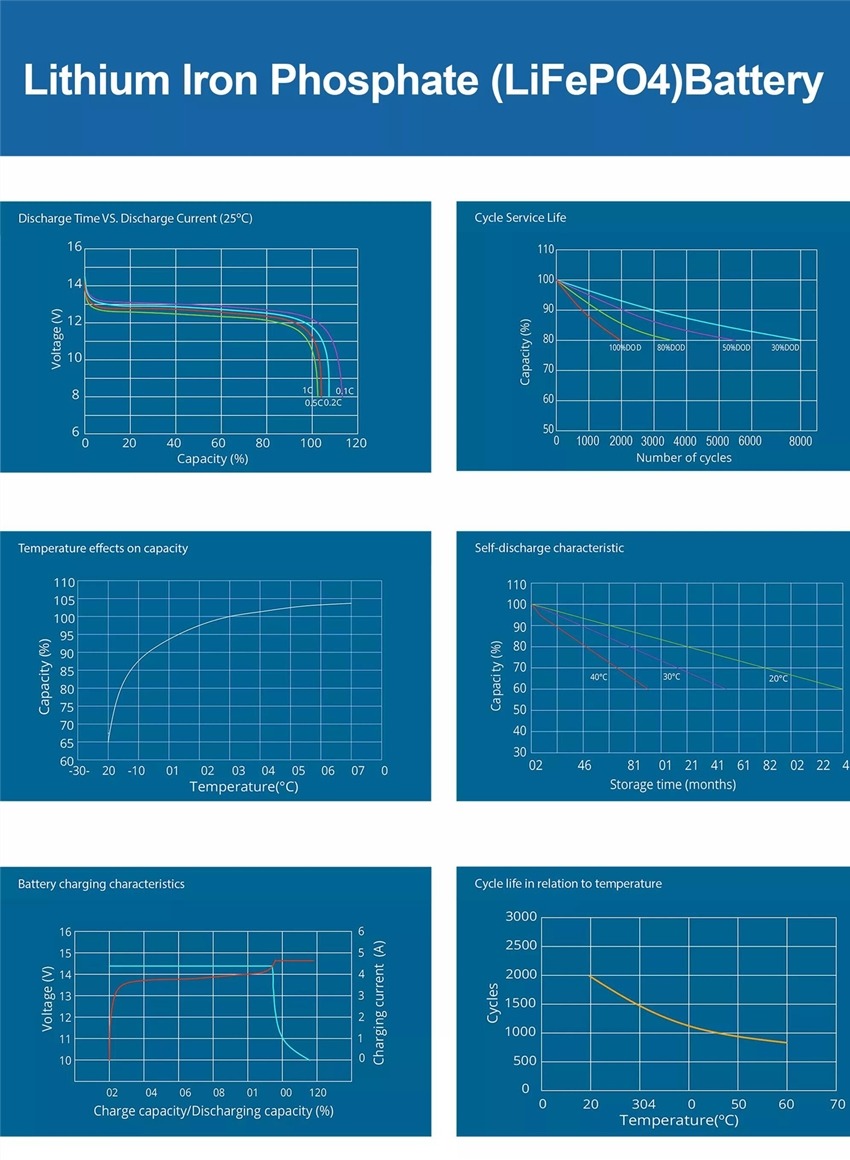

Energy Density Comparison

LiFePO4 batteries boast one of the highest specific power ratings among lithium-ion batteries, meaning they can deliver large amounts of current efficiently. However, they have a lower specific energy, indicating less energy storage capacity per unit weight compared to other types. While this may not be a concern for many applications, it can be limiting in scenarios requiring high energy density, such as in battery electric vehicles.

Battery Life Cycles

LiFePO4 batteries excel in longevity, with lifespans starting at 2,000 full discharge cycles and potentially exceeding 5,000 cycles. This extended lifespan, only second to Lithium Titanate, offers significant advantages in terms of cost-effectiveness and environmental impact.

Discharge Rates

LiFePO4 batteries commonly feature a 1C continuous discharge rate, with the potential to exceed this under certain conditions. This capability makes them suitable for high-power applications that require current spikes at startup.

