Lithium Battery Replacement – Quality Battery Wholesale Available

At MANLY Battery, we specialize in providing top-tier lithium battery replacement and battery wholesale solutions. Our products are tailored to meet your specific needs, offering customization in voltage, capacity, and design. With global certifications like UN38.3, IEC62133, UL, and CE, we ensure the highest standards of safety and performance. Our batteries come with a 10-year warranty, reflecting our commitment to quality and durability. Designed to operate efficiently in extreme temperatures ranging from -4°F to 167°F, our LiFePO4 batteries deliver 95% energy efficiency, surpassing traditional lead-acid options. For an enhanced user experience, we incorporate features such as Bluetooth connectivity and intuitive battery level displays. Choose MANLY Battery for reliable and customized energy solutions.

Filters

Application

Voltage

12v 400Ah Lithium Battery

- Cold-Weather Charging Safe

- Smart BMS, 20+ Protections

- Built for RV, Marine, solar Home etc.

12v 5Ah Lithium Lifepo4 Deep Cycle Battery

12v 150Ah Deep Cycle Lithium Battery

- 5760Wh High-Power Output

- Cold-Weather Auto Heating

- Plug-and-Play Installation

12 Volt Lithium Battery 100Ah

- 6000+ Deep Charge Cycles

- Extreme Weather Ready

- Bluetooth Real-Time Monitoring

12v Lithium Ion Battery 120Ah

- 1440Wh Solar Storage Power

- Best for RV Power Upgrade

- 20+ Advanced Safety Features

12V 80Ah LiFePo4 Battery

- Supports Four Charging Methods

- Engineered for Off-Grid Living

- Zero-Maintenance Battery Solution

12V 7Ah LiFePo4 Battery

- Ultra-Light Battery Housing

- Built for Micro Applications

- Consistent 12V Output Power

12v Lithium Battery 50Ah

Contact Us

To receive your email faster, please copy [email protected] and send your email directly, or fill out the form below.

Reliable and Durable Lithium Battery Replacement Features

Lithium Battery Manufacturer Committed to Quality

As a trusted Lithium Battery Manufacturer, MANLY Battery understands that customers seek lithium battery replacement solutions with performance that matches or exceeds the original. Advanced production technologies, including automated laser welding, high-power testing up to 200V and 500A, and high-temperature chambers reaching 100°C, ensure every battery meets stringent quality standards. Cells are meticulously graded with advanced sorting equipment to guarantee consistent voltage, internal resistance, and capacity, making them ideal for critical applications like AGVs, boats, and UPS systems.

Lithium Battery Replacement with Long-Lasting Battery Lifespan

MANLY Battery recognizes the importance of reducing replacement frequency. Each lithium battery replacement is designed to provide a superior Battery Lifespan of over 6,000 cycles and up to 10 years of service life. This durability ensures long-term reliability, lowering maintenance costs and offering consistent performance for systems that demand dependable power.

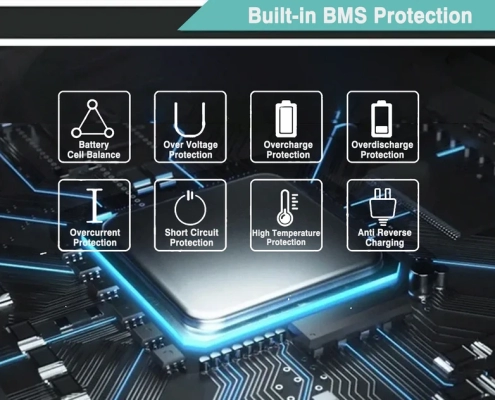

Battery Protection for Safe and Stable Operation

Safety and stability are at the core of every lithium battery replacement solution. MANLY Battery integrates advanced Battery Protection features, including safeguards against overcharging, over-discharging, and short circuits. Balanced circuitry ensures smooth operation, making these batteries a reliable choice for applications requiring continuous and safe power delivery.

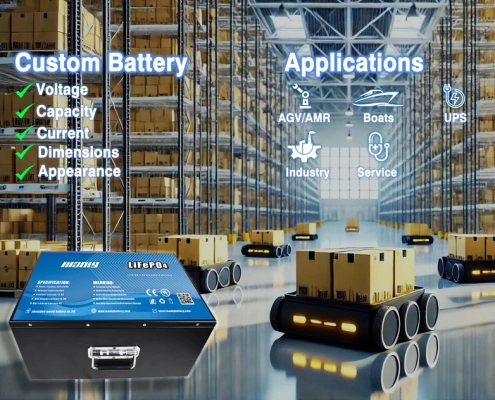

Custom Battery Configurations for Reliable Lithium Battery Replacement

To meet diverse customer needs, MANLY Battery provides lithium battery replacement options that are fully customizable in voltage, capacity, and design. These Custom Battery solutions are tailored for seamless integration into AGVs, industrial systems, medical device, solar lights, golf cart and boats, ensuring high compatibility, improved energy efficiency, and reduced energy waste.

Unmatched Packaging and Secure Transit for Superior Battery Protection

Each lithium battery is carefully packaged to ensure it arrives in perfect condition. Engineered shock-absorbing foam and industrial-grade reinforced cartons provide superior impact resistance, safeguarding the battery during transit. For heavier units, heavy-duty export-grade wooden crates are utilized, offering exceptional durability and protection against harsh shipping conditions. Every packaging solution is meticulously designed and rigorously tested to ensure the battery remains secure and intact throughout its journey, giving customers confidence in their investment.

MANLY Battery Replacement Specifications

These are just a few of MANLY Battery’s specs. For custom solutions, email us at [email protected]. Contact us today!

| Size(L*W*H) | Weight(Approx) | View | |

| 12v | |||

12V 9Ah Lithium Battery | 151*65*94 | 1.35kg | view |

12V 20Ah Lithium Battery | 181*77*167 | 2.35kg | view |

12V 24Ah Lithium Battery | 181*77*167 | 2.9kg | view |

12V 30Ah Lithium Battery | 165*175*125 | 3.9kg | view |

12V 48Ah Lithium Battery | 196*166*171 | 6.3kg | view |

12V 50Ah Lithium Battery | 230*138*208 | 6.5kg | view |

12V 80Ah Lithium Battery | 260*169*210 | 10.1kg | view |

12V 100Ah Lithium Battery | 330*172*214 | 13.1kg | view |

12V 150Ah Lithium Battery | 340*173*280 | 19.1kg | view |

12V 200Ah Lithium Battery | 522*240*220 | 23.8kg | view |

| 48v | |||

48V 50Ah Lithium Battery | 483*429*220mm | 48.2kg | view |

48V 100Ah Lithium Battery | 436*388*220 | 45Kg | view |

| Energy Storage | |||

5Kwh Energy Storage Battery | 643*520*165 | 52±2kg | view |

10Kwh Energy Storage Battery | 643*520*265mm | 90±2kg | view |

15Kwh Energy Storage Battery | 696*506*700mm | 190kg | view |

Trending Now