Operating Temperatures

With a high thermal runaway threshold of approximately 270 degrees Celsius, LiFePO4 batteries can operate safely under higher temperatures compared to other lithium-ion types. This characteristic, combined with robust Battery Management Systems (BMS), significantly reduces the risk of thermal runaway events.

Safety Advantages

Among all lithium-ion batteries, LiFePO4 batteries are known for their stability and safety, making them a preferred choice for both consumer and industrial applications. Their safe chemistry, alongside Lithium Titanate, is ideal for applications requiring a high degree of safety and reliability.

LiFePO4 vs. Other Lithium Ion Batteries

While LiFePO4 batteries may not be optimal for small, wearable devices due to lower energy density, they excel in larger applications like solar energy systems, RVs, golf carts, and electric motorcycles. They surpass other lithium-ion batteries in cycle life, safety, and depth of discharge capabilities.

Cycle Life and Safety

LiFePO4 batteries can achieve over 3,000-5,000 cycles, with the ability to reach 100% depth of discharge without over-discharging risks. This longevity, combined with their inherent safety, makes them the safest lithium battery type available, surpassing lithium-ion and other battery types in safety metrics.

Environmental and Efficiency Advantages

Eco-friendly and rechargeable, LiFePO4 batteries outperform lead-acid batteries in terms of efficiency, life span, and environmental impact. They charge faster, have a lower self-discharge rate, and maintain consistent power even below 50% battery life, all with no maintenance requirements.

Size and Weight Benefits

LiFePO4 batteries are significantly lighter than other lithium and lead-acid batteries, enhancing fuel efficiency and maneuverability in vehicles. Their compact size also frees up space for additional applications.

Lithium Iron Phosphate Battery Vs Lead acid

Lithium iron phosphate battery:

- Durability: Lithium iron phosphate battery has strong durability, slow consumption, more than 2000 charging and discharging times, and no memory, and the general life span is 5-8 years.

- Discharge rate: Lithium iron phosphate battery can be discharged with high current, suitable for solar street lights, electric cars, electric bicycles, etc.

- In terms of volume and quality: Lithium batteries are relatively small in size.

- Battery capacity: The capacity of lithium batteries in the same volume is larger. The lead-acid battery has a capacity of about 20 amps; the lithium battery has a capacity of 8-10 amps.

- No memory effect: Lithium iron phosphate battery can be charged and used at any time, no matter what state it is in. It does not need to be discharged before recharging.

- Nominal voltage of monomer: The nominal voltage of lithium iron phosphate battery is 3.2V.

- Environmental protection: Lithium materials do not contain any toxic and harmful substances, and are regarded as green and environmentally friendly batteries in the world. The batteries are pollution-free in production and use, and have become a hot research topic.

- Safety: Lithium iron phosphate has passed strict safety tests and will not explode even in the worst traffic accidents, showing higher safety performance.

Lead-acid batteries:

- Lead-acid batteries are generally deep-charged and discharged within 300 times, have memory, and have a lifespan of about two years. And there is liquid in the lead-acid battery, after a period of consumption, if the battery is found to be hot or the charging time becomes shorter, you need to replenish the liquid. To

- Generally, the weight of lead-acid batteries is 16-30 kg, and the volume is relatively large;

- There is a large amount of lead in lead-acid batteries. If they are not handled properly after being discarded, they will pollute the environment and cause pollution during the production process. To

- The nominal voltage of a lead-acid battery is 2V, and the voltage of an ordinary lead-acid battery is usually 12V.

Comparison Table: LiFePO4 vs. Lead Acid Battery

| Feature | LiFePO4 Battery | Lead Acid Battery |

|---|---|---|

| Energy Density | High energy density, more power per unit weight. | Lower energy density. |

| Weight | Lighter, making them more suitable for portable applications. | Heavier, less suitable for applications where weight is a concern. |

| Cycle Life | Typically 2000 – 5000 cycles or more. | Around 300 – 500 cycles. |

| Efficiency | High efficiency, around 85-95%. | Lower efficiency, about 80-85%. |

| Charge Time | Fast charging capability. | Slower charging compared to LiFePO4. |

| Operating Temperature Range | Wider operating temperature range. | More limited temperature range, performance declines in extreme temperatures. |

| Maintenance | Low maintenance, no need for regular watering. | Requires regular maintenance like watering and equalization. |

| Safety | Generally safer, more stable chemistry, lower risk of thermal runaway. | Risk of acid spills and gas emissions, requires careful handling. |

| Environmental Impact | Environmentally friendlier, contains no heavy metals. | Contains lead, a toxic heavy metal, requires careful disposal. |

| Lifespan | Longer lifespan, can last up to 5 years or more. | Shorter lifespan, typically 3-5 years. |

| Cost Over Life Cycle | Initially more expensive but cost-effective over its life cycle. | Cheaper initially but less cost-effective in the long run due to shorter lifespan and maintenance. |

MANLY LiFePO4 Battery vs Other Brands LiFePO4 Battery

MANLY LiFePO4 Batteries stand out in the competitive battery market with their robust combination of innovation, quality, and versatility. Backed by over 13 years of expertise, these batteries, hailing from China’s technological hubs, offer unparalleled customization, catering to diverse applications from solar energy storage to advanced robotics. Unlike standard LiFePO4 batteries, MANLY Batteries boast a remarkable 98% energy efficiency rate, enhanced safety features, and global certifications like UN38.3, IEC62133, UL, and CE. Their commitment to durability and user experience is further exemplified by features like Bluetooth connectivity and intuitive displays. This focus on consumer-centric innovation and superior performance makes MANLY Batteries a leading choice for those seeking reliable, high-quality battery solutions, distinctly setting them apart from other brands in the market.

| Feature | MANLY LiFePO4 Battery | Other Brands LiFePO4 Battery |

|---|---|---|

| Key Competitive Advantage |

|

|

| Customization Options | Offers customization in voltage, capacity, current, dimensions, aesthetics, etc. | Customization varies by manufacturer; not all offer extensive options. |

| Certifications | Boasts UN38.3, IEC62133, UL, CE, among others. | Certification depends on the manufacturer; common ones include CE, UL. |

| Warranty | 10-year warranty. | Warranty periods vary, typically around 1-5 years. |

| Protection Features | Includes short circuit, overcharge/discharge, balancing circuits, overvoltage/overcurrent, and safety against explosion or ignition. | Standard protections include overcharge/discharge, short circuit, and temperature control. |

| Operating Conditions | Operates in -20°C to 75°C. (Advised not to charge below 0°C) | Operating temperature ranges vary, typically -10°C to 60°C. |

| Efficiency Rate | Energy efficiency rate of 98%. | Efficiency rates vary, typically around 85-95%. |

| Enhanced Features | Optional BMS, Bluetooth connectivity and battery level display. | Additional features vary by model and manufacturer. |

| Waterproof | Up to IP67 waterproof rating (depends on the customer’s waterproof requirements for the product) | Not all productions have waterproof |

| Lifespan | Lifespan of 8000+ cycles , typically 10-20 years (Longevity relies on MANLY’s expert R&D team) | Lifespan varies, typically 5-10 years depending on usage and maintenance. |

Unlocking the Potential of Lithium Batteries Across Industries

Let’s delve into the various industries where lithium batteries shine as the preferred power source:

Cold Weather Battery Guide: Top Picks for 2023

Choosing The Right Battery for Electric Scooter

Best Lithium Marine Battery: Guide to Selecting in 2023

The 6 Best Lithium Golf Cart Batteries

1. Battery capacity

Table of Contents

Generally the capacity of the battery is determined by the amount of active material in the battery, usually expressed in milliampere-hour mAh or Ah. For example, 1000 mAh can be discharged for 1 h with a current of 1 A.

1.1 Understanding Battery Capacity: Rated vs. Actual vs. Theoretical

Battery capacity can be categorized into actual capacity, theoretical capacity, and rated capacity, based on different conditions.

The capacity that a battery provides when discharged at a particular discharge rate at 25°C down to its terminal voltage is defined as the battery’s capacity during design and production. This is termed the rated capacity for a given discharge rate RH.

Battery capacity is typically measured in AH (Ampere-hours). Another method of measurement is in terms of CELL (per unit plate) in watts (W/CELL).

- For Ah (Ampere-hours) calculations, you take the discharge current (constant current) I and multiply it by the discharge time (in hours) T. For instance, a 7AH battery discharged continuously at 0.35A can last for approximately 20 hours.

- The standard charging time is 15 hours, and the charging current is 1/10 of the battery’s capacity. Fast charging may reduce the battery’s lifespan.

Battery capacity refers to the size of the stored electrical charge in a battery. The unit for battery capacity is “mAh”, known in Chinese as milliampere-hours. For larger capacity batteries, such as lead-acid batteries, “Ah” (Ampere-hours) is generally used for convenience, where 1Ah = 1000mAh. If a battery has a rated capacity of 1300mAh, and you discharge the battery with a current of 130mA, the battery can operate for about 10 hours (1300mAh/130mA = 10h). If the discharge current is 1300mA, then the operational time drops to around 1 hour. These calculations assume ideal conditions, and actual device operation may vary based on components, like an LCD screen or flash in a digital camera, which can cause large variations in current. Hence, the actual operational time for a device powered by the battery can only be approximated, usually based on real-world experience.

1.2 Unit of Capacity

Typically, battery capacity is measured in ampere-hours (Ah), and this is determined for a specific battery in mind. For instance, the question might be: What’s the capacity of this smartphone battery? Or, what’s the capacity of this electric scooter battery? These queries are unique to each battery. When the battery voltage is already defined and one isn’t considering the real-time voltage, merely stating the ampere-hours can represent the battery’s capacity.

However, when dealing with batteries of different voltages, one can’t simply rely on ampere-hours to denote capacity. Take, for instance, a MANLY 12V 20AH battery and a MANLY 15V 20AH battery. Even though both have 20AH, when powering a device with the same load, the device will work just fine, but the duration of operation will differ. Hence, the standard capacity should be measured in terms of power.

To illustrate further, consider a device that can support both 12V and 24V. If powered by a MANLY 12V 20AH battery, it can last for one hour. However, if two such batteries are connected in series, resulting in 24V 20AH, the ampere-hours remain unchanged, but the operational time doubles. In this context, the capacity should be viewed in terms of the power the battery can hold, not just the ampere-hours.

Power (W) = Power (P) * Time (T) = Current (I) * Voltage (U) * Time (T).

This approach to discussing battery capacity is more meaningful. One must be realistic and factual; otherwise, you might end up with the illogical claim that a smartphone battery has a larger capacity than an electric scooter battery, which is clearly unscientific.

2. Nominal voltage

The potential difference between the positive and negative electrodes of the battery is called the nominal voltage of the battery. The nominal voltage is determined by the electrode potential of the plate material and the concentration of the internal electrolyte. The discharge diagram of lithium battery is parabolic, with 4.3V dropping to 3.7V and 3.7V dropping to 3.0V, both of which change rapidly. Only the discharge time of about 3.7V is the longest, accounting for almost 3/4 of the time, so the nominal voltage of the lithium battery refers to the voltage that maintains the longest discharge time.

- Ternary Lithium Battery

The nominal voltage of a ternary lithium cell is 3.6V, with an operating voltage range between 2.5V and 4.2V. For a battery pack, you multiply the voltage by the number of cells in series. For instance, for a 10-series ternary lithium battery pack, the nominal voltage stands at 36V, and the working voltage range spans from 25V to 42V.

- Lithium Iron Phosphate Battery

The nominal voltage of a lithium iron phosphate cell is 3.2V, with an operational voltage range of 2.0V to 3.65V. Similarly, for the corresponding battery pack, you multiply by the number of cells in series. For example, a 15-series lithium iron phosphate battery pack has a nominal voltage of 48V, with a working voltage range of 30V to 54.75V.

So, what are the implications of a low voltage for lithium batteries?

It’s recommended that lithium batteries be stored long-term with about 70% of their charge. If not in use for 3 to 6 months, it’s advisable to cycle through one full charge and discharge. This benefits the overall lifespan of the battery pack.

If stored for extended periods without use and at very low voltages, the materials in the lithium battery can be adversely affected. Their chemical reactivity might deteriorate, which in turn impacts the battery pack’s lifespan.

Lithium-ion batteries operate at voltages ranging from 2.5V to 4.2V. When the voltage drops below 2.5V, the battery discharge terminates, and due to the closing of the discharge circuit, the current loss of the internal protection circuit drops to its lowest. However, in real-world applications, due to variations in internal materials, the discharge termination voltage can range from 2.5V to 3.0V. When the voltage exceeds 4.2V, the charging circuit is terminated to ensure the battery’s safety.

3. Charge termination voltage

When the rechargeable battery is fully charged, the active material on the electrode plate has reached a saturated state, and the battery voltage will not rise when the battery continues to be charged. The voltage at this time is called the end-of-charge voltage. The ternary lithium battery is 4.2V, and the lithium iron phosphate battery is 3.65V.

4. Discharge termination voltage

The end-of-discharge voltage refers to the lowest voltage allowed when the battery is discharged. The discharge termination voltage is related to the discharge rate.

5. Internal resistance of the battery

The internal resistance of the battery is determined by the resistance of the electrode plate and the resistance of the ion flow. During the charging and discharging process, the resistance of the image engine and the electrode plate is unchanged, but the resistance of the ion flow will increase or decrease with the concentration of the electrolyte and the charged ions. And change. When the OCV voltage of a lithium battery decreases, the impedance will increase. Therefore, when charging at low power (less than 3V), pre-charge (trickle charging) must be carried out first to prevent too much current from causing excessive heat generation of the battery.

Composition of Lithium Battery Internal Resistance

Ohmic resistance mainly arises from the electrode materials, electrolyte, separator resistance, as well as the contact resistance of current collectors and tab connections. It’s related to the battery’s size, structure, and connection methods.

Polarization resistance, which emerges instantly when current is applied, represents the cumulative tendency of various barriers inside the battery preventing charged ions from reaching their destinations. This resistance can be further categorized into electrochemical polarization and concentration polarization.

Currently, the standout 18650 lithium battery has an internal resistance of around 12 milliohms, while typical ones hover between 13 to 15 milliohms. Given that impedance can affect the battery’s performance, generally speaking, 50 milliohms is deemed normal. Between 50 to 100 milliohms, the battery remains functional, but performance starts to degrade. When exceeding 100 milliohms, parallel use is necessary, and anything above 200 milliohms is virtually unusable.

Impacts of Lithium Battery Internal Resistance

All factors that impede the movement of lithium ions and electrons from one pole to another within the lithium battery contribute to its internal resistance. Ideally, the lower the internal resistance, the better. A higher internal resistance leads to increased thermal losses, preventing high current discharge. Moreover, a high internal resistance means the battery heats up during use. Elevated temperatures can cause the battery’s discharge operating voltage to drop and its discharge duration to shorten, severely affecting battery performance and lifespan. In extreme cases, this can even pose a risk of spontaneous combustion.

6. Self-discharge rate

It refers to the percentage of the total capacity that is automatically lost when the battery is not in use for a period of time. Generally, the self-discharge rate of lithium-ion batteries at room temperature is 5%-8%.

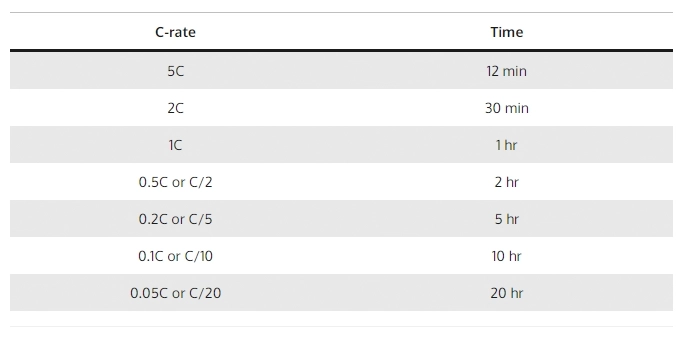

6.1 How Does the Discharge Rate Affect Battery Capacity?

The discharge rate directly impacts a battery’s effective capacity. Specifically, a higher discharge rate can decrease the available capacity, as the battery might not be able to maintain its maximum rated capacity during rapid discharges. Thus, when evaluating a battery’s usable capacity, the discharge rate must be taken into account.

6.2 What is the Discharge Rate of Electric Bicycle Batteries?

The discharge rate of electric bicycle batteries can vary based on the specific battery chemistry and design. Electric bikes typically employ lithium-ion batteries due to their high energy density and performance. These batteries generally demonstrate a discharge rate ranging from 1C to 4C or even higher. To illustrate, a 1Ah battery with a 10C discharge rate can deliver a continuous discharge current of 10 amps, whereas a 4C rate would allow for a continuous discharge current of 40 amps.

6.3 What is Considered a High Discharge Rate for Lithium Batteries?

For lithium batteries, a discharge rate typically considered “high” starts at 1C and above. However, it’s important to note that what’s deemed as a high specific discharge rate may vary based on the battery’s design, chemical composition, and intended application.

6.4 What is a Good Discharge Rate for Batteries?

An optimal C-rate for a battery hinges on the specific demands of its application. Typically, a discharge rate that facilitates efficient power transfer without overly stressing the battery is regarded as favorable. It’s recommended to consult the manufacturer’s specifications and guidelines to ascertain the best discharge rate for a particular battery.

6.5 How Do You Calculate the C-rate?

C-rate (C) = Charging or discharging current in amperes (A) / Battery’s rated capacity (Ah)

Let’s delve into an example involving a 100Ah lithium battery:

1C represents a discharge current of 100 amps, meaning the battery can provide a continuous discharge of 100 amps for one hour. In simpler terms, it can handle a load current of 100 amps for 60 minutes.

If we boost the C-rate to 2C, the discharge current becomes 200 amps. This signifies that the battery can now furnish a discharge current of 200 amps, but for a reduced duration. At a 2C rate, the battery can sustain a load current of 200 amps for 30 minutes or half an hour.

On the other hand, reducing the C-rate to 0.5C results in a discharge current of 50 amps. At a 0.5C rate, the battery can deliver a discharge current of 50 amps, thereby prolonging the discharge period. Under these conditions, the battery can support a load current of 50 amps for 2 hours or 120 minutes.

When assessing the performance and capacity of lithium batteries, the C-rate stands out as a crucial factor since it determines both the available discharge current and the corresponding discharge duration.

The reason why lithium batteries need protection is determined by their own characteristics. Since the material of the lithium battery itself determines that it cannot be overcharged, overdischarged, overcurrent, short circuited, and ultra-high temperature charge and discharge, the lithium battery components of the lithium battery will always appear with an exquisite protection board.

Ordinary lithium battery protection boards usually include control ICs, MOS switches, resistors, capacitors and auxiliary devices FUSE, PTC, NTC, ID, memory, etc. Among them, the control IC controls the MOS switch to turn on under all normal conditions to make the cell and the external circuit conduct, and when the cell voltage or loop current exceeds the specified value, it immediately controls the MOS switch to turn off to protect the cell’s Safety.

When the protection board is normal, Vdd is high, Vss and VM are low, DO and CO are high. When any parameter of Vdd, Vss, VM is changed, the level of DO or CO will be Changes.

1. Overcharge detection voltage: Under normal conditions, Vdd gradually rises to the voltage between VDD and VSS when the CO terminal changes from high level to low level.

2. Overcharge release voltage: In the charging state, Vdd gradually decreases to the voltage between VDD and VSS when the CO terminal changes from low level to high level.

3. Overdischarge detection voltage: Under normal conditions, Vdd gradually decreases to the voltage between VDD and VSS when the DO terminal changes from high level to low level.

4. Overdischarge release voltage: In the overdischarge state, Vdd gradually rises to the voltage between VDD and VSS when the DO terminal changes from low level to high level.

5. Overcurrent 1 detection voltage: Under normal conditions, VM gradually rises to the voltage between VM and VSS when DO changes from high level to low level.

6. Overcurrent 2 detection voltage: In the normal state, VM rises from OV to the voltage between VM and VSS when the DO terminal changes from high to low at a speed of 1ms or more and 4ms or less.

7. Load short-circuit detection voltage: Under normal conditions, VM starts from OV and rises to the voltage between VM and VSS when the DO terminal changes from high level to low level at a speed of 1μS or more and 50μS or less.

8. Charger detection voltage: In the over-discharge state, VM gradually decreases with OV to the voltage between VM and VSS when DO changes from low level to high level.

9. Current consumption during normal operation: Under normal conditions, the current (IDD) flowing through the VDD terminal is the current consumption during normal operation.

10. Over-discharge current consumption: In the discharging state, the current (IDD) flowing through the VDD terminal is the over-current discharge current consumption.